Combination processing method of catalytic cracking oil slurry

A catalytic cracking oil slurry and combined processing technology, which is applied in the petroleum industry, hydrotreating process, hydrocarbon oil treatment, etc., can solve the problems of low comprehensive utilization rate of oil slurry resources with high added value and unclean removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

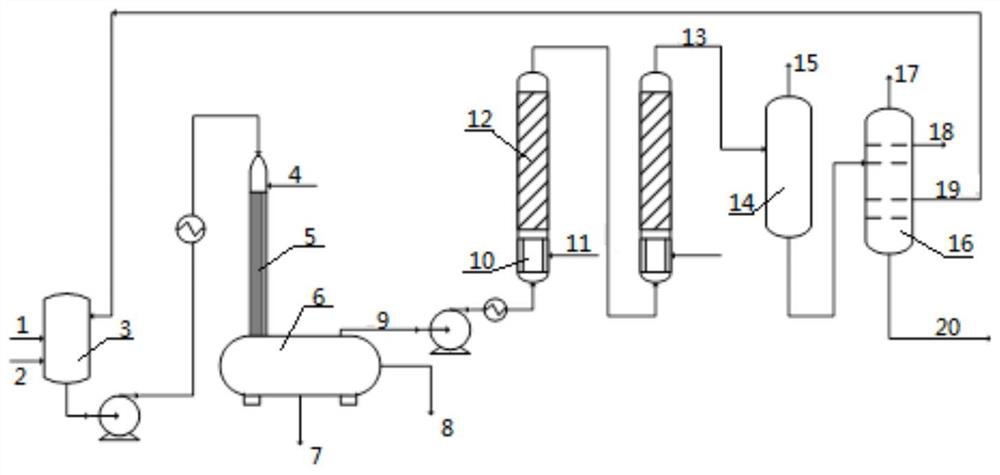

Method used

Image

Examples

Embodiment approach

[0046] According to a preferred embodiment of the present invention, the diluted oil slurry is preheated and then mixed with water. Preheating the diluted oil slurry can further completely dissolve the oil slurry in the diluent, thereby improving the desolidification effect of the diluted oil slurry and water. The preheating temperature is preferably 50-150°C, preferably 60-100°C.

[0047] In the present invention, the fiber filaments have good hydrophilicity and can simultaneously capture the inclusions formed by the amphoteric surface activity and the catalyst powder as well as water, so as to fully realize the desolidification of the catalytic cracking oil slurry.

[0048] Specifically, the amphoteric surfactant of the present invention has positive and negative charges at the same time, and has an isoelectric point. When the amphoteric surfactant is dispersed on the fiber filament with water, the electron-rich colloid and asphalt in the oil phase The catalyst powder is no...

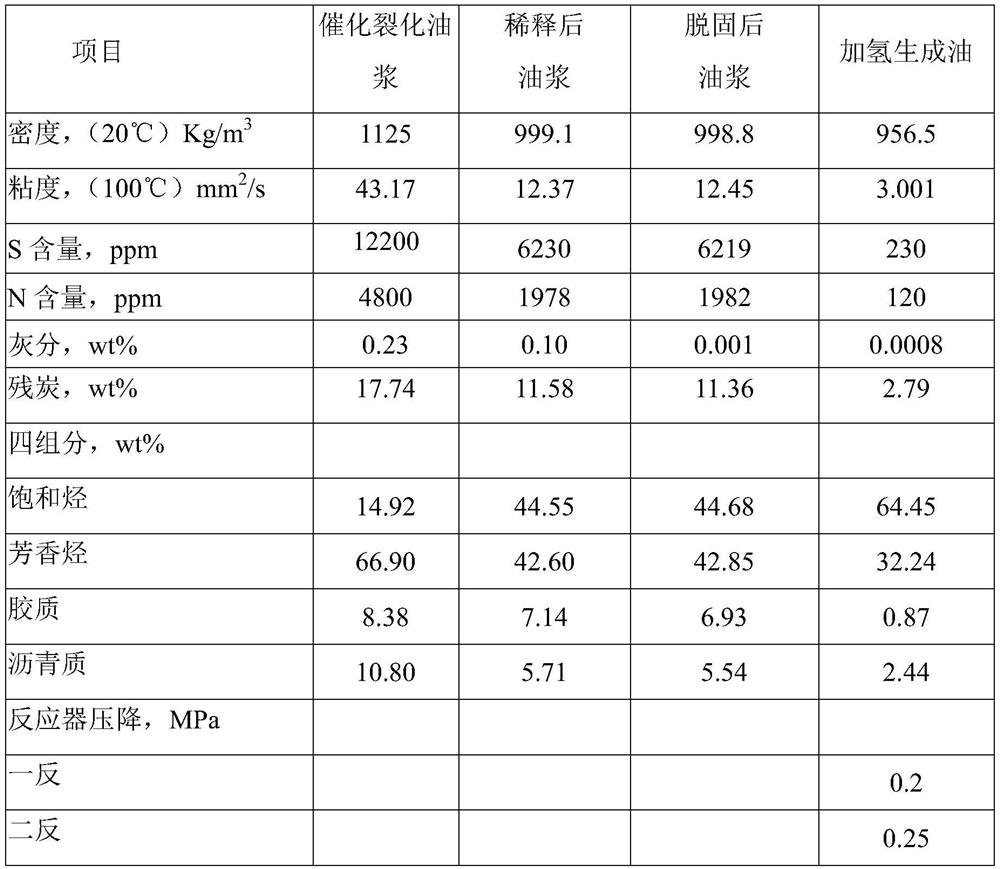

Embodiment 1

[0077] (1) Combine 1# catalytic cracking oil slurry (the composition is shown in Table 1), sodium lauryl iminodipropionate and diluent (atmospheric pressure diesel oil and ethyl acetate volume ratio is 5:1, density is 0.86g / cm 3 ) according to the mass ratio of 1:0.0001:1.5 after mixing and diluting, preheat to 100 ℃. The fiber filaments in the mass transfer space cylinder of the fiber liquid film contactor are 316 series stainless steel wires (0.05mm in diameter), the aspect ratio of the mass transfer space of the cylinder is 60:1, and the filling rate of the cylinder is 5 % by volume, the volume of the fiber liquid membrane contactor is 0.3L. The volumetric space velocity of the preheated diluted oil slurry is 20h -1 Inject into the fiber liquid film contactor, and at the same time inject 10% by weight (relative to the diluted oil slurry) into the fiber liquid film contactor; the contact temperature in the fiber liquid film contactor is 130° C., and the contact pressure is ...

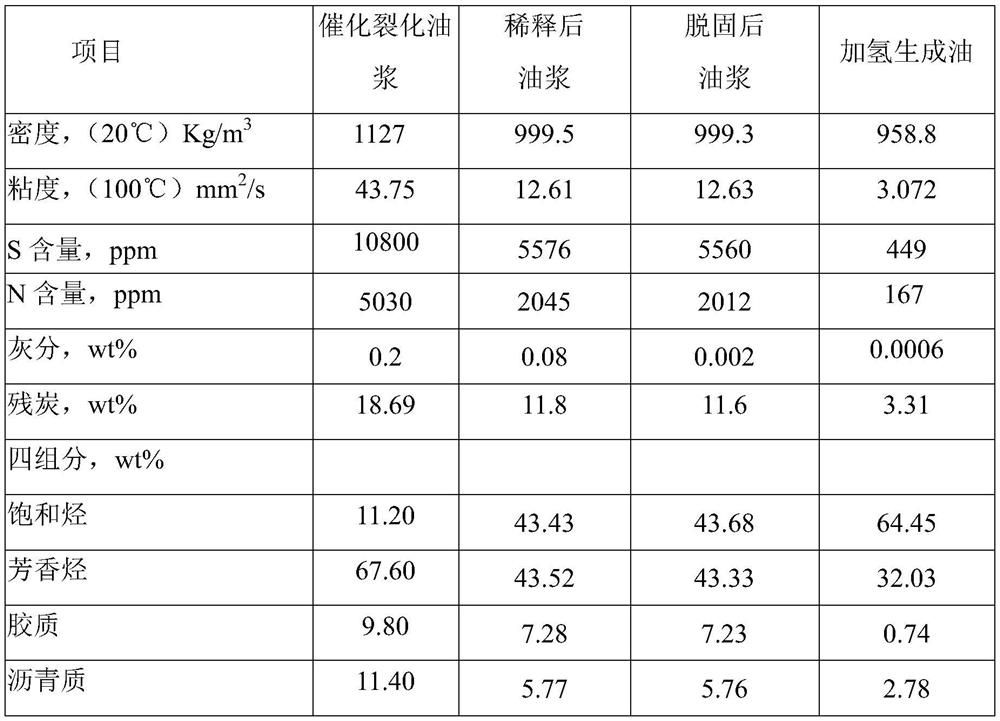

Embodiment 2

[0085] (1) Combine 2# catalytic cracking oil slurry (the composition is shown in Table 2), lauryl betaine and diluent (the volume ratio of coked diesel oil and ethyl laurate is 10:1, and the density is 0.862g / cm 3 ) according to the mass ratio of 1:0.0003:0.5 after mixing and diluting, preheat to 50 ℃. The fiber filaments in the mass transfer space cylinder of the fiber liquid film contactor are 316 series stainless steel wires (0.05mm in diameter), the aspect ratio of the mass transfer space of the cylinder is 10:1, and the filling ratio of the cylinder is 30 % by volume, the volume of the fiber liquid membrane contactor is 0.3L. Dilute the preheated oil slurry according to the liquid hour volume space velocity of 10h -1 Inject into the fiber liquid film contactor, and at the same time inject 10% by weight (relative to the diluted oil slurry) into the fiber liquid film contactor; the contact temperature in the fiber liquid film contactor is 150° C., and the contact pressure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com