Control system special for down-the-hole drill carriage

A control system and down-the-hole drilling technology, which is applied to the automatic control system of drilling, the driving device for drilling in the wellbore, and the drill pipe. To achieve the effect of improving operation performance, simplifying working conditions and maintaining constant load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

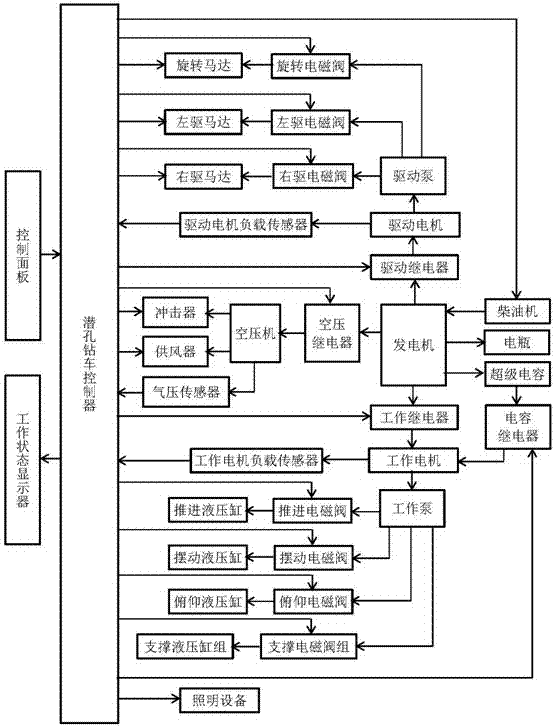

[0009] Such as figure 1 As shown, the special control system for down-the-hole drilling rig includes down-the-hole drilling rig controller, control panel, working status display, rotary motor, rotary solenoid valve, left drive motor, left drive solenoid valve, right drive motor, right drive solenoid valve, Drive pump, drive motor load sensor, drive motor, drive relay, impactor, air supply device, air pressure sensor, air compressor, air pressure relay, generator, diesel engine, battery, super capacitor, working relay, capacitor relay, working motor Load sensor, working motor, capacitor relay, propulsion hydraulic cylinder, propulsion solenoid valve, working pump, swing hydraulic cylinder, swing solenoid valve, pitch hydraulic cylinder, pitch solenoid valve, support hydraulic cylinder group, support solenoid valve group, lighting equipment; submersible The controller of the drilling rig is connected with the working status display, diesel engine, rotary motor, rotary solenoid v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com