Temperature compensation kettle cover and temperature compensation kettle of irradiation monitoring pipe test device

A technology of radiation supervision tube and temperature compensation, which is applied in the field of electric power, can solve the problems affecting the temperature uniformity of the cavity, and achieve the effects of easy manual operation, accurate and uniform temperature, and prevention of temperature loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

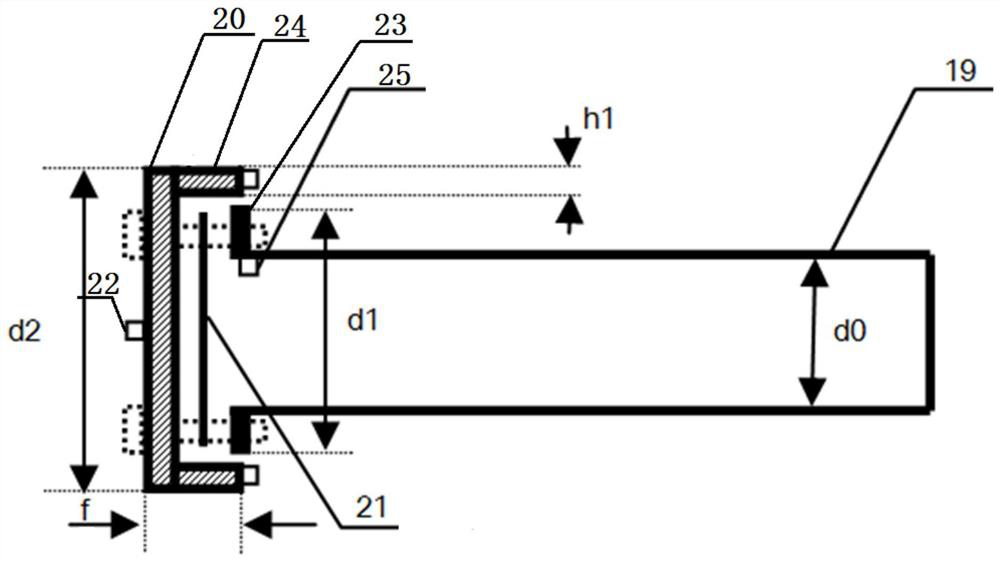

[0041] Such as figure 1 , figure 2 As shown, the present invention is a temperature-compensated kettle lid of a radiation supervisory tube test device, the temperature-compensated kettle lid includes a kettle lid 20 and a plurality of first compensation temperature sensors 22 arranged on the kettle lid 20, the kettle lid At least three first compensation temperature sensors 22 are evenly arranged on the outside of the circumferential surface of the cover 20, and a first compensation temperature sensor 22 is arranged at the middle position outside the kettle cover 20; the above-mentioned first compensation temperature sensors 22 are respectively connected to an external automatic control system, Real-time test the temperature of each first compensation temperature sensor 22;

[0042] The temperature compensation kettle cover is used to connect with the kettle body 19 that cooperates with it. When the difference between the average value of each of the first compensation tempe...

Embodiment 2

[0051] Such as figure 1 , figure 2 As shown, the difference between this embodiment and Example 1 is that a temperature compensation kettle of a radiation supervision tube test device includes a kettle body 19, a temperature compensation plate 21 and a radiation supervision tube described in Example 1. The temperature compensation kettle cover of the test device, the temperature compensation plate 21 is arranged between the inner side of the kettle cover 20 and the kettle body 19; the kettle body 19 is a cylindrical chamber placed horizontally, one side of the kettle body 19 is closed, and the other side is closed. The side opening, the kettle cover 20 is snapped on the opening side of the kettle body 19, so that the kettle cover 20 is sealed and connected with the kettle body 19;

[0052] The inner wall of the kettle body 19 is provided with a second compensating temperature sensor 25 near the kettle cover 20; in the described kettle body 19, several temperature sensors 13 ...

Embodiment 3

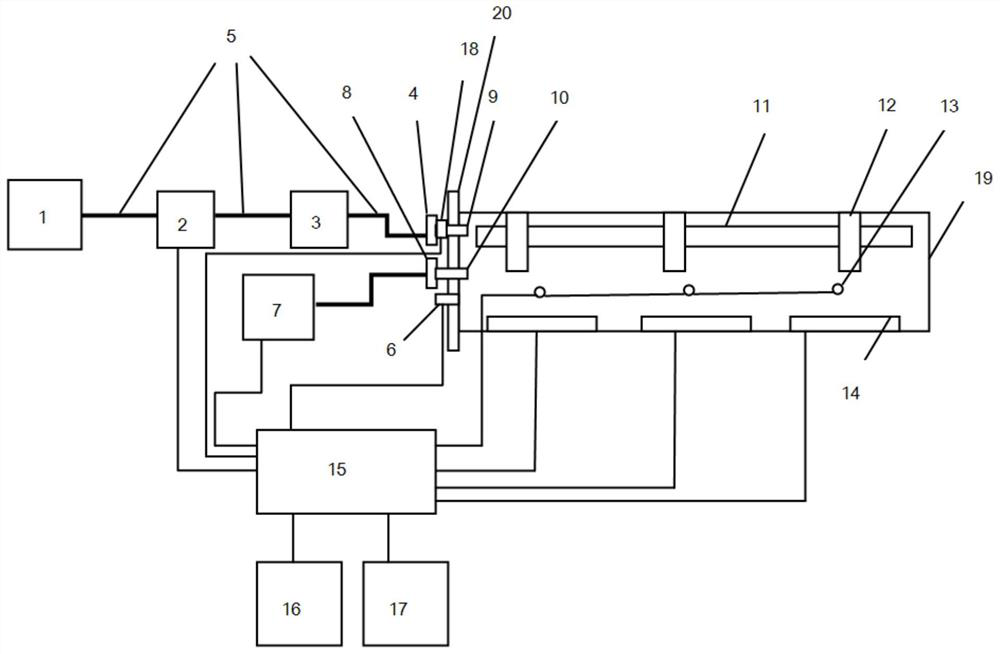

[0064] Such as figure 1 , figure 2 As shown, the difference between this embodiment and embodiment 1 is that, specifically as figure 2 As shown, a kind of radiation supervisory tube test device comprises a high-temperature autoclave, a fixing device 12, a vacuum device, a booster device, a heating device and an automatic control system, and the vacuum device and the booster device are all connected to the high-temperature autoclave; The vacuum device, booster device and heating device are all connected with the automatic control system;

[0065] The high-temperature autoclave includes a kettle body 19 and a kettle cover 20. The kettle body 19 is a cylindrical chamber placed horizontally. One side of the kettle body 19 is open and the other side is closed. The kettle body 20 is connected to the kettle body. 19 opening to form a closed space; the irradiation supervision tube 11 is sent into the kettle body 19 from the opening of the kettle body 19, and is installed inside th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com