Hair cutting appliance, cutting unit, static knife structure and machining process for static knife structure

A processing technology and hair cutting technology, which is applied in metal processing and other directions, can solve problems such as complex processing technology of fixed blades, and achieve the effect of ensuring shaving effect, ensuring comfort and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

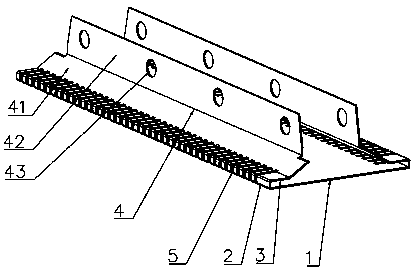

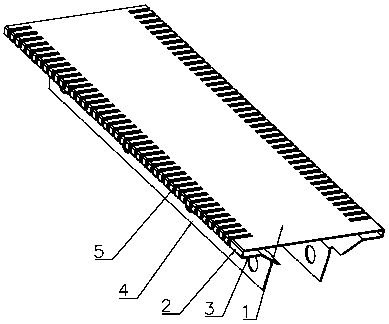

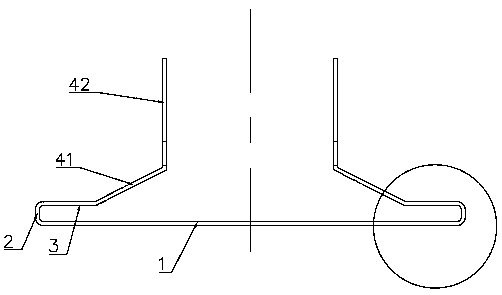

[0032] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

[0033] Such as Figure 1-4 As shown, a static knife structure is used for a linear reciprocating hair cutting appliance, which is integrally formed of metal material, including a plane contact part 1, a connecting part 2, a limiting part 3 and a mounting part 4.

[0034] The plane contact part 1 has a smooth surface and a rectangular structure, which can better contact with the skin, is smooth and smooth, and ensures the comfort and effect of shaving.

[0035] The limiting part 3 is arranged on the left and right sides of the planar contact part 1, the limiting part 3 is parallel to the planar contact part 1, and is connected by the connecting part 2, the distance between the limiting part 3 and the planar contact part 1 A space that can accommodate the moving knife is formed between them. At the same time, the positions corresponding to the limit parts 3 o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Arc radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com