Carbon nano tube and graphene floor heating brick

A carbon nanotube and graphene technology, which is applied in the field of floor heating bricks, can solve the problems that the energy saving requirements of floor heating bricks cannot be met, the power of the electric heating layer increases, and the heating speed is slow, and achieves good energy saving effect, easy heat generation, and uniform heating speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

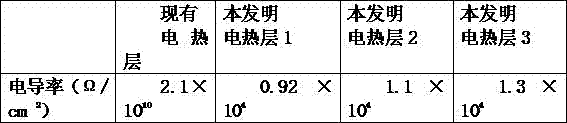

Embodiment 1

[0028] Preparation of electric heating layer: Firstly, graphite oxide is used to prepare expanded graphite, and one part of graphite is put into a muffle furnace at 1000°C, and the expanded graphite is obtained after holding for 15 minutes. Then modify the expanded graphite, that is, immerse the expanded graphite in an aqueous solution of 0.65 mol / L ammonium carbonate, and then drop the aqueous solution containing 0.32 mol / L ferric chloride into the above-mentioned solution containing the expanded graphite under stirring conditions, and stir. Stand for aging for 3 hours, filter, dry, roast at 650°C for 45 minutes, and grind into fine powder; finally, put the above fine powder in a chemical vapor deposition furnace, first pass argon into the furnace, and when the furnace temperature reaches 540°C Switch to hydrogen to reduce iron oxide. When the furnace temperature reaches 820 °C, 7.6 parts of acetylene are fed in again. After 3 hours of reaction, hydrogen is turned off, and arg...

Embodiment 2

[0030] Preparation of electric heating layer: Firstly, graphite oxide is used to prepare expanded graphite, and one part of graphite is put into a muffle furnace at 1000°C, and the expanded graphite is obtained after holding for 15 minutes. Then modify the expanded graphite, that is, immerse the expanded graphite in the aqueous solution of 0.3 mol / L ammonium carbonate, and then drop the aqueous solution containing 0.52 mol / L ferric chloride into the above-mentioned solution containing the expanded graphite under stirring condition, and stir Stand for aging for 3 hours, filter, dry, roast at 650°C for 45 minutes, and grind into fine powder; finally, put the above fine powder in a chemical vapor deposition furnace, first pass argon into the furnace, and when the furnace temperature reaches 540°C Switch to hydrogen to reduce iron oxide. When the furnace temperature reaches 820 °C, add 9 parts of acetylene, react for 2 hours, turn off the hydrogen, and introduce argon to cool down ...

Embodiment 3

[0032] Preparation of electric heating layer: Firstly, graphite oxide is used to prepare expanded graphite, and one part of graphite is put into a muffle furnace at 1000°C, and the expanded graphite is obtained after holding for 15 minutes. Then modify the expanded graphite, that is, immerse the expanded graphite into the aqueous solution of 0.85 mol / L ammonium carbonate, and then drop the aqueous solution containing 0.15 mol / L ferric chloride into the above-mentioned solution containing the expanded graphite under stirring condition, and stir Stand for aging for 3 hours, filter, dry, roast at 650°C for 45 minutes, and grind into fine powder; finally, put the above fine powder in a chemical vapor deposition furnace, first pass argon into the furnace, and when the furnace temperature reaches 540°C Switch to hydrogen to reduce iron oxide. When the furnace temperature reaches 820 °C, add 5 parts of acetylene, react for 4 hours, turn off hydrogen, and introduce argon to cool down n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com