Efficient fine crusher distributor

A fine crusher and feeder technology, applied in grain processing and other directions, can solve the problems of uneven distribution, affecting the crushing effect of large-scale fine crushers, and material concentration, so as to improve the fine crushing effect, prevent uneven accumulation, and prolong service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the present invention.

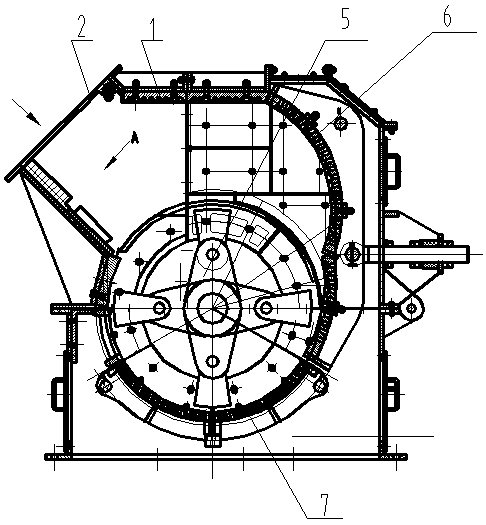

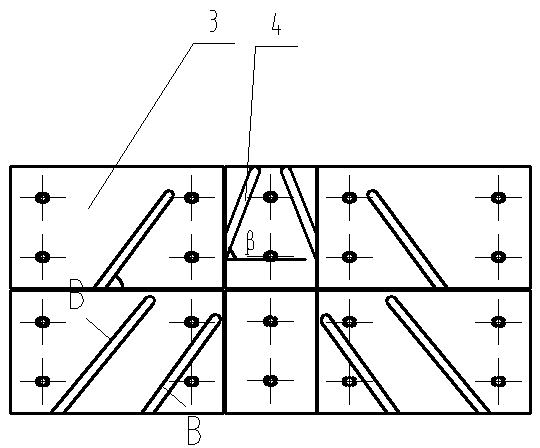

[0018] Such as figure 1 The fine crusher shown includes a shell, a feed port 2, a feed port lining plate 3, a distribution rib 4, a fine crusher rotor 5, a counterattack grate plate 6 and a discharge grate plate 7. The feed port is the material entry part of the fine crusher 1, which accepts the input of materials from the belt conveyor into the inside of the fine crusher 1. The fine crusher rotor 5 is installed in the fine crusher 1, and is used to support the hammer head of the crushed material and the crushing device driven by the motor to rotate at a certain speed. The counter-attack grate plate 6 is a screening device for screening materials smaller than the grate plate grate slit. The discharge grate plate 7 is a screening device for screening materials smaller than the grat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com