Multi-station automatic bobbin case replacing system and method

A multi-station, bobbin case technology, applied in the mechanism of embroidery machines, embroidery machines, textiles and papermaking, etc., can solve the problems of small space, reduced production efficiency, large labor input, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

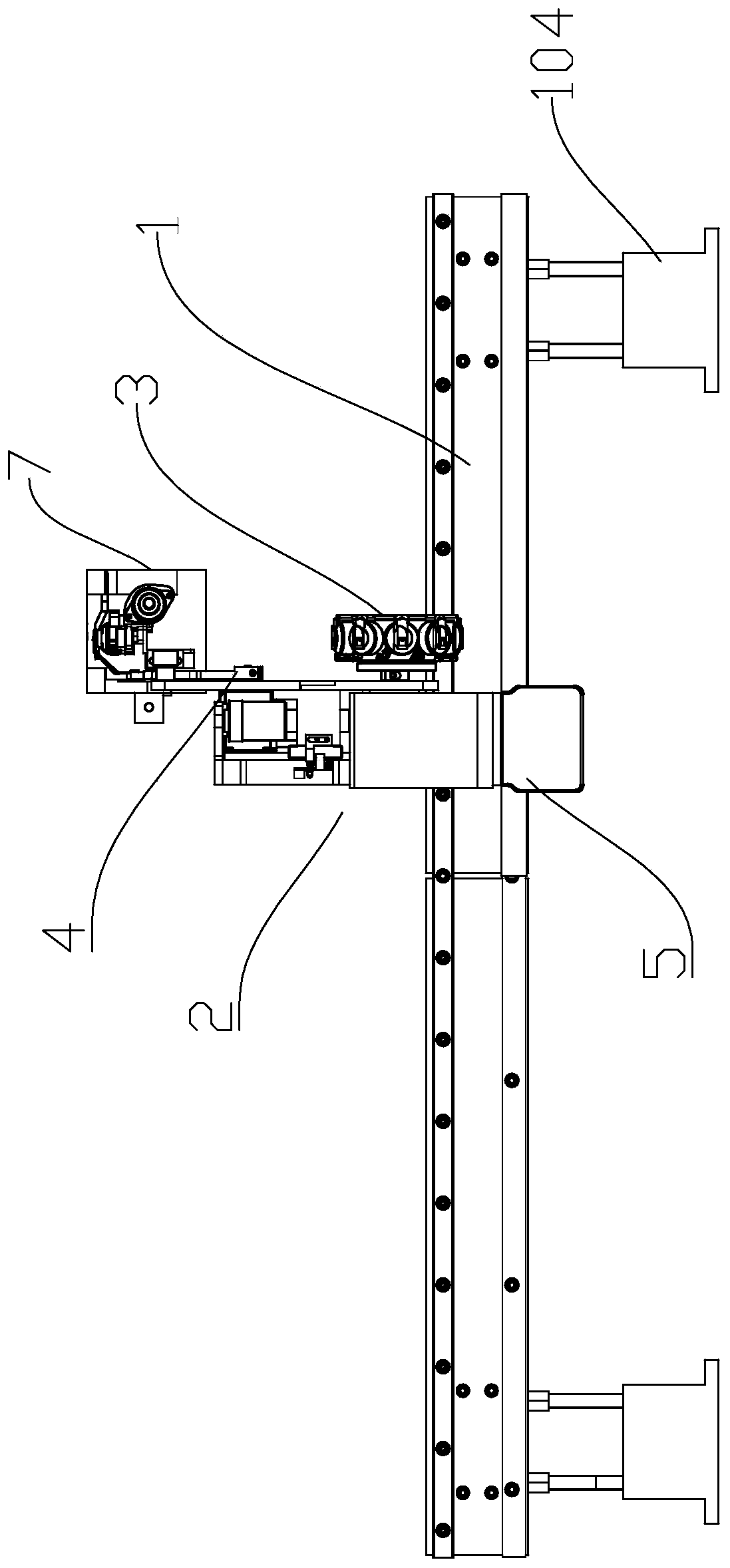

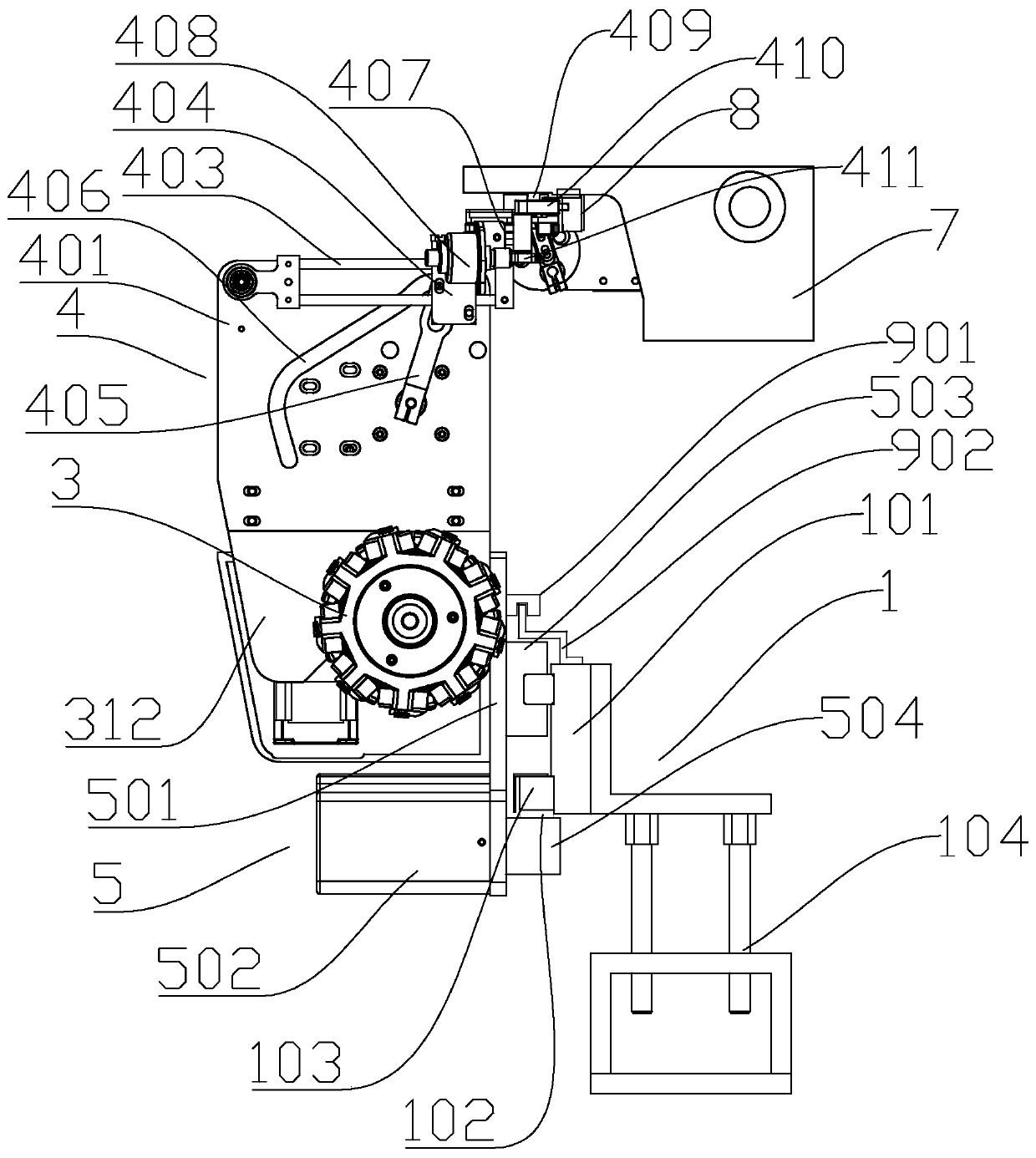

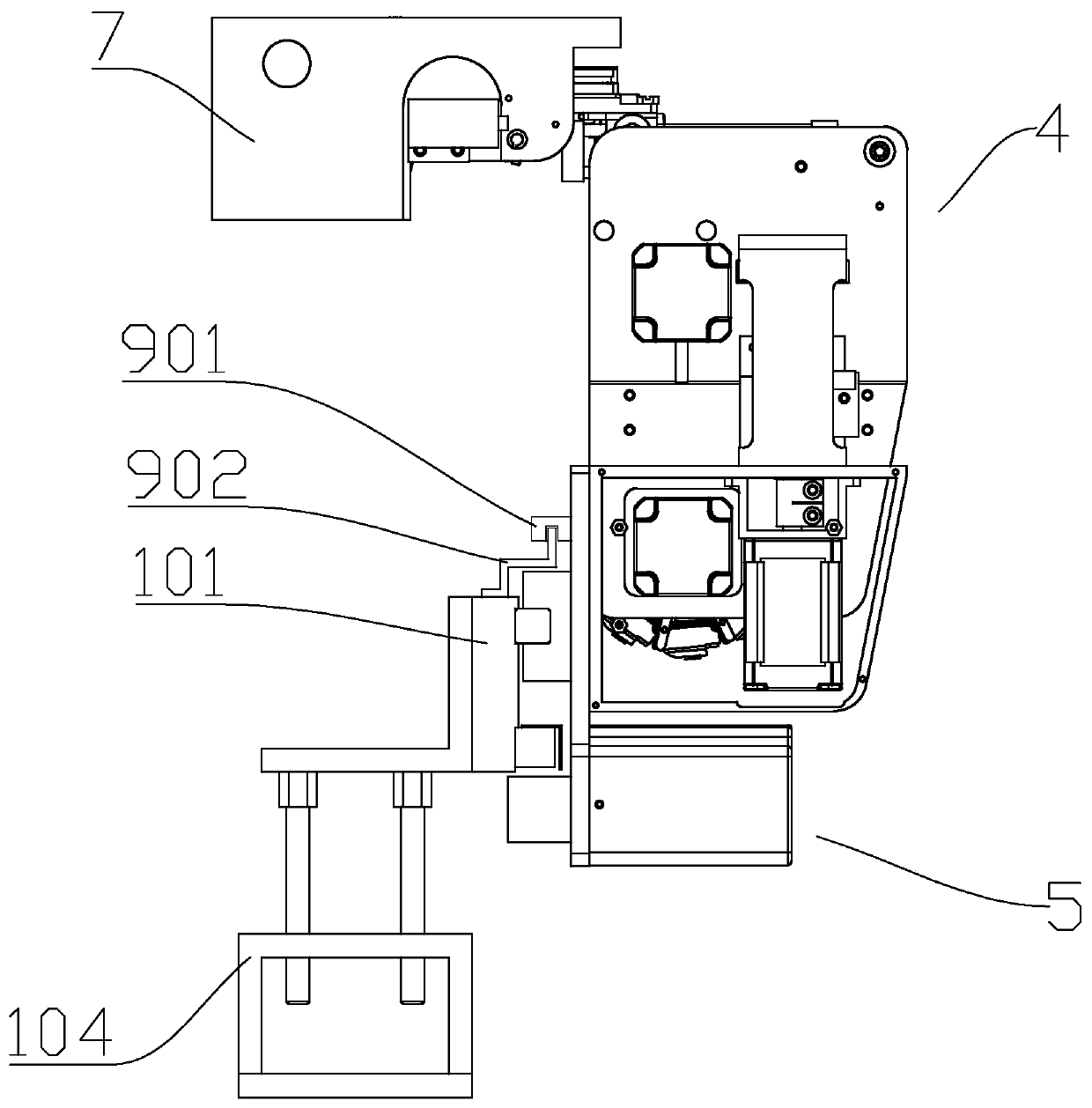

[0049] Such as figure 1 , figure 2 , image 3 As shown, the embodiment of the present invention provides a multi-station automatic bobbin case changing system, which includes a horizontal guide mechanism 1 and a bobbin case replacement device 2. The horizontal guide mechanism 1 is arranged under the shuttle box of the embroidery machine and guides Mechanism 1 extends along the line direction of each shuttle box body, and the bobbin case replacement device 2 includes a bobbin case grasping part 4, a bobbin case storage part and a translation drive part 5, and the translation drive part 5 slides with the horizontal guide mechanism 1 Connected and capable of translating and sliding along the horizontal guide mechanism 1, the bobbin case storage part includes a detachable and rotatably connected storage turntable 3, and several bobbin case storage stations are set around the storage turntable 3.

[0050] Such as figure 2 , Figure 4 , Figure 7 As shown, the bobbin case gra...

Embodiment 2

[0090] The biggest difference between this embodiment and the above-mentioned embodiment 1 is:

[0091] The driving mechanism that drives the translational driving part 5 to translate and slide along the horizontal guide rail 101 is replaced by a rack and pinion mechanism with a screw translation mechanism. The specific structure of the screw translation mechanism is common knowledge in the prior art in the art, and will not be repeated here.

[0092] The screw translation mechanism has the characteristics of accurate and stable positioning and good guiding performance. The application in this embodiment can ensure that the translation driving part 5 can stably translate and slide along the horizontal guide rail 101, and realize precise positioning according to work requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com