An electrical pyrotechnics component

A technology of electric explosive products and components, which is applied in the direction of weapon accessories, blasting barrels, offensive equipment, etc., can solve the problems of high ignition energy, high ignition voltage, and reduce the ability of electric explosive products to resist static electricity and electromagnetic interference, etc. The effect of simple conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

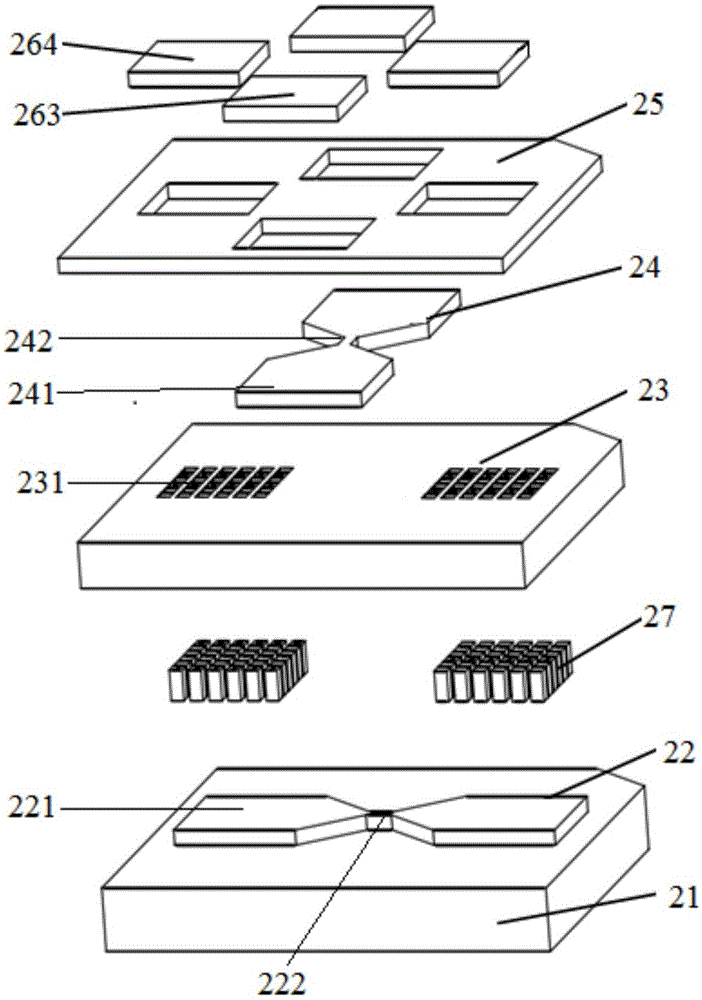

[0030] like figure 1 As shown, the electronic switch of the high-safety and low-energy-consumption electric explosive component includes: an electronic switch substrate 21, a control bridge 22, an insulating layer 23, a wire bridge 24, a passivation layer 25, a metal interconnection 27, and a pair of control bridge electrodes Pads 264 and a pair of wire bridge electrode pads 263; wherein, the control bridge 22 is formed on the substrate 21, including a pair of control bridge electrodes 221, and a control bridge bridge region 222 connecting the two; the insulating layer 23 covers the control bridge On the bridge 22; on the insulating layer 23, a plurality of through holes 231 are arranged at the position facing the pair of control bridge electrodes 221 of the control bridge 22, forming a through hole array; the wire bridge 24 is formed on the insulating layer 23, including a pair of wires Bridge electrode 241, and the wire bridge bridge area 242 that connects the two; The cont...

Embodiment 2

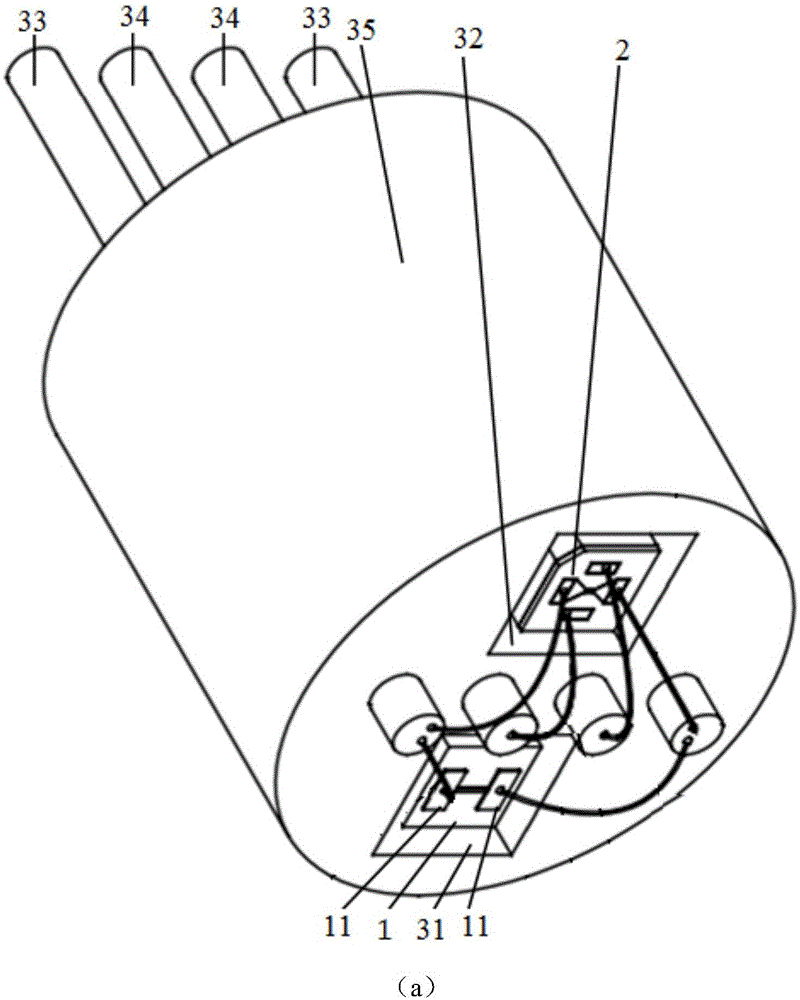

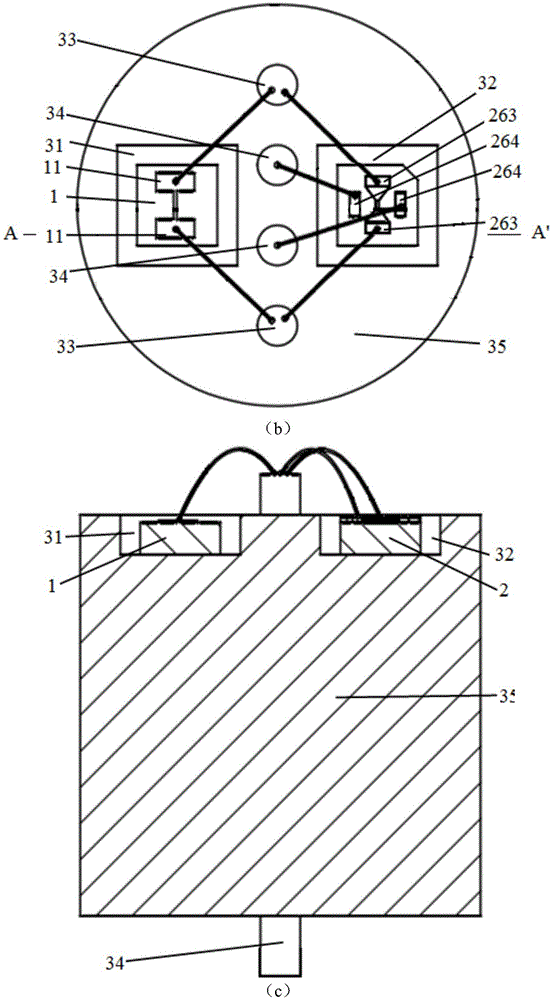

[0034] In this embodiment, the electronic switch 2 is packaged in the packaging structure 28, and the packaging structure includes a through hole, a pair of packaging structure control pads 284 and a pair of packaging structure wire pads 283; the upper surface of the packaging structure 28 is provided with a through hole , the through hole is facing the area where the electric explosion occurs in the electronic switch, and a pair of packaging structure control pads 284 and a pair of packaging structure wire pads 283 are exposed on the lower surface of the packaging structure 28, and a pair of control bridge electrodes of the electronic switch are soldered The pads 264 are respectively connected to a pair of packaging structure control pads 284 by wire bonding; the pair of wire bridge electrode pads 263 of the electronic switch are respectively connected to a pair of packaging structure wire pads 283 by wire bonding. The package structure 28 with the electronic switch 2 packaged...

Embodiment 3

[0036] In this embodiment, the package body adopts the substrate 4, and the substrate adopts a printed circuit board PCB substrate, or a ceramic substrate. Parallel connection of switches and electrical explosives. like Figure 4 As shown, the substrate includes a base, a pair of ignition circuit pads and a pair of safety circuit pads; wherein, the two ignition electrodes 11 of the electrical pyrotechnic device 1 are respectively connected to a pair of ignition circuit pads 43 of the substrate; the electronic switch A pair of wire bridge electrode pads 263 of 2 are respectively connected to a pair of ignition circuit pads 43 of the substrate to realize the parallel connection of electronic switch 2 and electrical pyrotechnic device 1, and a pair of ignition circuit pads 43 are respectively connected through metal wiring 46. To the external ignition control circuit of electrical pyrotechnics; a pair of control bridge electrode pads 264 of the electronic switch 2 are respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com