Ultrasonic wave driving device with self-correcting function

A driving device, ultrasonic technology, applied in the direction of spraying device, liquid spraying device, etc., can solve the problem of unoperated resonance frequency of the ultrasonic nozzle, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Exemplary embodiments of the present invention are described in detail below with reference to the accompanying drawings, and it is not intended to limit the technical principles of the present invention to specific disclosed embodiments, but the protection scope of the present invention is only limited by the claims, covering substitutions, modifications and equivalents.

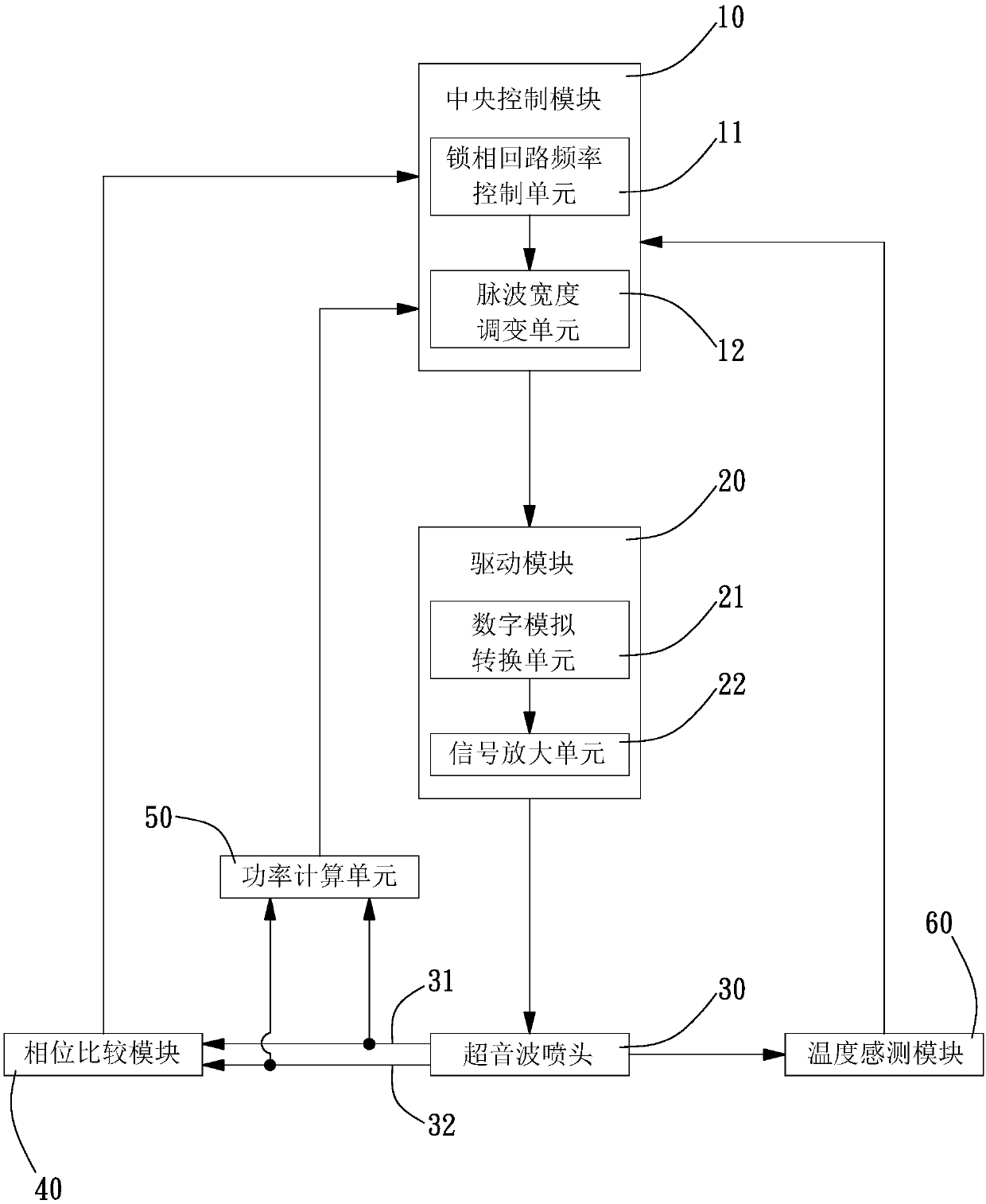

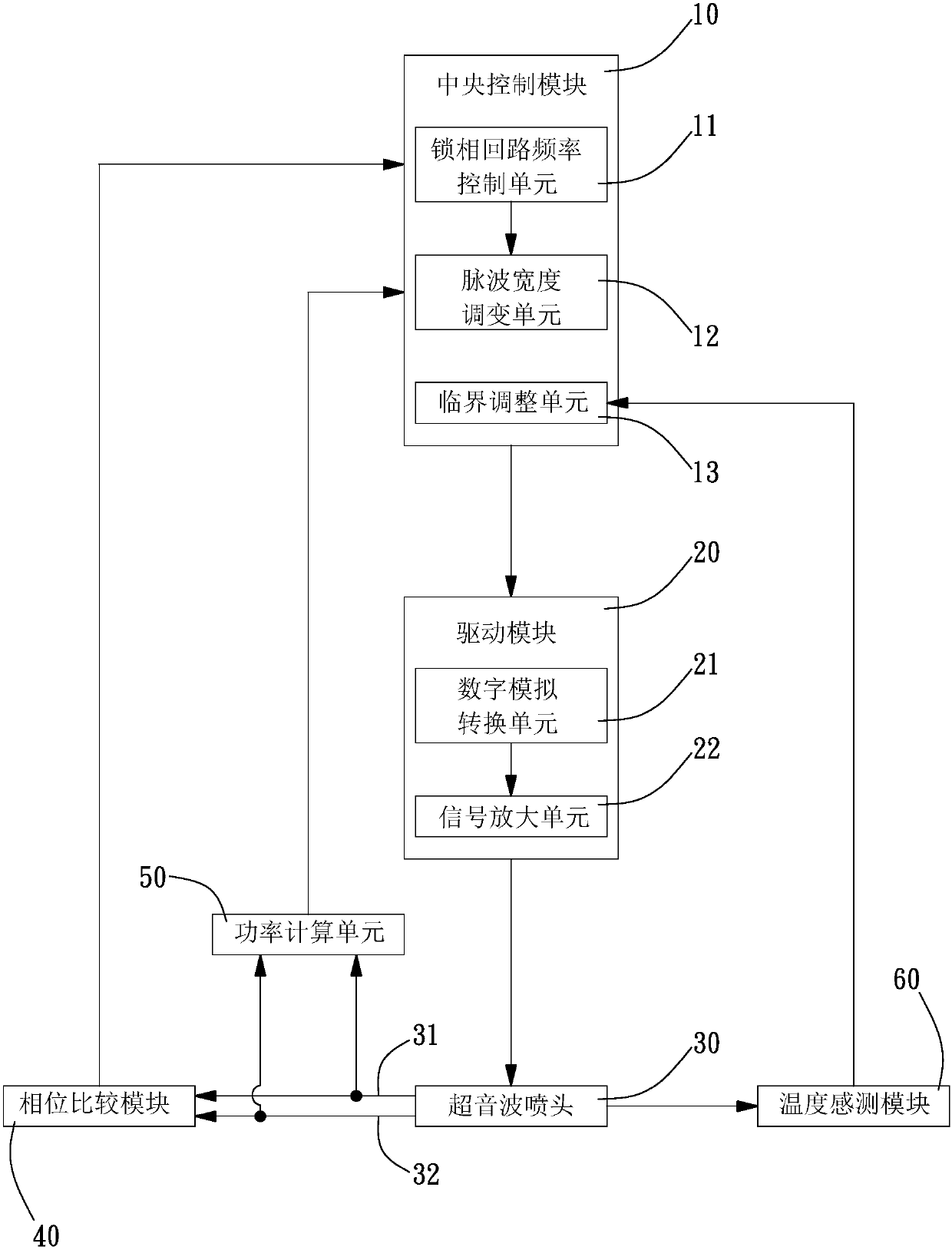

[0030] see figure 1 , the present invention is an ultrasonic driving device with self-correction function, comprising a central control module 10, a driving module 20 electrically connected to the central control module 10, an ultrasonic driving module electrically connected to the driving module 20 The spray head 30 and a phase comparison module 40 electrically connected the ultrasonic spray head 30 and the central control module 10 . The central control module 10 sets the frequency and power of the ultrasonic oscillation and outputs a drive signal. In the present embodiment, the central control mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com