Method and an elevator control unit for controlling a doorstep gap of an elevator and an elevator

A technology of elevator control and elevator, which is applied in the direction of elevators, transportation and packaging, elevators, etc. in buildings, and can solve the problems of large doorstep gaps, elevator cars that cannot be very close to or touch the stair platform floor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

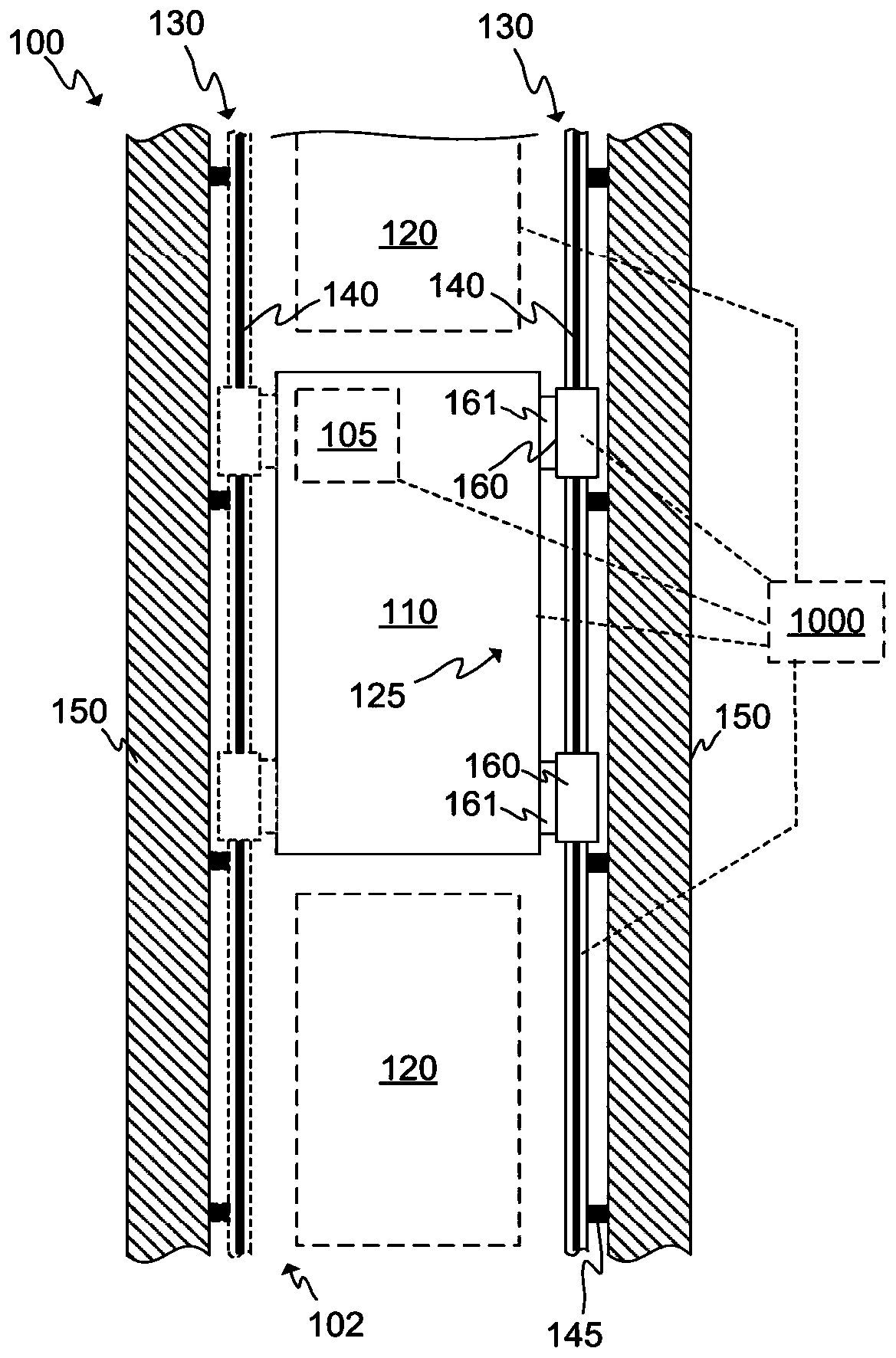

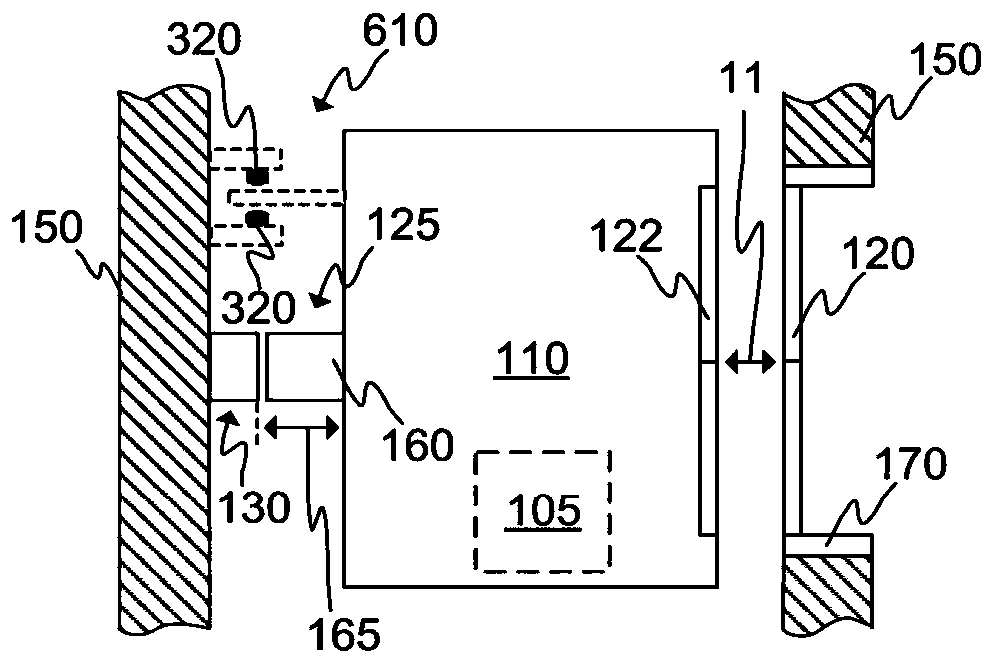

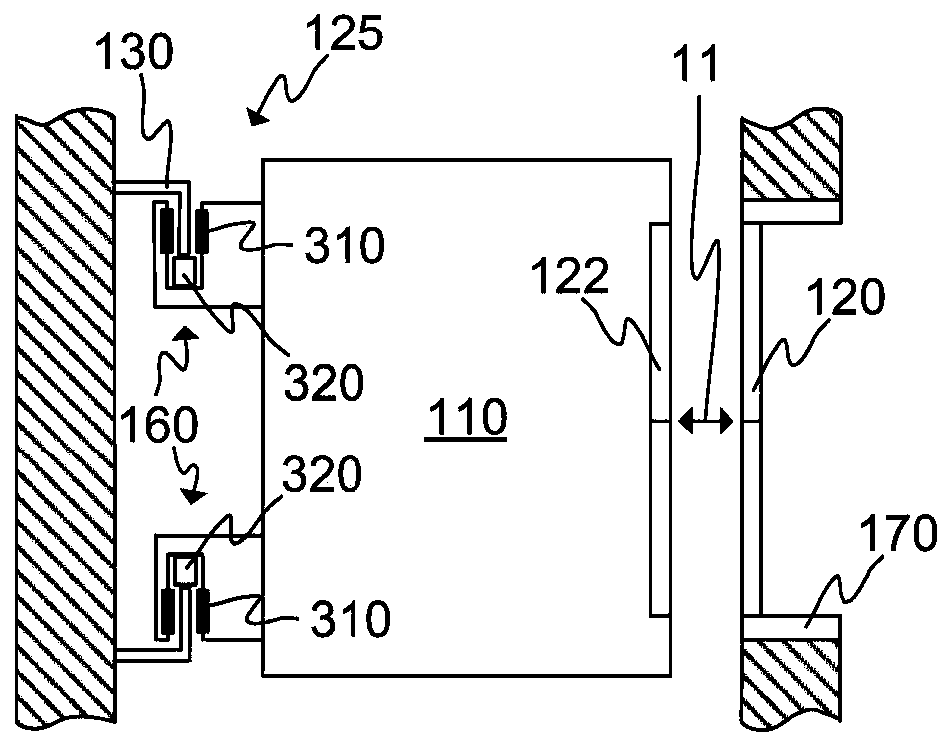

[0042] figure 1 An elevator 100 according to an embodiment of the invention is schematically shown by means of a cross-sectional side view. Elevator 100 may include an elevator shaft 102 and an electric linear motor 125 coupled to elevator car 110 . Electric linear motor 125 is configured to move elevator car 110 in elevator hoistway 102 . Elevator 100 may preferably include at least two landing levels including landing doors 120 and / or openings 120 .

[0043] Elevator car 110 may preferably be designed to serve a landing level during normal operation of elevator 100 . Movement of elevator car 110 may generally be upward and downward. However, the electric linear motor 125 may also be arranged to move the elevator car 110 in a horizontal direction or in any other direction. This can be achieved by arranging one or more stator beams 130 to be aligned with respect to a desired direction. The stator beam 130 may comprise one or more stators 140, or may be substantially the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com