Straw smashing device of cotton stalk pulling pulverizer

A technology of straw crushing and pulverizer, which is applied in the direction of agricultural machinery and tools, cutting equipment, application, etc., and can solve problems such as incompleteness, decay and returning to the field, and unfavorable stems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

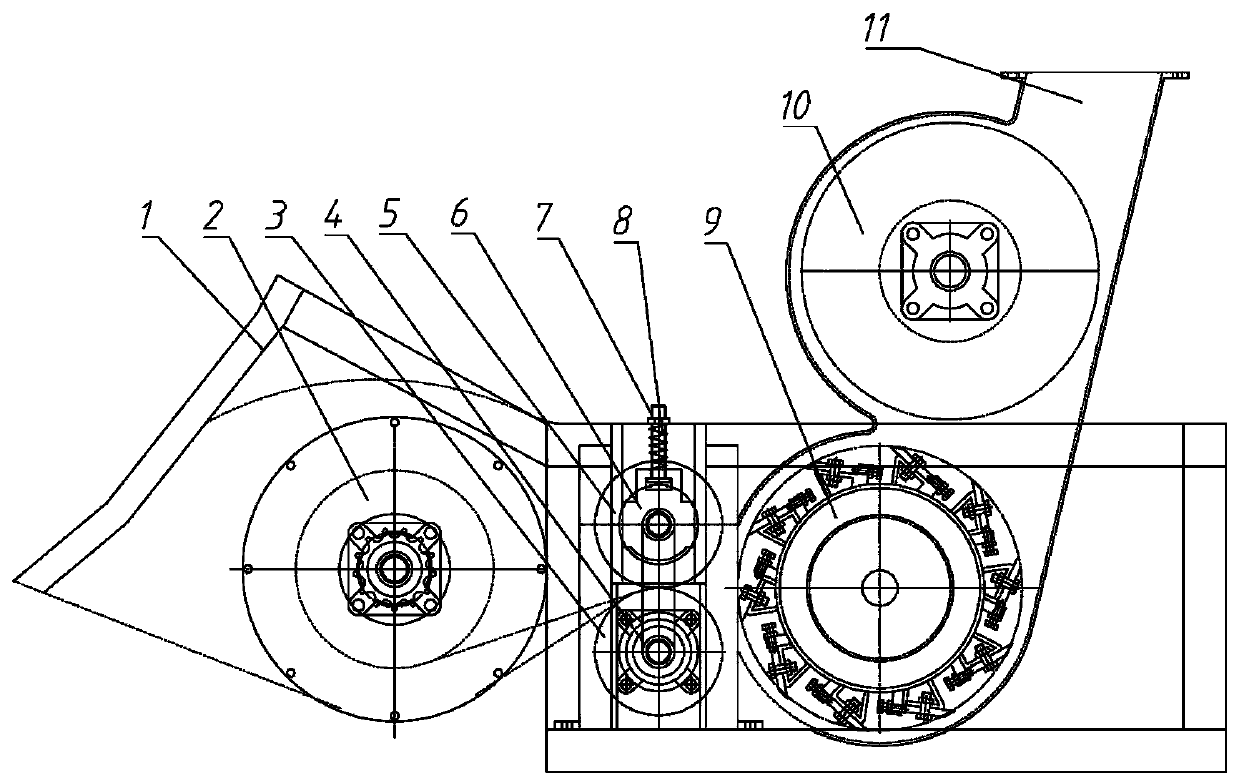

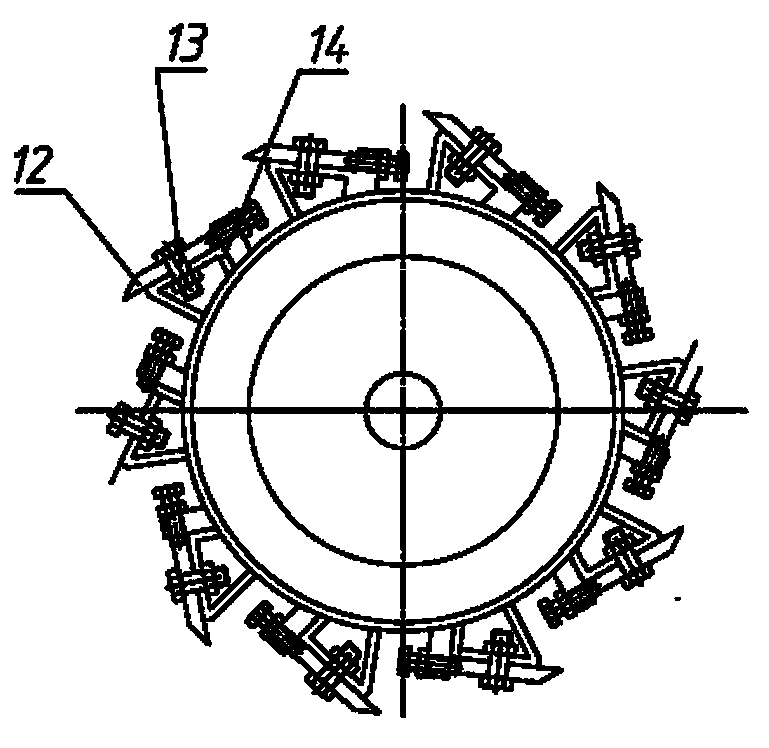

[0013] A straw crushing device of a cotton pull rod crusher, such as figure 1 , figure 2 As shown, including the frame 1, the auger conveyor roller 2 is set in the front of the frame 1, and the center of the frame behind the auger conveyor roller 2 is horizontally set up and down with two pairs of roller clamping and squeezing conveying mechanisms. The clamping and squeezing conveying mechanism includes a lower clamping roller 3, an upper clamping roller 5, a bearing seat 4, a sliding bearing seat 6, an adjusting bolt 7, and a tension spring 8. The lower clamping roller 3 is installed on the frame through the bearing seat 4 The upper clamping roller 5 is installed on the frame through the sliding bearing seat 6. An adjusting bolt 7 and a tension spring 8 are installed between the sliding bearing seat 6 and the frame 1. The axial roller surfaces of the upper and lower clamping rollers are uniform Rectangle ribs are distributed; the rear of the frame 1 is equipped with a cutting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com