Arm type water suction pump with telescopic bending structure

A water pump and arm technology, applied in the field of arm water pumps, can solve the problems of inconvenient operation, reduced work efficiency, and long working hours, and achieve the effects of easy portability, improved efficiency, and reduced working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

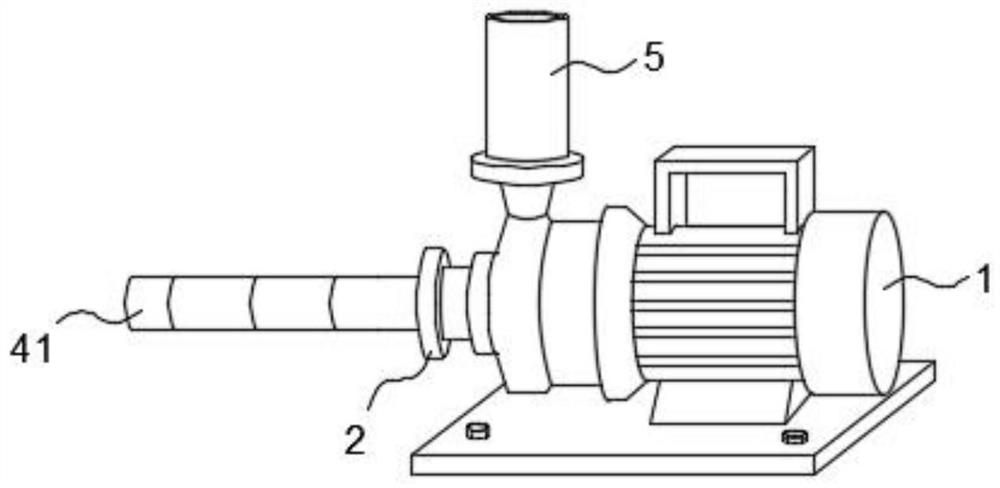

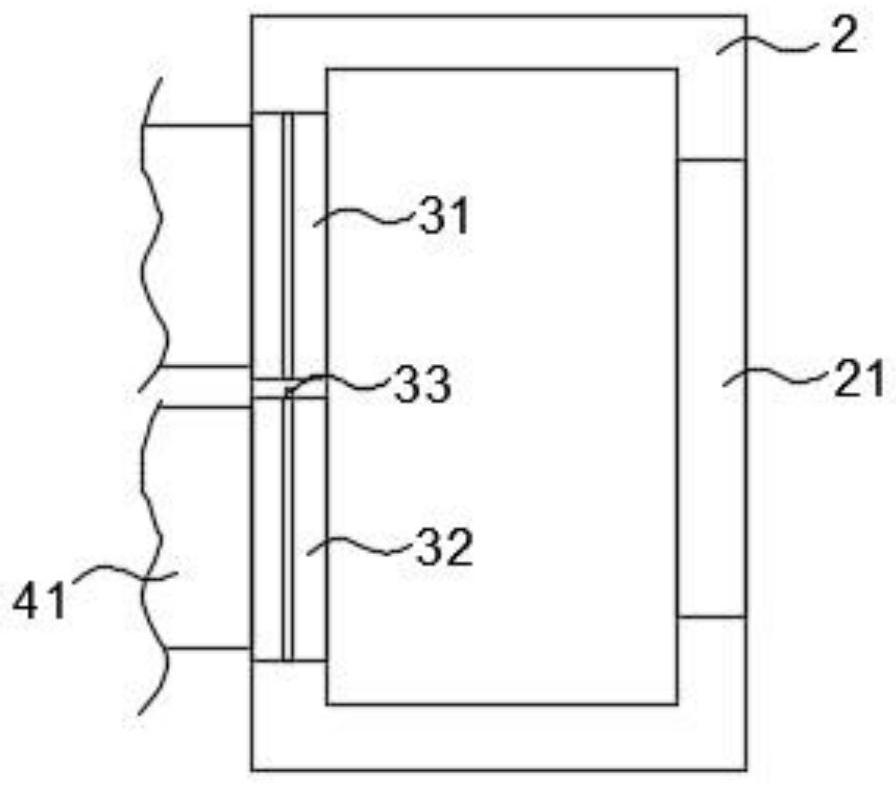

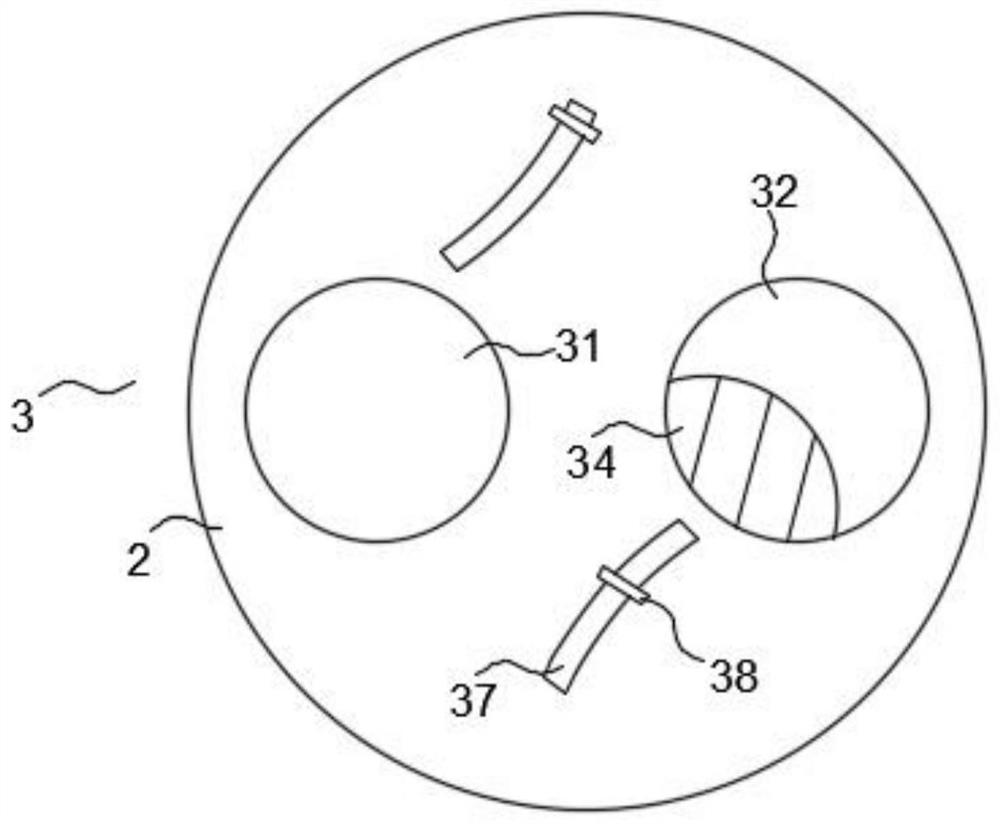

[0040] Such as Figure 1-6 As shown, the present invention proposes an arm-type water pump with a telescopic bending structure, including a water pump main body 1, the left outer surface of the water pump main body 1 is fixedly connected with a connection end 2, and the right side of the connection end 2 is provided with a The opening 21, the left outer surface of the connection end 2 is provided with a separate pumping mechanism 3;

[0041] The sub-drawing mechanism 3 includes a first interface 31, a second interface 32, an arc groove 33, a closed plate 34, a fixing piece 35, a fixed groove 36 and a movable groove 39, and the first interface 31 and the second interface 32 are all set on the connecting end On the left outer surface of 2, two through-pipes can be connected at the same time by using two interfaces, so that they can be replaced and used, which improves the working efficiency of the device. The inside of the connecting end 2 is located at the rear end of the secon...

Embodiment 2

[0046] Such as Figure 7-11 As shown, the left outer surfaces of the first interface 31 and the second interface 32 are provided with telescopic mechanisms 4;

[0047] Telescoping mechanism 4 comprises first through pipe 41, second chute 42, second through pipe 43, first slide block 44, thread groove 45, threaded rod 46, the 3rd chute 47, the 3rd through pipe 493, the second Slider 494 and draw-in groove 495, the inner inner wall of the first through pipe 41 is provided with the second chute 42, is used for the second through pipe 43 can effectively move inside the first through pipe 41, the inside of the first through pipe 41 A second through pipe 43 is movably connected, and the outer surface of the second through pipe 43 is fixedly connected with a first slider 44 near the right side, which can effectively slide inside the first chute 37, so that the second through pipe 43 is The inside of the first through pipe 41 moves conveniently and simultaneously acts as a limiter to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com