Rapid heavy-load workpiece conveying device based on static pressure air floating and detection method

A technology for heavy-duty workpieces and workpieces, which is applied in the field of rapid transportation devices for heavy-duty workpieces based on static pressure air-floating, can solve the problems of difficult long-distance transportation, high labor intensity of workers, safety accidents, etc., and achieves a self-weight ratio. Large, low repair and maintenance costs, high safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

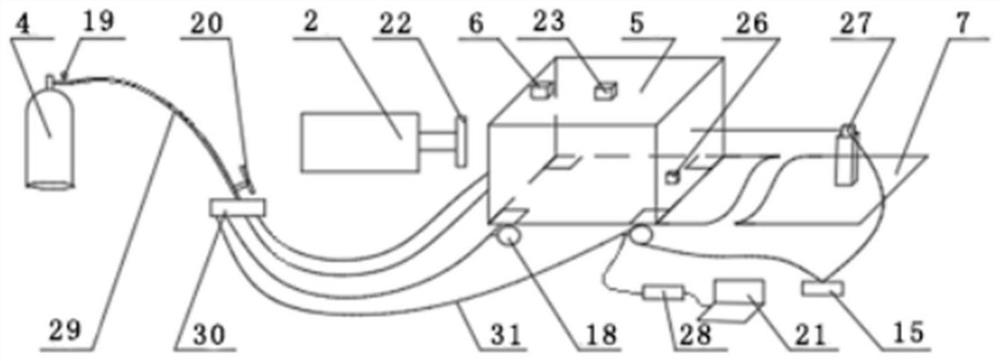

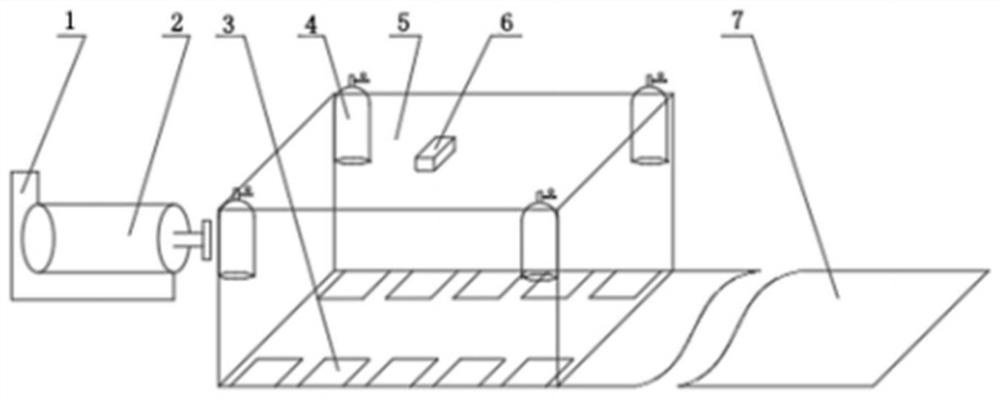

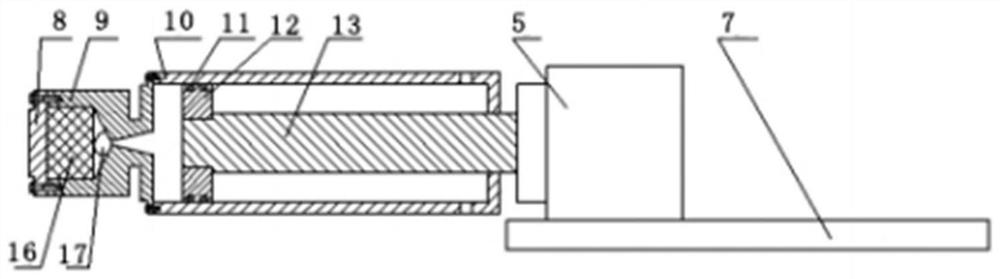

[0035] refer to Figure 1 to Figure 8 As shown, the present embodiment is based on a static pressure air flotation type heavy-duty workpiece rapid transport device, including a load workpiece 5, a track 7 arranged at the lower end of the load workpiece 5, a power system that cooperates with the load workpiece 5, a suspension system and a detection system. system; the power system includes a fixed table 1 arranged on the side of the load workpiece 5 and a gas actuator 2 arranged on the fixed table 1, and the output end of the gas actuator 2 is connected to the load workpiece 5 for providing The side thrust force of the load workpiece 5 moving horizontally on the track 7; the suspension system includes an air cushion assembly arranged on the lower end surface of the load workpiece 5, a gas cylinder 4 matching the air cushion assembly, and a spirit level 6 arranged on the upper end surface of the load workpiece 5; The power system, the suspension system and the detection system a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com