SMT heavy industry nozzle

A nozzle and heavy industry technology, applied in electrical components, printed circuit manufacturing, electrical components, etc., can solve the problems of unreachable components, shorten heating time, and fix component space, improve work efficiency, speed up heat accumulation time, and avoid temperature drain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

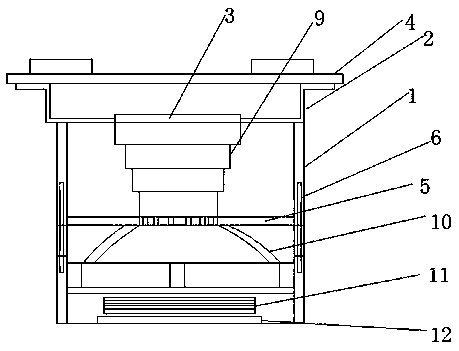

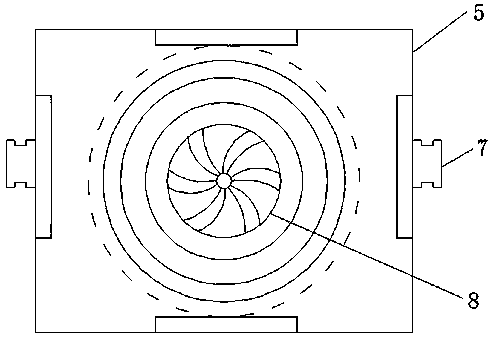

[0029] Such as figure 1 with figure 2 As shown, an SMT heavy industry nozzle includes a shell, the top of the shell is provided with a cover plate, the cover plate is connected with a connector, the connector can be connected with the air outlet of the heater, and the cover plate is provided with an air inlet , The housing is provided with a partition, two sides of the partition are respectively provided with sliders, and the two side walls of the housing and the slider are respectively provided with vertically arranged sliding grooves, Sliding up and down in the sliding groove makes the partition move up and down in the housing. A through hole is opened in the middle of the partition. The through hole is aligned with the air inlet in the cover plate. An impeller is installed in the through hole. There is a corrugated pipe connected to the air inlet, and the inner side of the corrugated pipe is lined with a layer of glass fiber cloth. The glass fiber cloth layer can play a rol...

Embodiment 2

[0031] A rework heating method for SMT heavy industry nozzles, the specific plan is as follows:

[0032] Step 1. Put the component into the component container in the SMT heavy industry nozzle, place the soldered part on the component facing the heating inlet in the component container, and adjust the partition in the shell to the closest to the component Position, turn on the heater to heat the component, record the time required for the solder attached to the component to reach the melting point, and take out the component after recording;

[0033] Step 2. Take the same type of component as in Step 1 and put it into the component container again, adjust the partition in the housing to the position farthest away from the component, turn on the heater to heat the component, and record the solder attached to the component The time required to reach the melting point, take out the component after recording;

[0034] Step 3. After repeating the process of step 1 and step 2 each 5 times...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com