Well site calibration device of while-drilling neutron porosity logger and using method

A technology of neutron porosity and verification device, which is applied in wellbore/well components, measurement, earth-moving drilling, etc., and can solve the problem of inability to detect radioactive working conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

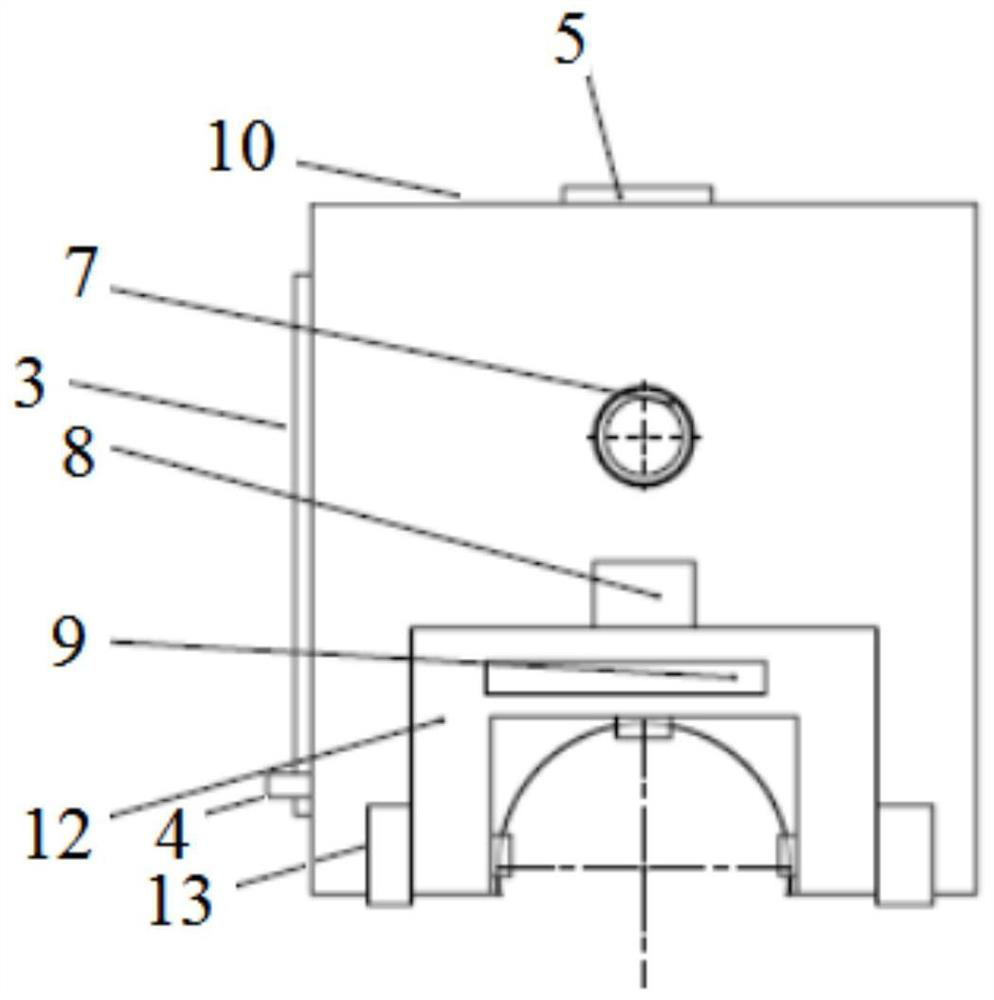

[0033] The technical solutions are clearly and completely described below in conjunction with the accompanying drawings of the present invention. Apparently, the described embodiments are part of the embodiments of the present invention, but not all of them.

[0034] The present invention is a well site verification device of a neutron porosity logging tool while drilling, such as Figure 7 As shown, it includes a first support 1, a liquid level gauge 3, a level 5, a second support 12 and a box body; the box body is a cuboid with a hollow structure, and the box body is used to hold water, and the box body is provided with an upper cover 10 and a bottom cover 11. The end face of the bottom cover 11 is concavely set, and the bottom cover 11 is lapped on the outer diameter of the neutron porosity logging tool 2 while drilling and covers the detection area of the neutron porosity logging tool 2 while drilling. The distance between the top of the neutron porosity logging tool 2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com