Comprehensive pipe gallery tunnel with multiple parallel compartments mutually independent in structure and construction method of comprehensive pipe gallery tunnel

An independent and integrated pipe gallery technology, applied in tunnels, earth-moving drilling, mining equipment, etc., can solve the problem of eccentric load on the shared side wall, unfavorable structural stability of the shared side wall, and unfavorable stress on the shared side wall. problem, to achieve the effect of simple stress conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Specific embodiments of the present invention will be described in detail below for further understanding of the present invention.

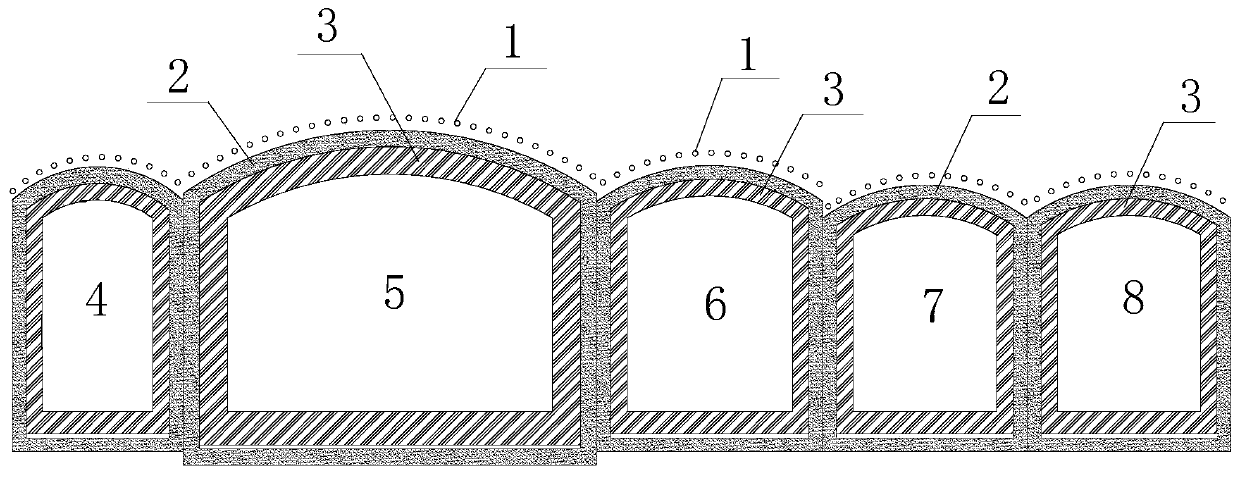

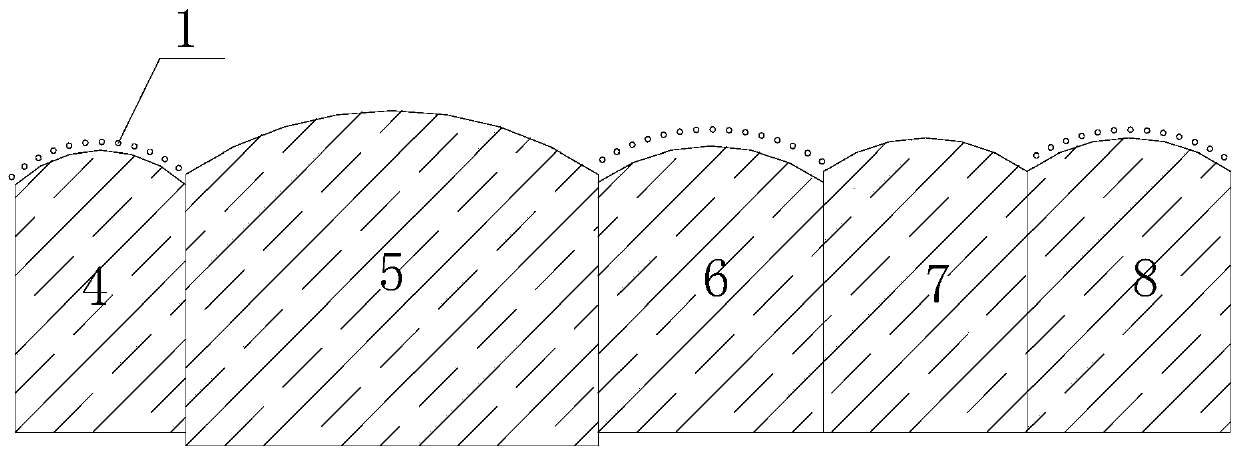

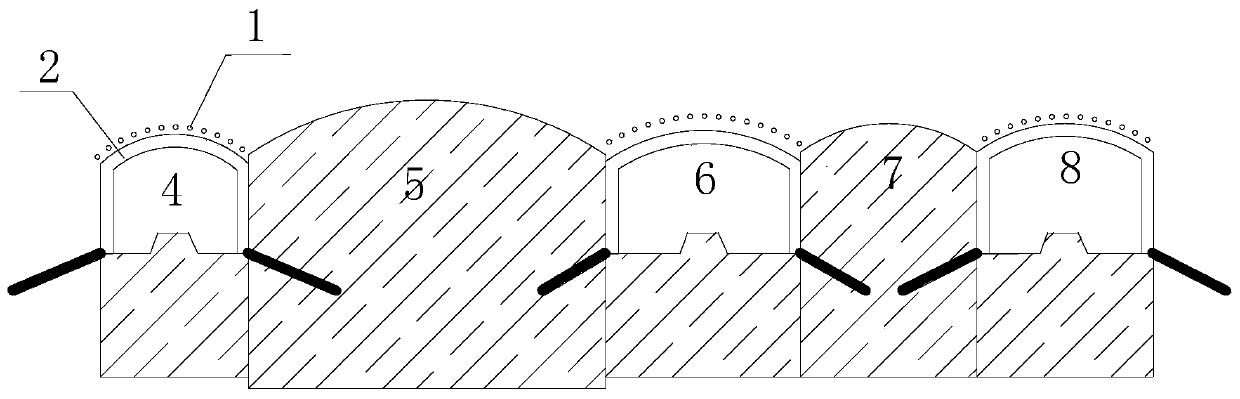

[0041] figure 1 It is a schematic diagram of a multi-chamber parallel comprehensive pipe gallery tunnel with independent structures of the present invention. Such as figure 1 Shown:

[0042] A multi-chamber side-by-side comprehensive pipe corridor tunnel with independent structures, which is composed of multiple independent cabins, each cabin of independent structure includes an advance support structure 1, an initial support structure 2 and a secondary lining structure 3, the initial support structure The protection structure 2 is a surrounding structure, the advanced support structure 1 is arranged above the primary support structure 2, and the secondary lining structure 3 is arranged around the inner surface of the primary support structure.

[0043] The advance support structure 1 includes an advance grouting layer and an advance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com