Low height electromagnetic relay

An electromagnetic relay, low-height technology, applied in the direction of electromagnetic relays, electromagnetic relay details, relays, etc., can solve the problems of unreachable height and two major systems, and achieve the effect of improving flexibility, reducing height, and sufficient flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

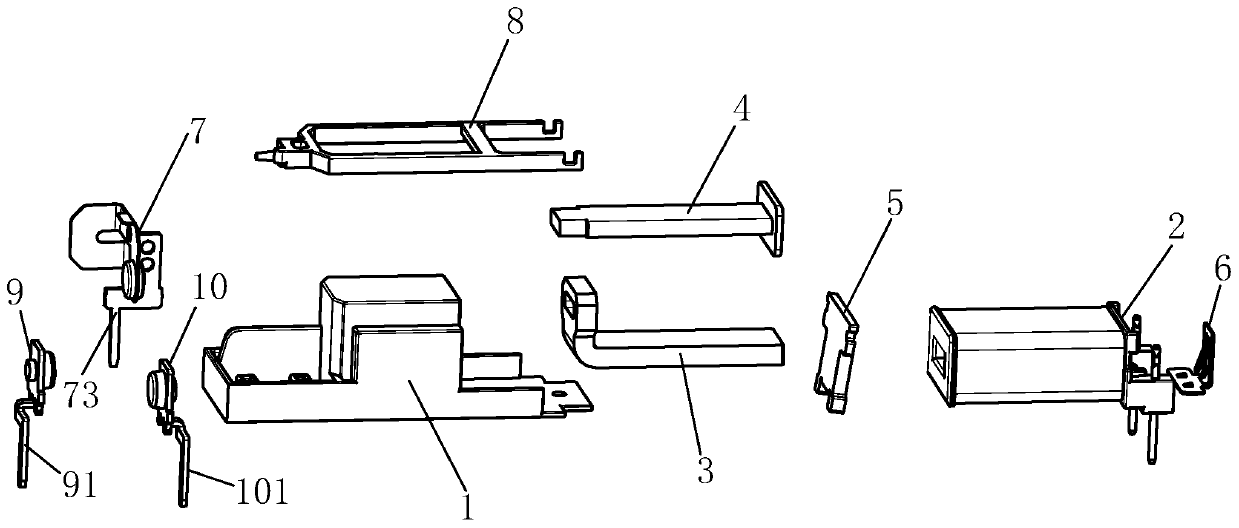

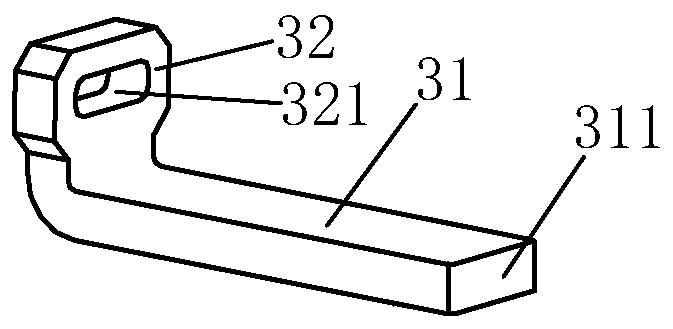

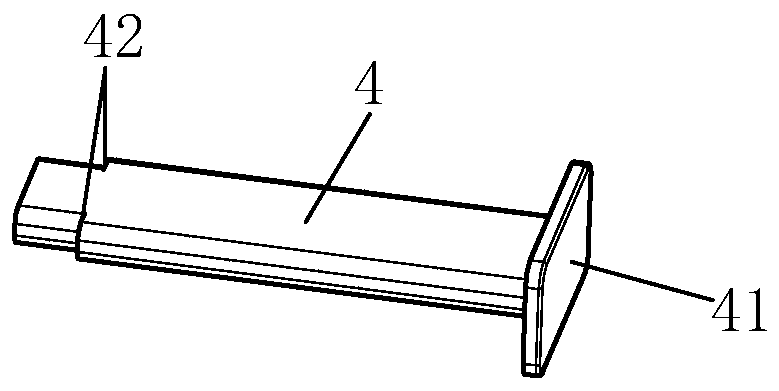

[0035] Examples, see Figure 1-Figure 11 As shown, a low-height electromagnetic relay of the present invention includes a base 1, a coil frame 2 wound with an enameled wire, an iron core 3, a yoke 4, an armature 5, a compression spring 6, a moving spring 7 with pins 73, Static spring with pins, push card 8, coil frame 2 is horizontally installed on base 1; yoke 4 is T-shaped, and yoke 4 is horizontally fitted on coil frame 2; iron core 3 is L type, and the horizontal side 31 of the iron core 3 is worn in the bobbin 2, the end face of the horizontal side 31 of the iron core 3 is a knife-edge surface 311, the vertical side 32 of the iron core 3 is connected to the tail of the yoke 4, and the yoke The end face of the iron 4 head is a pole shoe surface 41. The position of the armature 5 is limited by the compression spring 6 , so that the armature 5 corresponds to the joint between the knife-edge surface 311 of the iron core 3 and the pole shoe surface 41 of the yoke 4 . The con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com