Rapid slip-casting capsule type plugging technology for oil transmission pipeline

A technology for oil pipelines and grouting bags, which is applied to pipe components, pipes/pipe joints/fittings, mechanical equipment, etc., and can solve problems such as long operation time, unsatisfactory conditions, and complicated installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

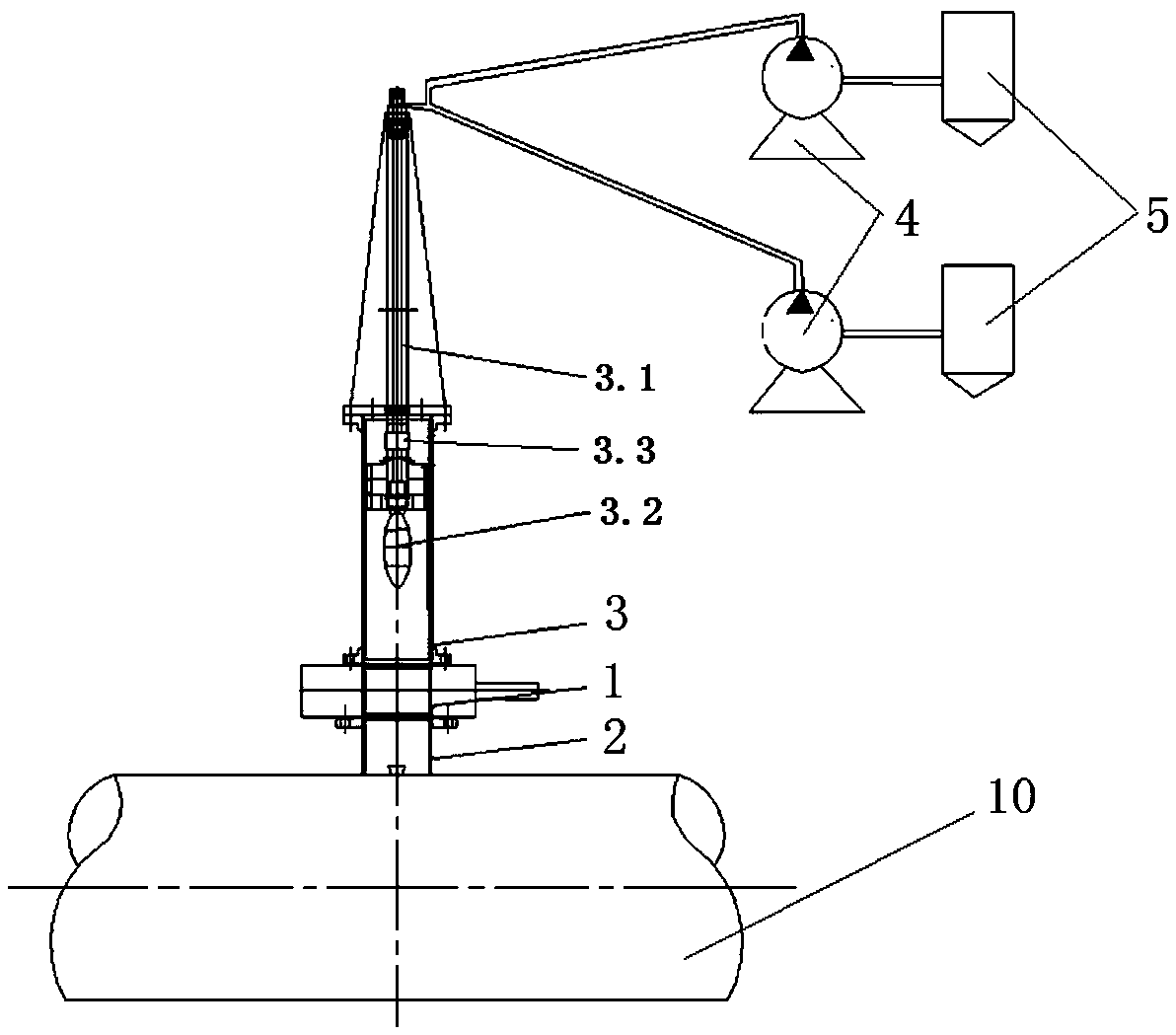

[0047] The rapid grouting bladder plugging process for oil pipelines, the specific steps of the process are as follows:

[0048] 1) Pipeline stop and pressure relief: For pipelines 10 that need emergency repair and emergency rescue, the pipeline should be stopped and pressure released first;

[0049] 2) Making operation pits: dig operation pits according to the emergency repair and emergency positions, and the depth of the pits can be below the center line of the pipeline;

[0050] 3) Welding and manufacturing of opening short joint: Weld the prefabricated opening short joint 2 to the pipeline 10 that needs to be repaired and rescued;

[0051] 4) Hole opening: Install the splint valve 1 and the opening machine. The lower end of the splint valve 1 is connected with the opening short joint 2 with bolts, and the upper end is connected with the flange of the opening machine, and the opening machine is started to open the hole;

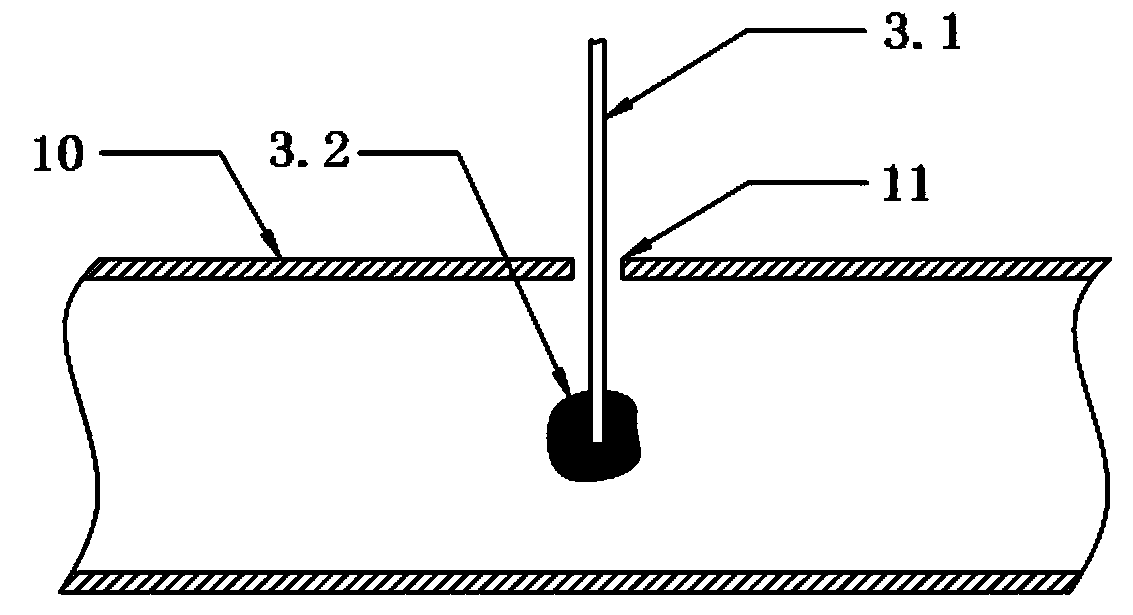

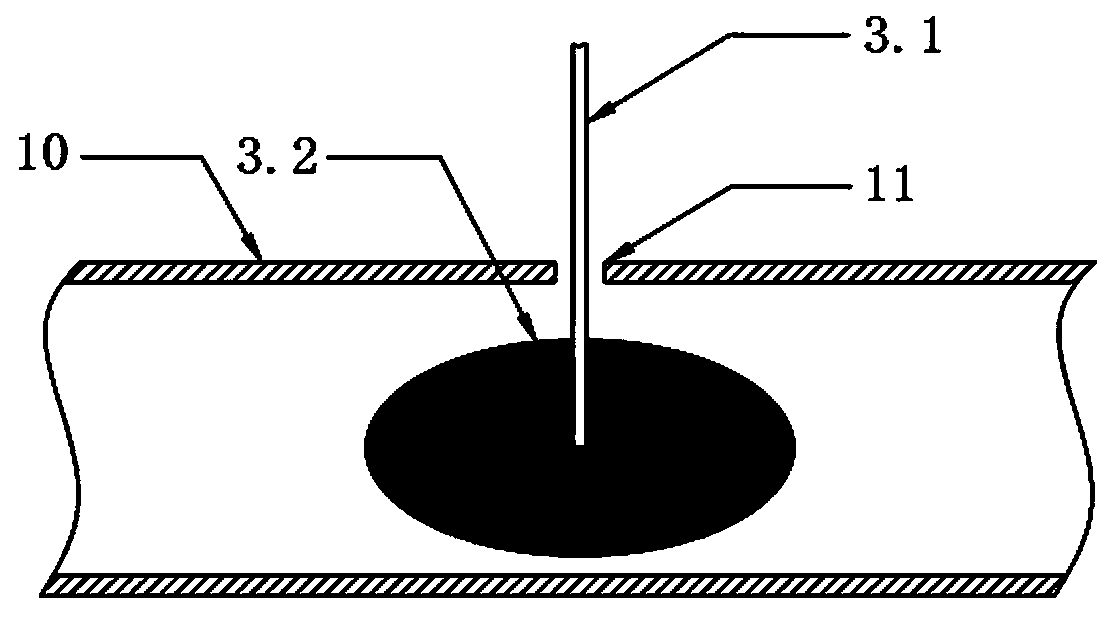

[0052] 5) Assemble the grouting plugging device: As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com