Composite plate type condensation cooler

A condensing cooler and composite technology, which is applied in steam/steam condensers, lighting and heating equipment, etc., can solve problems such as product separation, and achieve the effect of strong functionality, compact structure, and improved condensation efficiency and product yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

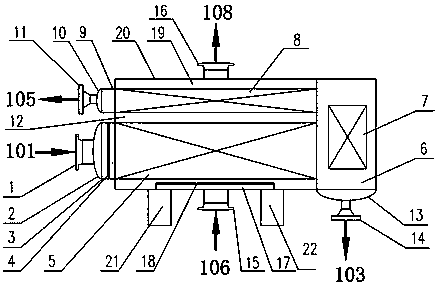

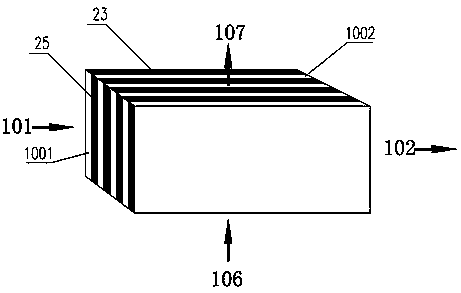

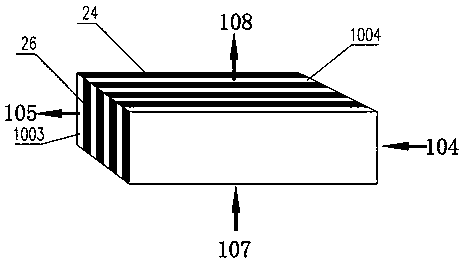

[0016] In order to better introduce the technical scheme of the present invention, below in conjunction with Figure 1 to Figure 4 The present invention is described in further detail.

[0017] Such as Figure 1-4 As shown, the gas phase medium is redistributed from the gas phase medium inlet 101 through the gas phase inlet flange 1, the gas phase inlet head 2, and the gas phase inlet pipe box 3 through the gas phase distributor 4 to improve the uniform distribution of the fluid and reduce the heat transfer dead zone . The gas phase medium enters the condensation zone heat exchange plate bundle 5, and the condensation zone hot medium flow channel 1001 exchanges heat with the cold medium in the condensation zone cold medium flow channel 1002, the condensable components in the gas phase medium condense into liquid, and the condensation zone heat medium flow The medium on the outlet side of channel 1001 is in a two-phase flow state, enters the separation chamber 6 through the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com