Food processor beneficial to crushing and cleaning

A food processor and crushing cup technology, applied in the field of household electrical appliances, can solve the problems of limited crushing efficiency and effect, and achieve the effects of improving the crushing effect, improving the turbulence effect, and improving the fine crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

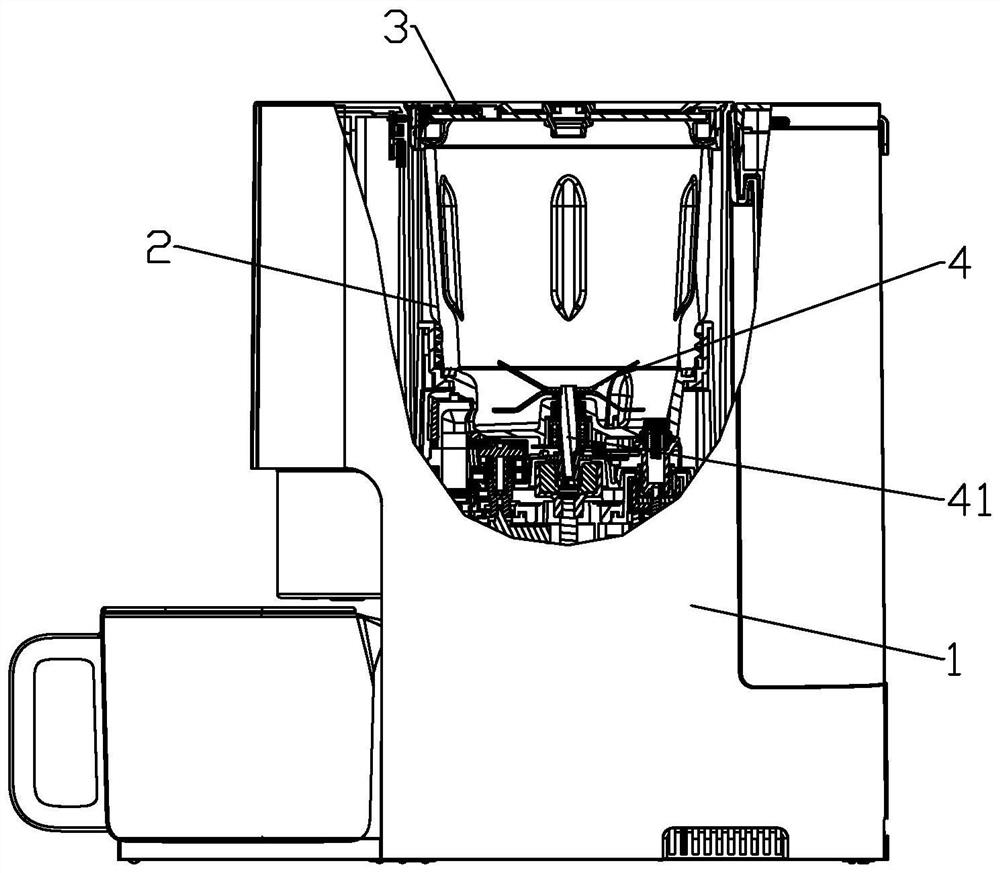

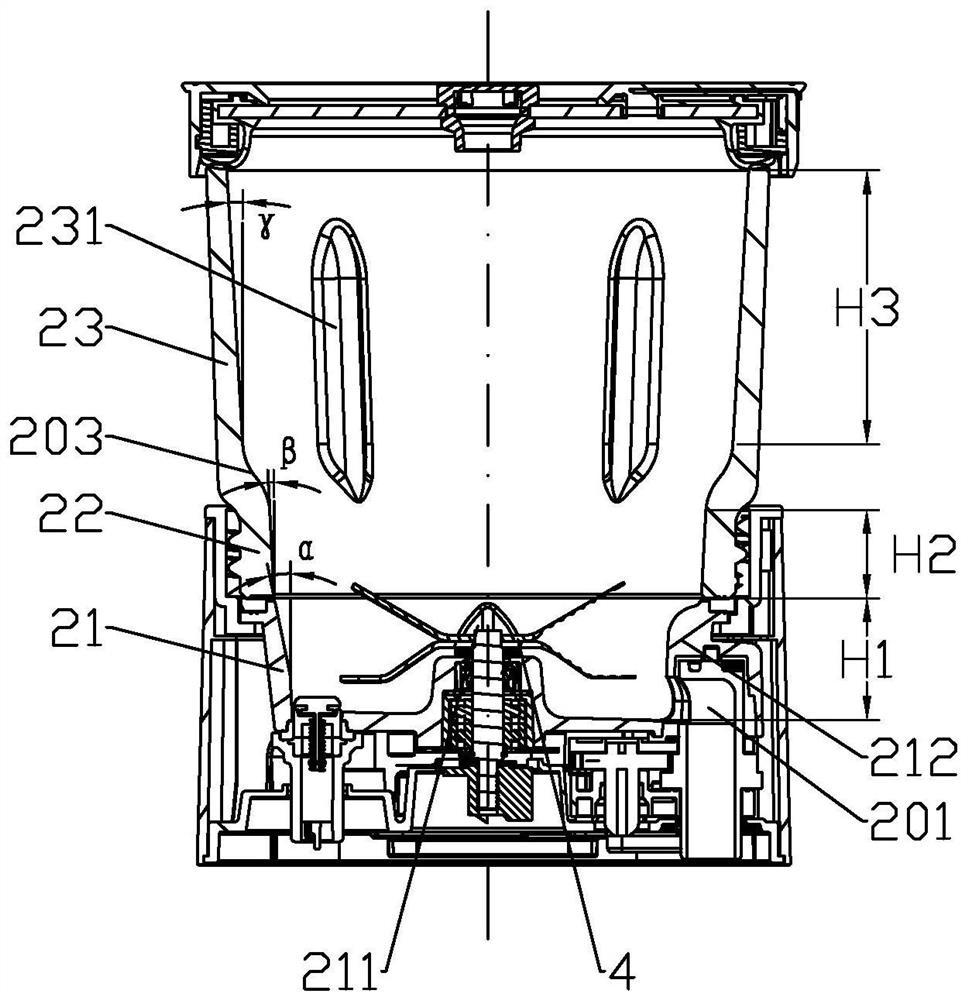

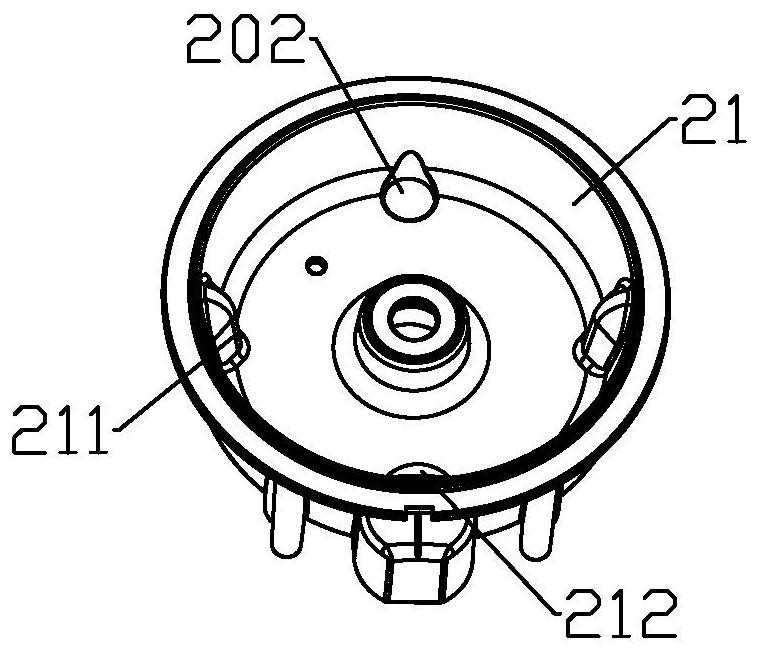

[0026] like figure 1 As shown, the present invention provides a food processor that is beneficial to crushing and cleaning, including a body 1 and a crushing assembly arranged on the body 1, the crushing assembly includes a crushing cup body 2, a crushing cup cover 3 and a crushing cutter 4, and the crushing cup cover 3 Installed on the top of the crushing cup body 2, the bottom surface of the crushing cup body 2 is provided with a cutter shaft 41, and the crushing cutter 4 is installed on the cutter shaft 41. In an embodiment, the crushing cup body 2 is detachably connected with the body 1. combine figure 2 See, the crushing cup body 2 comprises crushing section 21, ascending section 22 and spoiler section 23 successively from bottom to top, and the inner diameter of crushing section 21 is smaller than the inner diameter of ascending section 22 to form a small space for crushing, and crushing cutter 4 is located in crushing section 21 , the inner diameter of the ascending s...

Embodiment 2

[0037] like Image 6 and Figure 7 As shown, in this embodiment, there are two first spoiler ribs 211, and the two first spoiler ribs 211 are symmetrically distributed about the line connecting the slurry discharge port 201 and the axis of the cutter shaft 41, and the two first spoiler ribs The central angle of the rib 211 with the center of the crushing cup body 2 as the center is 120°, and the central angle is relatively large, which can reduce the risk of liquid overflow or splash due to excessive turbulence of the liquid flow during the crushing or cleaning process. The second spoiler ribs 231 are evenly distributed There are six, and two of the second spoiler ribs 231 are aligned with the first spoiler ribs 211, which is beneficial to improve the upward stroke of the liquid in the crushing and cleaning process, and can effectively wash the crushing cup cover 3 to improve the cleaning effect.

[0038] For other content not described in this embodiment, reference may be ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com