A compound emulsifier

A compound emulsifier, monoglyceride monoglyceride technology, applied in baking, food science, application and other directions, can solve the problems of easy betaization of monoglycerides, instability of cake oil, etc., and achieve good bubble performance and good stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

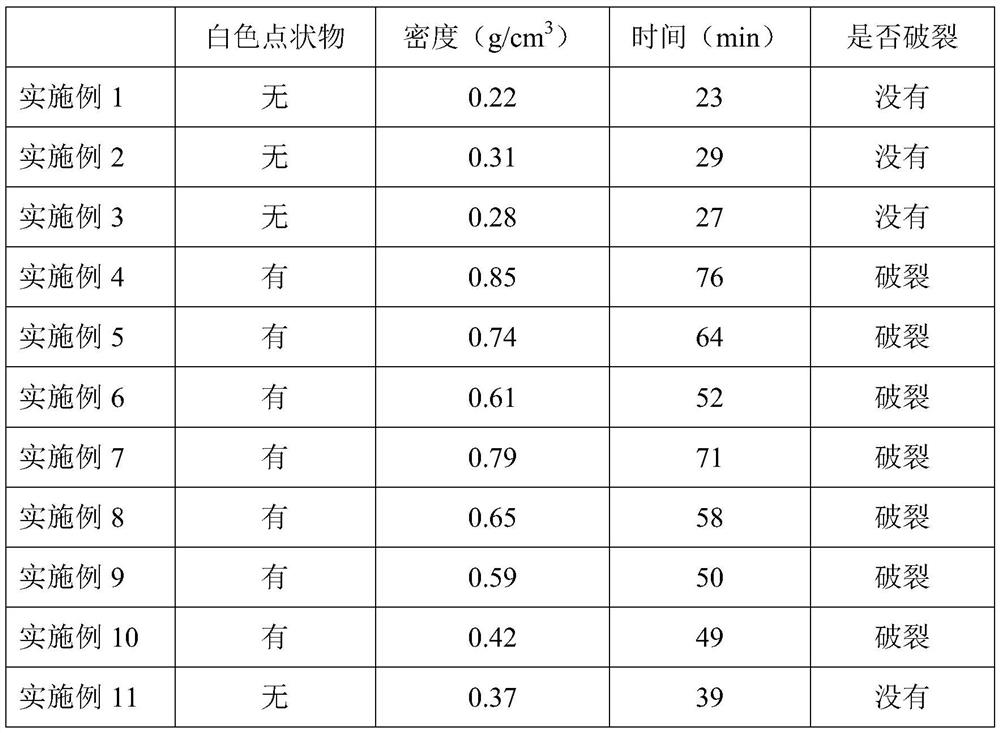

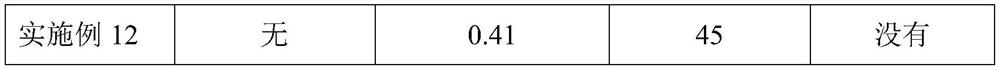

Examples

preparation example Construction

[0049] In one embodiment, the preparation method of the composite emulsifier comprises: pretreated monoglycerides of fatty acids, glycerides of difatty acids, Span, Tween, sorbitol solution and water at 73-76 Mix evenly at ℃; then add alkaline substances, sucrose esters and low-molecular sugars in parts by weight, mix evenly at 65-68°C, and then cool to room temperature.

[0050] Preferably, the preparation method of described composite emulsifier is:

[0051] (1) Pretreatment process of monoglycerides of fatty acids: mix long-chain monoglycerides, short-chain monoglycerides, and dodecyl tetramethylguanidine with water, and slowly heat to 68-70°C until a uniform The dispersion is then cooled to room temperature, and the pH is adjusted to 7.5 to form a gel;

[0052] (2) Mix the pretreated monoglycerides, diglycerides, Span, Tween, sorbitol solution and water at 73-76°C by parts by weight; then add part by part of alkaline The substances, sucrose esters and low-molecular sugar...

Embodiment 1

[0056] Embodiment 1 of the present invention provides a composite emulsifier, in parts by weight, its preparation raw materials include 16 parts of glycerin derivatives, 30 parts of sorbitol substances, 30 parts of water, 0.65 parts of alkaline substances, 2 parts of sucrose esters and 1 part of Parts of low molecular carbohydrates;

[0057] The glycerol derivatives include mono- and diglyceride fatty acid esters and polyglycerol fatty acid esters; the mono- and diglyceride fatty acid esters include monoglycerides and diglycerides;

[0058] The weight ratio of the mono- and diglycerin fatty acid ester to the polyglycerol fatty acid ester is 1:0.5;

[0059] The monoglycerides include long-chain monoglycerides and short-chain monoglycerides;

[0060] The weight ratio of the long-chain monoglycerides to short-chain monoglycerides is 11:4;

[0061] The carbon number of the long-chain monoglyceride is 12; the carbon number of the short-chain monoglyceride is 9;

[0062] The poly...

Embodiment 2

[0075] Embodiment 2 of the present invention provides a kind of compound emulsifier, and its specific implementation mode is the same as embodiment 1, and difference is:

[0076] Its preparation raw materials include 8 parts of glycerin derivatives, 15 parts of sorbitol substances, 15 parts of water, 0.01 parts of alkaline substances, 0.01 parts of sucrose esters and 0.2 parts of low-molecular sugar substances;

[0077] The weight ratio of the long-chain monoglycerides to short-chain monoglycerides is 10:3;

[0078] The number of carbon atoms of the long-chain monoglyceride of fatty acid is 11; the number of carbon atoms of the short-chain monoglyceride of fatty acid is 7;

[0079] The weight ratio of the long-chain monoglycerides, short-chain monoglycerides, dodecyl tetramethylguanidine to water is 10:3:0.:86.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com