an air motor

An air motor and air hole technology, applied in the direction of engine components, machines/engines, engine sealing devices, etc., can solve problems such as unstable output torque, failure to start, unstable speed, etc., to achieve stable output torque and speed, and working conditions Simple, smooth rotating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

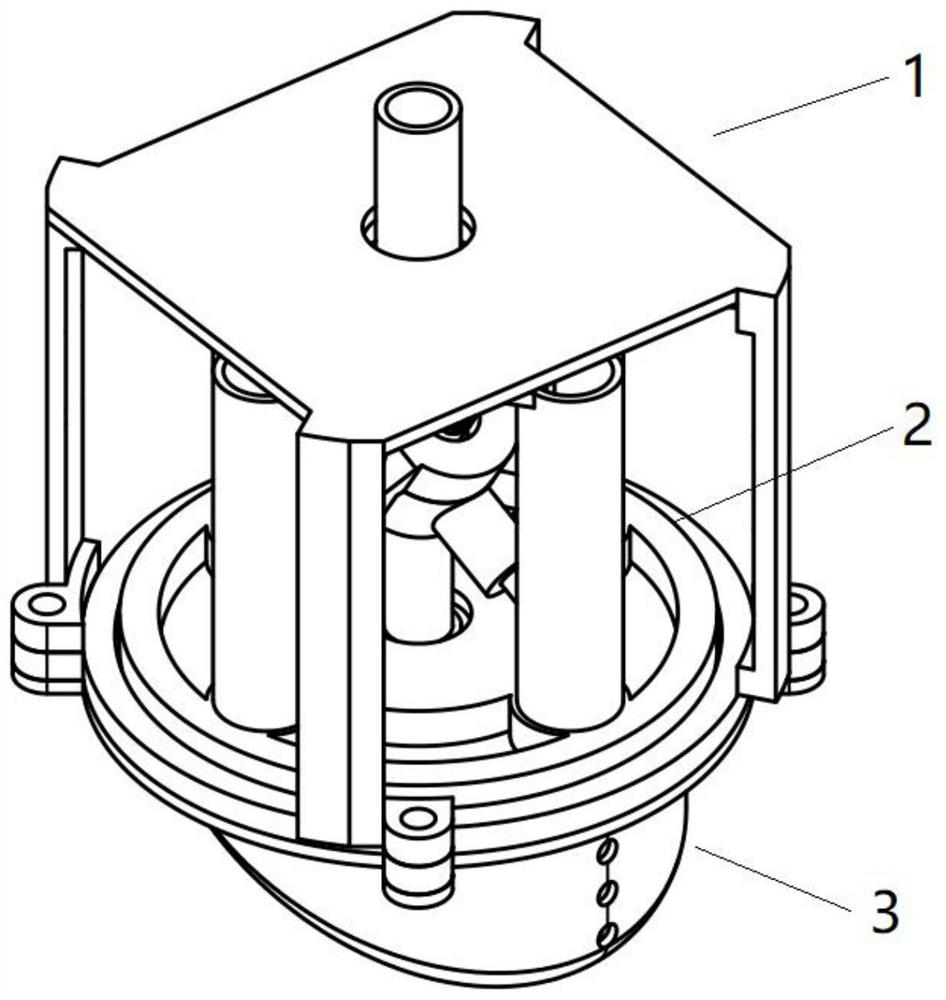

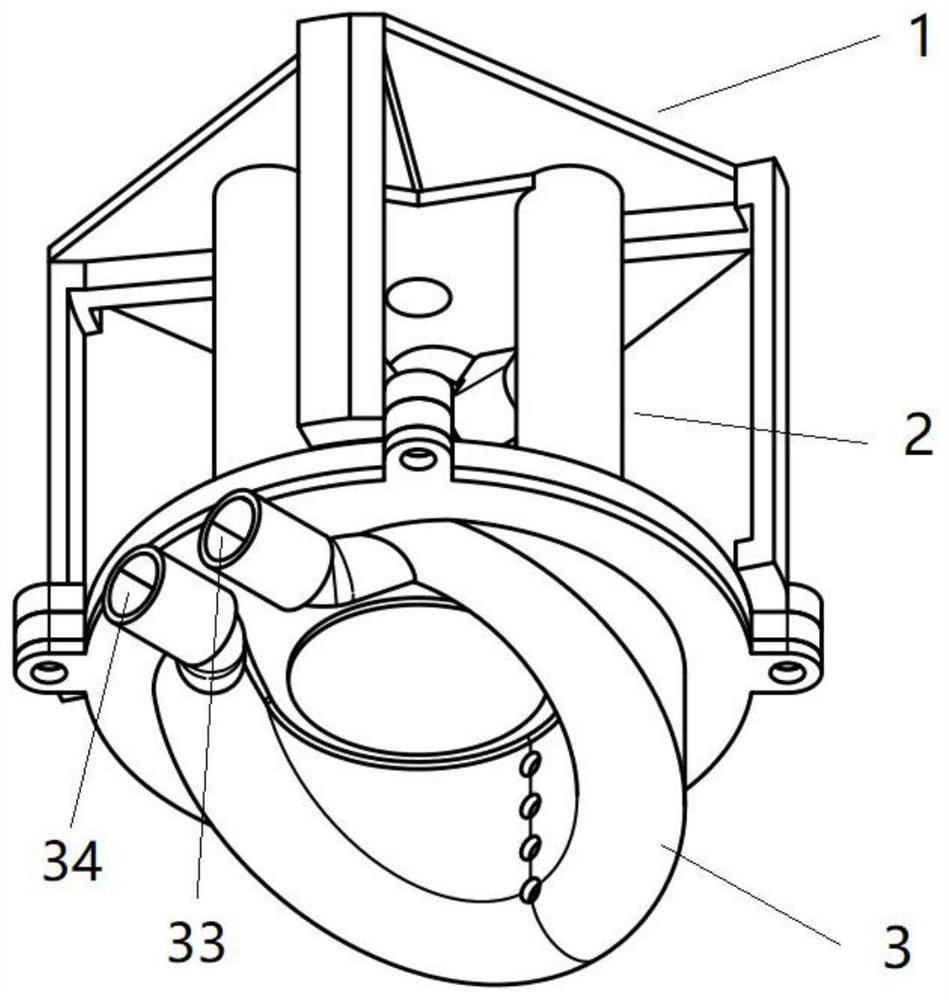

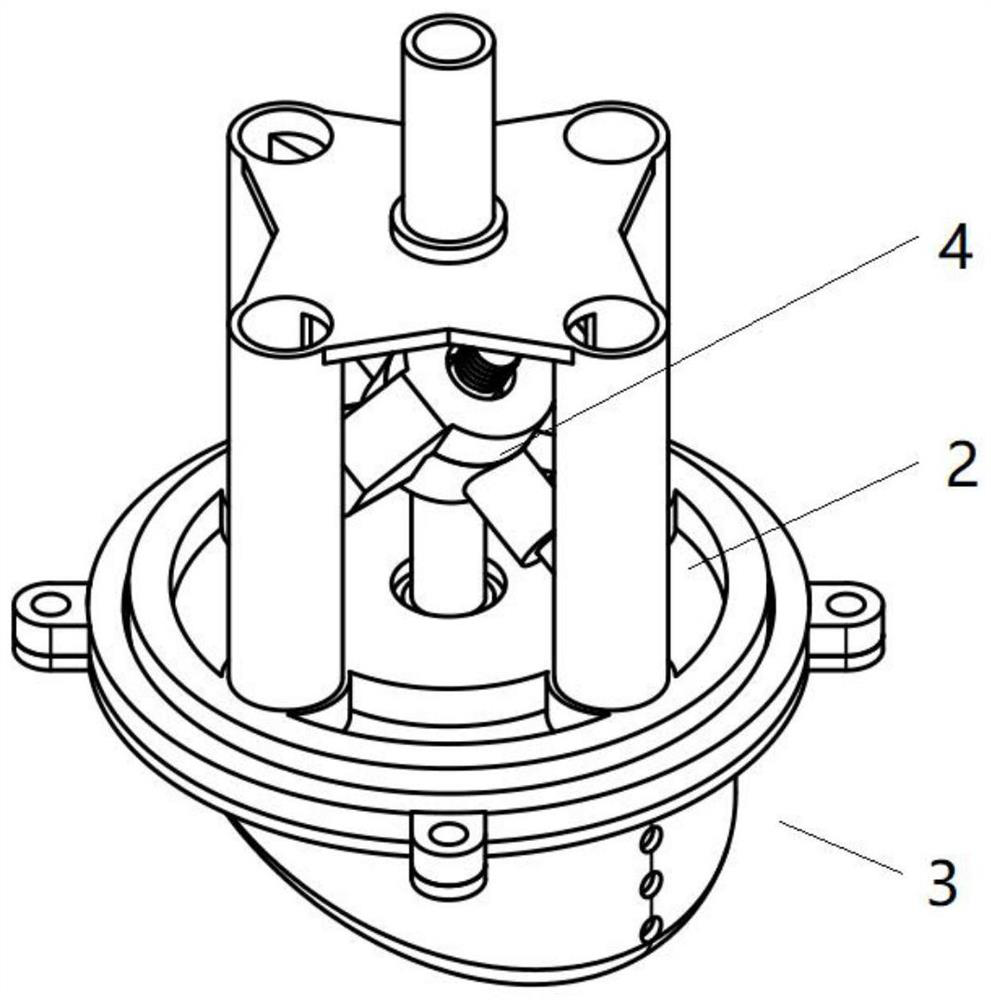

[0048] Such as Figure 1-12 As shown, Embodiment 1 provides an air motor, which includes a frame 1 , a rotor 2 , a cylinder 3 , a swash plate 4 and a paddle rod 5 .

[0049] An installation space is provided inside the frame 1 , a first shaft hole 11 is provided at one end of the frame 1 , fifth bearings are provided at both ends of the first shaft hole 11 , and the other end of the frame 1 is an open structure. Specifically, the frame 1 includes a mounting plate 12 and a plurality of mounting columns 13, the mounting columns 13 are evenly fixed on the edge of the mounting plate 12, and the multiple mounting columns 13 are located on the same side of the mounting plate 12, and the mounting columns 13 are far away from One end of the mounting plate 12 is provided with a lug 14 for connecting the cylinder body 3 , and the first shaft hole 11 is located at the center of the mounting plate 12 .

[0050] The rotor 2 includes a cylinder head 21 , a cover plate 22 , an output shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com