High Frequency Vibration Laser Welding Process Based on Electromagnetic Vibrator

A technology of laser welding and high-frequency vibration, which is applied in the field of material processing engineering, can solve problems such as unfixed direction, difficult vibration frequency, and vibration energy dispersion, and achieve the effects of eliminating residual stress, improving comprehensive performance, and increasing vibration frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

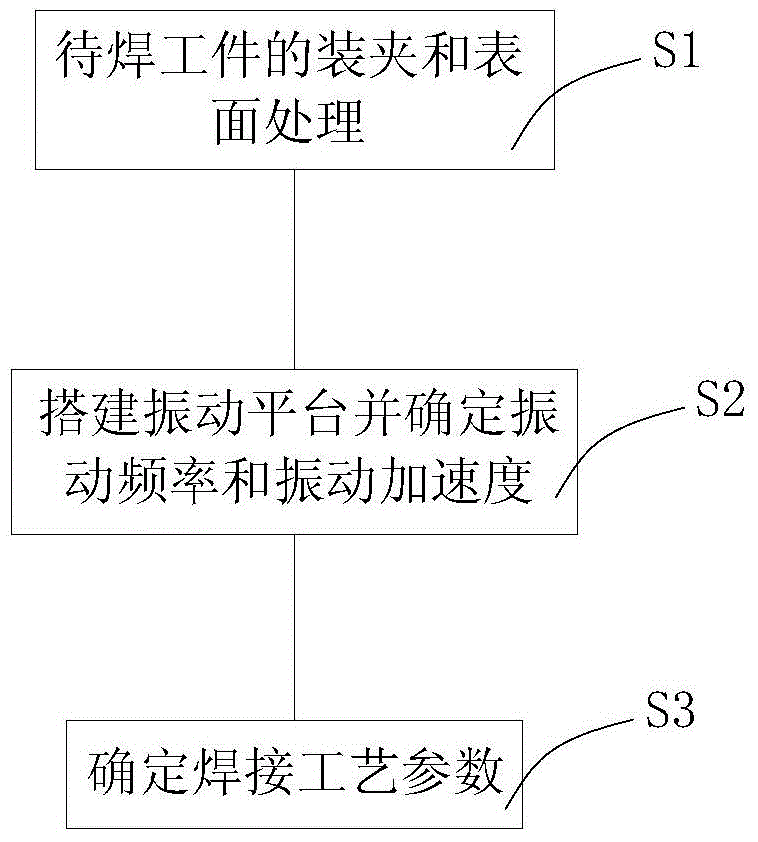

[0035] In this embodiment, the 316L austenitic stainless steel plate of 170 (length) × 100 (width) × 3 (thickness) mm is used for laser self-fusion welding with IPG YLS-5000 high-power fiber laser on the working platform, and its specific operation is according to figure 1 Follow the steps shown in .

[0036] S1: Clamping and surface treatment of workpieces to be welded

[0037] Rigidly fix the backing plate and the stainless steel plate at the center of the working platform, and use a steel block to separate the backing plate and the stainless steel plate to prevent the stainless steel plate from being welded to the backing plate. The surface of the stainless steel plate is polished with 100# coarse sandpaper to remove the surface oxide layer and stains to prevent inclusions and pores in the molten pool during welding, and finally cleaned with ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com