Three-dimensional comprehensive slab warping shape monitoring device and implementation method for early cement pavement

A technology of cement pavement and warped shape, which is applied to measuring devices, instruments, and the use of ultrasonic/sonic/infrasonic waves, etc. It can solve the problems of low precision, susceptibility to disturbance, and sensor susceptibility to disturbance, achieving high precision and good stability , ingeniously designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

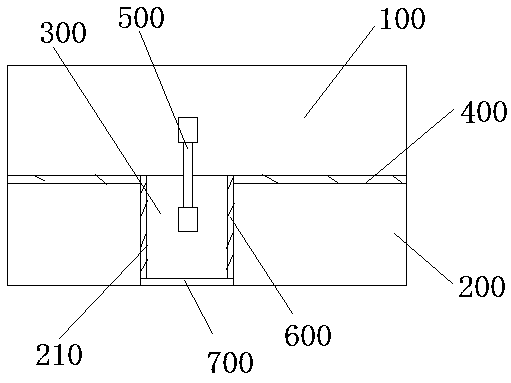

[0018] Embodiment 1: as Figure 1~2 As shown, in this embodiment, a device for monitoring the warpage shape of three-dimensional full-scale slabs in the early age of cement pavement is provided, including a concrete panel 100, a water-stabilizing base 200 is arranged under the concrete panel, and a water-stabilizing base 200 is set in the water-stabilizing base 200. There are several cylindrical concrete columns 300 embedded in the upper surface of the water-stabilized base, each cylindrical concrete column is provided with a vibrating wire strain sensor extending from the inside of the cylindrical concrete column to the concrete panel, and the water-stabilized base and the concrete panel An isolation film 400 is provided between the cylindrical concrete columns and the water-stabilized base to prevent the vertical deformation of the concrete panels;

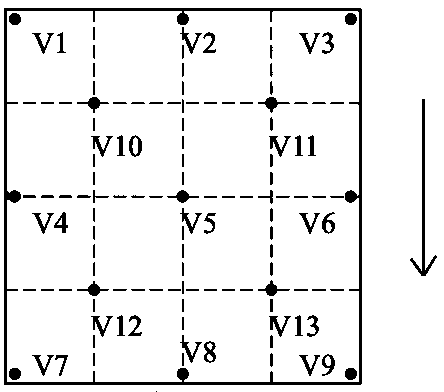

[0019] The concrete panel is provided with 13 measuring points, and each measuring point is provided with a vibrating wire str...

Embodiment 2

[0026] Embodiment 2: On the basis of Embodiment 1, in this embodiment, the gauge length of the vibrating wire strain sensor is 150 mm, the strain range is ±2500 με, and the accuracy is ±1 με, with high precision and wide application range; When the type strain sensor measures the displacement, the displacement is the product of the chord length of the strain gauge and the strain.

[0027] In this embodiment, 13 cylindrical concrete columns 300 are prefabricated first, 1 / 2 of the vertical length of the vibrating wire strain sensor is pre-embedded inside the prefabricated cylindrical concrete column, and then excavated on the water-stabilized base as required 13 slots for placing cylindrical concrete columns, the depth of the slots is consistent with the height of the cylindrical concrete columns, the cylindrical concrete columns are placed in the slots 210, the bottom of the cylindrical concrete columns and the bottom of the slots are made of epoxy resin Fixed to ensure firmnes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com