Cable dome and installation method thereof

An installation method and cable dome technology, applied in the field of building steel structures, can solve the problems of poor force balance of the overall structure and high labor intensity of high-altitude operations, and achieve the effects of convenient control of installation accuracy, reduction of high-altitude operations, and reduction of construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

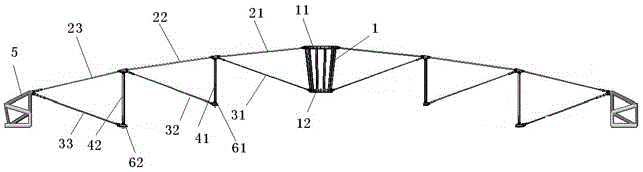

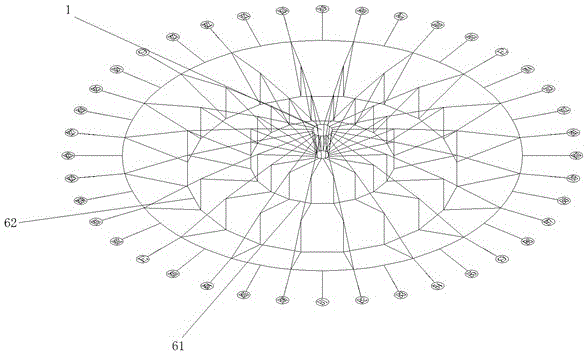

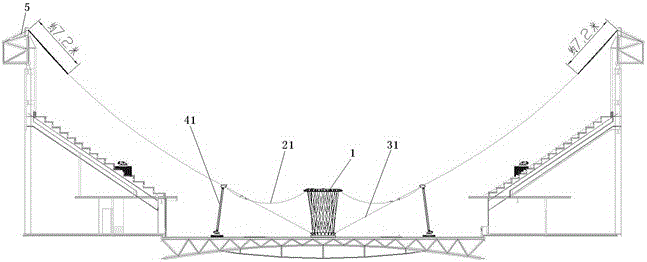

[0028] A cable dome, the main components involved include a notochord composed of three notochord units: a central pressure ring 1, an inner notochord 21, a middle notochord 22, and an outer notochord 23; , Inner strut 41, outer strut 42.

[0029] The central pressure ring 1 includes upper and lower rings, the diameter of the upper ring 11 is larger than that of the lower ring 12, and the two are fixed by splicing steel. Both the outer circumference of the upper ring 11 and the lower ring 12 have ear plates for connection with the cable system.

[0030] In this embodiment, the entire cable dome has a scale diameter of 71.2 meters and a height of 5.5 meters. The circumference is divided into 20 radial axes at equal intervals, and a notch cable is arranged at each axis position. One end of the inner notochord 21 is connected to the upper ring 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com