Method for continuously reducing ingot by germanium dioxide

A germanium dioxide and ingot casting technology is applied in the field of germanium dioxide continuous reduction ingot casting, which can solve the problems of long time required for reduction ingot casting, low production efficiency, and inability to release production capacity, and shorten the reduction ingot casting time and labor intensity. Small, the effect of promoting a sufficient reduction reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

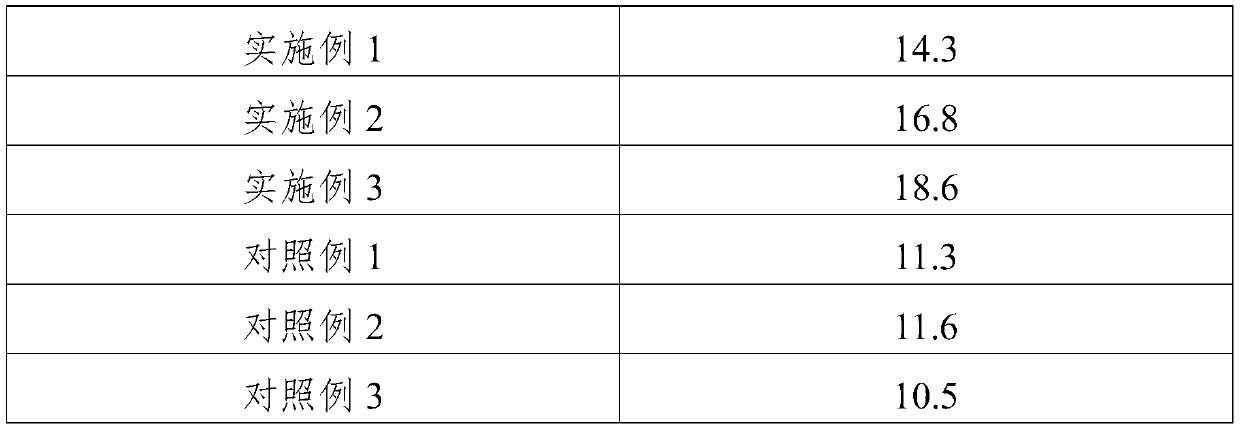

Embodiment 1

[0018] The embodiment of the present invention is a method for continuously reducing ingot casting with germanium dioxide, and the method comprises the following steps:

[0019] The germanium dioxide is loaded into the graphite boat and placed in the furnace, wherein the amount of germanium dioxide loaded into the boat is 70% of the capacity of the graphite boat. Under the hydrogen atmosphere, the graphite boat loaded with germanium dioxide is heated through seven heating temperature zone, the temperatures of the seven heating temperature zones are respectively: 200°C, 400°C, 500°C, 600°C, 700°C, 800°C, 1000°C; the graphite boat loaded with germanium dioxide is in the seven temperature zones The intermediate residence time is respectively 30min; then, the germanium ingot is obtained by cooling down.

Embodiment 2

[0021] The embodiment of the present invention is a method for continuously reducing ingot casting with germanium dioxide, and the method comprises the following steps:

[0022] Put germanium dioxide into a graphite boat and put it into the furnace, wherein the amount of germanium dioxide loaded into the boat is 90% of the capacity of the graphite boat. Under a hydrogen atmosphere, the graphite boat loaded with germanium dioxide is heated through seven heating temperature zone, the temperatures of the seven heating temperature zones are respectively: 400°C, 500°C, 600°C, 700°C, 900°C, 1000°C, 900°C; the graphite boat loaded with germanium dioxide is in the seven temperature zones The intermediate residence time is respectively 60min; then, the germanium ingot is obtained by cooling down.

Embodiment 3

[0024] The embodiment of the present invention is a method for continuously reducing ingot casting with germanium dioxide, and the method comprises the following steps:

[0025] Put germanium dioxide into a graphite boat and put it into the furnace, wherein the amount of germanium dioxide loaded into the boat is 80% of the capacity of the graphite boat. Under a hydrogen atmosphere, the graphite boat loaded with germanium dioxide is heated through seven heating temperature zone, the temperatures of the seven heating temperature zones are respectively: 200°C, 450°C, 600°C, 650°C, 750°C, 900°C, 1000°C; the graphite boat loaded with germanium dioxide is in the seven temperature zones The intermediate residence time is respectively 40min; then, the germanium ingot is obtained by cooling down.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com