A kind of bubble glaze for glass mosaic and preparation process of glass mosaic

A technology of glass mosaic and bubble glaze, which is applied in the field of glass mosaic, can solve the problem of single surface effect, etc., and achieve the effect of strong three-dimensional effect, good bubble effect and clear texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

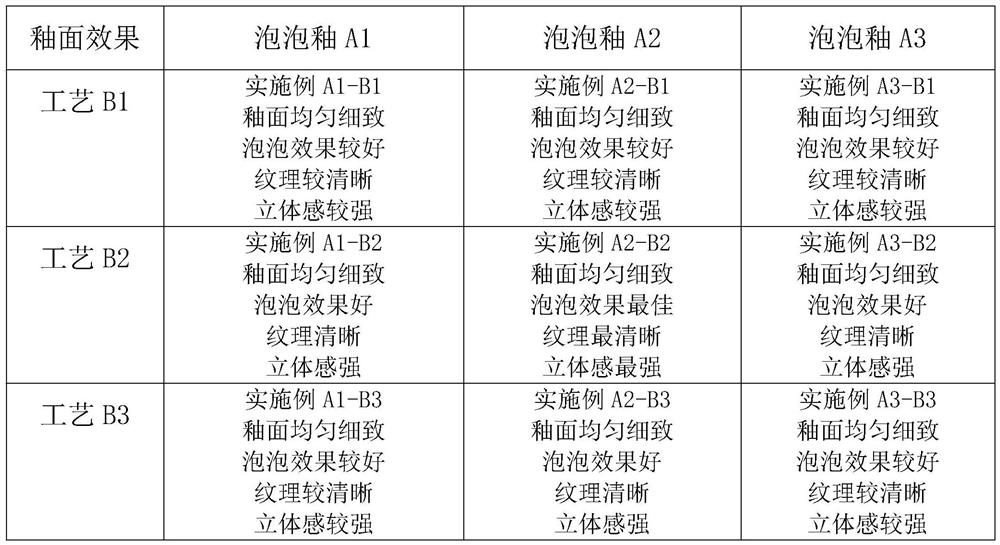

[0051] Embodiment group A-B-a kind of preparation technology of the glass mosaic with bubble effect, comprises the following steps:

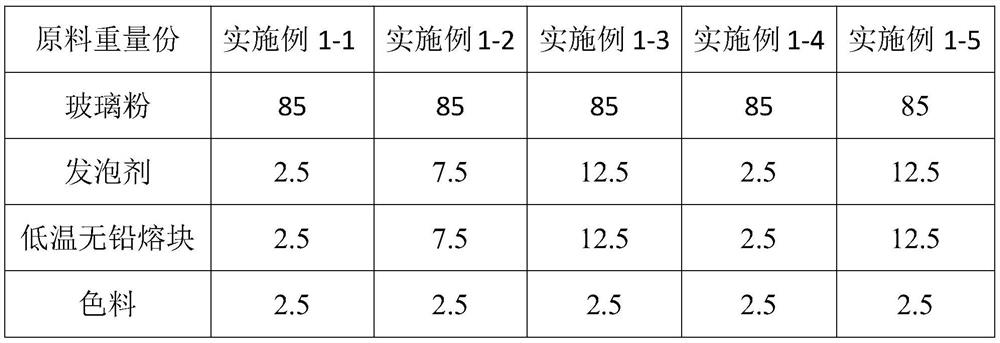

[0052] (1) Weigh the glass powder, blowing agent and low-temperature lead-free frit according to the proportions in Table 1 below, and sieve them to the limits of the glaze fineness in Table 2 below, and set aside;

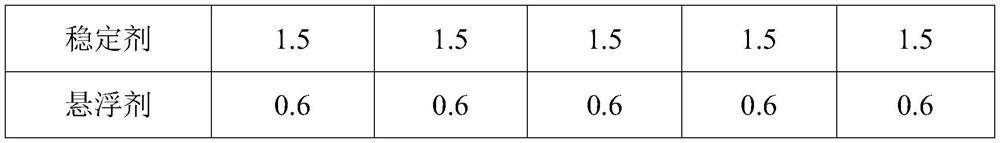

[0053] (2) Take the sieved glass powder, foaming agent and low-temperature lead-free frit, add stabilizer and suspending agent, add water and carry out ball milling, the ball milling process parameters are limited by the ball milling ratio and ball milling time in Table 2, and obtain the basic glaze pulp;

[0054] (3) Take 90-95 parts of the basic glaze slurry obtained in step (2), and 0-5 parts of the coloring material, stir evenly, add water to mix according to the mass-volume concentration limit in Table 2, and obtain the glazing glaze slurry-bubble Glaze A1, A2, A3;

[0055] (4) Apply the glazing slurry obtained in step (3) to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com