Magnetic connection structured configuration assembly with self-protection function

A technology for connecting structures and configuring components, which is applied in the direction of fixtures and mechanical equipment, can solve the problems of consuming manpower, material resources, time and financial resources, increasing production costs and production costs, and increasing the labor intensity of operators, so as to reduce operating costs. , saving raw materials, powerful expansion and compatibility effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

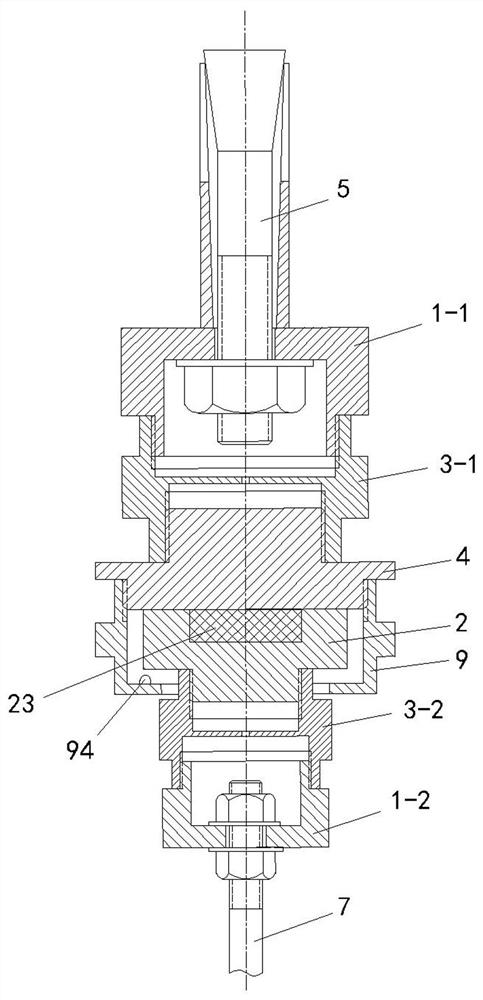

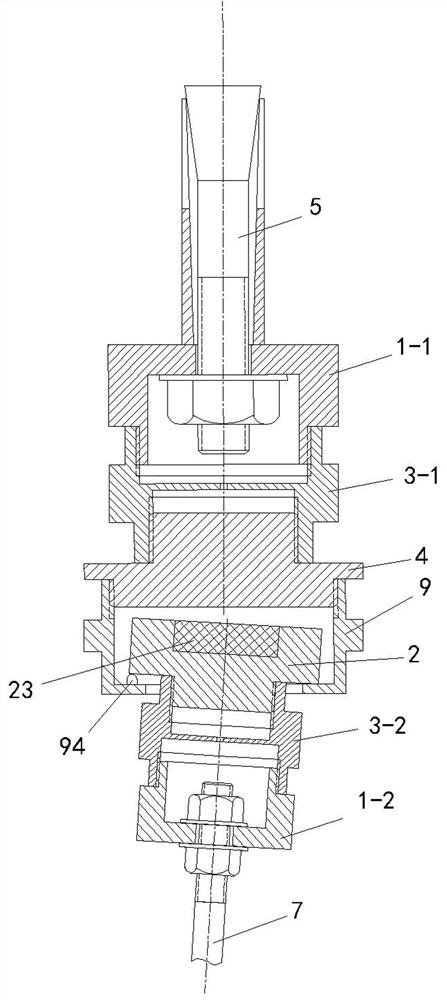

[0047] Such as figure 1 Shown: the self-protection magnetic connection structural configuration assembly of the present invention includes a first intermediate connecting piece 3-1, a second intermediate connecting piece 3-2, a first hole connecting piece 1-1, a second intermediate connecting piece 3-1, Two-hole connectors 1-2, magnetic connectors 2, magnetic-friendly connectors 4, and protective sleeves 9.

[0048] The first intermediate connector 3-1 has the same structure as the second intermediate connector 3-2, as image 3 , 4 As shown: one end of the first intermediate connector 3-1 has the first thread 31 of the intermediate connector, and the other end has the second thread 32 of the intermediate connector. Since the two pieces have the same structure, the second intermediate connector 3 will not be described again. -2 structure.

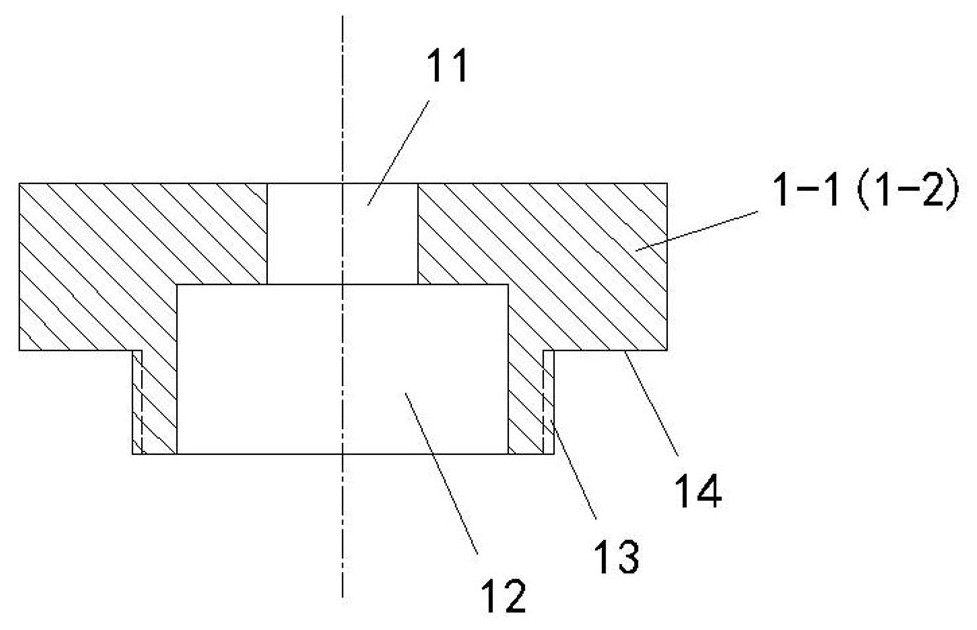

[0049] The first hole connector 1-1 has the same structure as the second hole connector 1-2, such as Figure 7 , 8 Shown: there is a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com