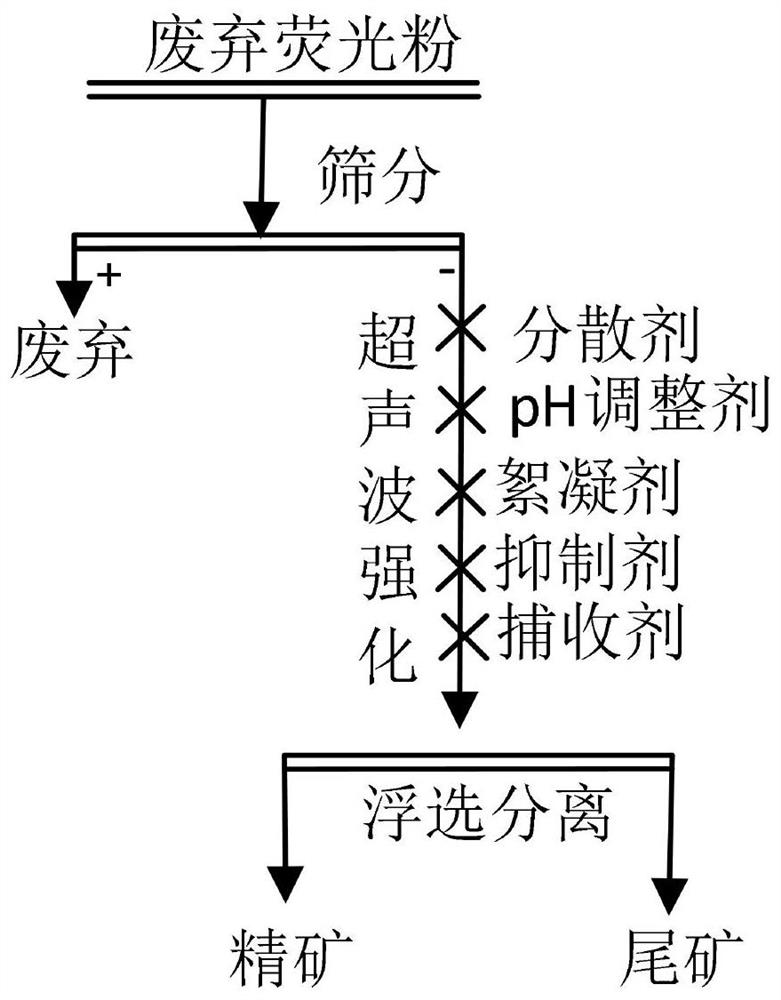

Method for recovering rare earth elements in waste fluorescent powder through ultrasonic enhanced flotation

A rare earth element and phosphor technology, used in flotation, process efficiency improvement, solid separation, etc., can solve the problems of complex waste phosphor composition, low sorting recovery rate, poor sorting effect, etc., to improve flotation effect, reduce environmental harm, improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The waste fluorescent powder recovered from a fluorescent lamp manufacturing enterprise in Zhejiang Province was obtained. Laboratory analysis showed that the rare earth oxide grade was 18.82%, that is, the rare earth oxide content was 18.82%.

[0027] (1) Add 20mL of 0.1mol / L sodium carbonate solution into a 100mL flotation cell, and turn on the ultrasonic device to perform ultrasonic treatment on the sodium carbonate solution.

[0028] (2) Pass the above-mentioned waste fluorescent powder through a 200-mesh sieve to remove large particles of impurities and organic flocs, weigh 10 g of the waste fluorescent powder after sieving and place it in the sodium carbonate solution for ultrasonic treatment in step (1), add water To the scale line of the flotation cell, it is configured as an ore slurry with a mass fraction of phosphor powder of 10%;

[0029] (3) adding sodium carbonate to the pulp to regulate the pH value of the pulp is 9, and ultrasonic treatment is carried ou...

Embodiment 2

[0037] It was taken from unqualified waste powder produced in the production process of a fluorescent lamp manufacturer. Laboratory analysis showed that the rare earth oxide grade was 22.73%.

[0038] (1) Take 20mL of 0.1mol / L sodium silicate solution and add it to a 100mL flotation cell, and turn on the ultrasonic device to perform ultrasonic treatment on the sodium silicate solution.

[0039] (2) Pass the above-mentioned waste fluorescent powder through a 200-mesh sieve to remove large particles of impurities and organic flocs, weigh 15g of the waste fluorescent powder after sieving and place it in the sodium silicate solution for ultrasonic treatment in step (1), Add water to the scale line of the flotation tank, and configure it as a slurry with a mass fraction of phosphor powder of 15%;

[0040] (3) adding sodium carbonate to the pulp to regulate the pH value of the pulp is 10, and ultrasonic treatment is carried out;

[0041] (4) Continue to add 5mL of 5% aluminum chlor...

Embodiment 3

[0048] It was taken from the unqualified waste powder produced by a fluorescent material company in the process of phosphor powder preparation. Laboratory analysis showed that the rare earth oxide grade was 45.10%.

[0049] (1) Add 30 mL of 0.1 mol / L sodium hexametaphosphate solution into a 100 mL flotation cell, and turn on the ultrasonic device to perform ultrasonic treatment on the sodium hexametaphosphate solution.

[0050] (2) Pass the above-mentioned waste fluorescent powder through a 200-mesh sieve to remove large particles of impurities and organic flocs, weigh 5g of the waste fluorescent powder after sieving and place it in the sodium hexametaphosphate solution for ultrasonic treatment in step (1) , add water to the scale line of the flotation cell, and configure it as an ore slurry with a phosphor mass fraction of 5%;

[0051] (3) adding sodium hydroxide to the pulp to adjust the pH value of the pulp to be 8, and carry out ultrasonic treatment;

[0052](4) Continue ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com