Pipe culvert test system used under inhomogeneous deformation and test method thereof

A test system and uniform deformation technology, applied in the field of pipe and culvert test systems, to achieve reliable test results and simple system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

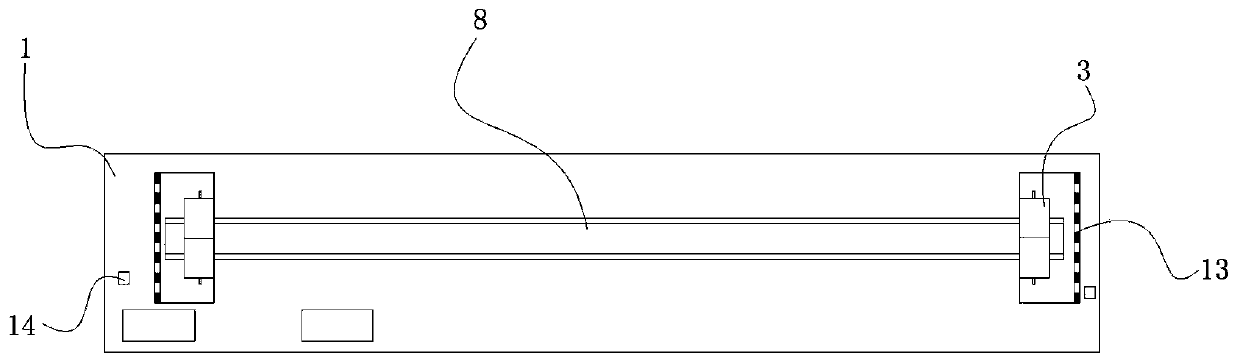

[0026] This embodiment discloses a pipe and culvert test system under uneven deformation, including a test bench 1, two sets of drive systems and a test data acquisition system.

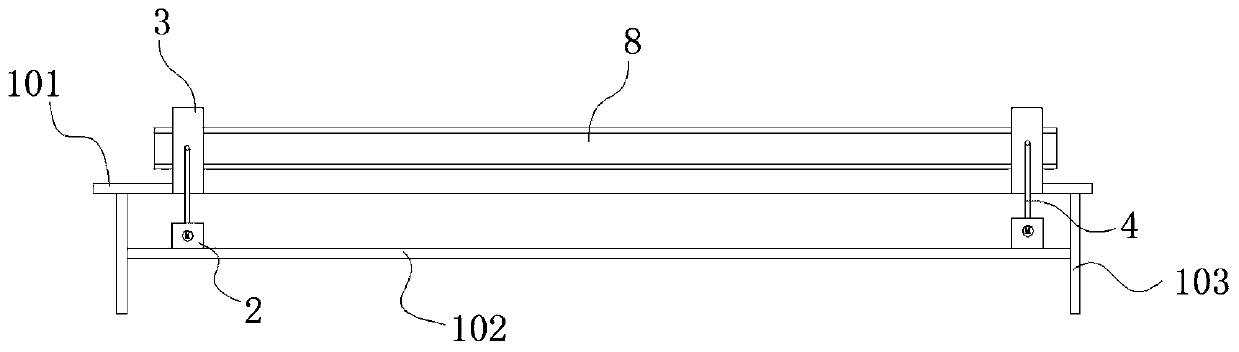

[0027] The test bench 1 includes an upper platform board 101 and a lower platform board 102 , and supporting legs 103 supporting the upper platform board 101 and the lower platform board 102 .

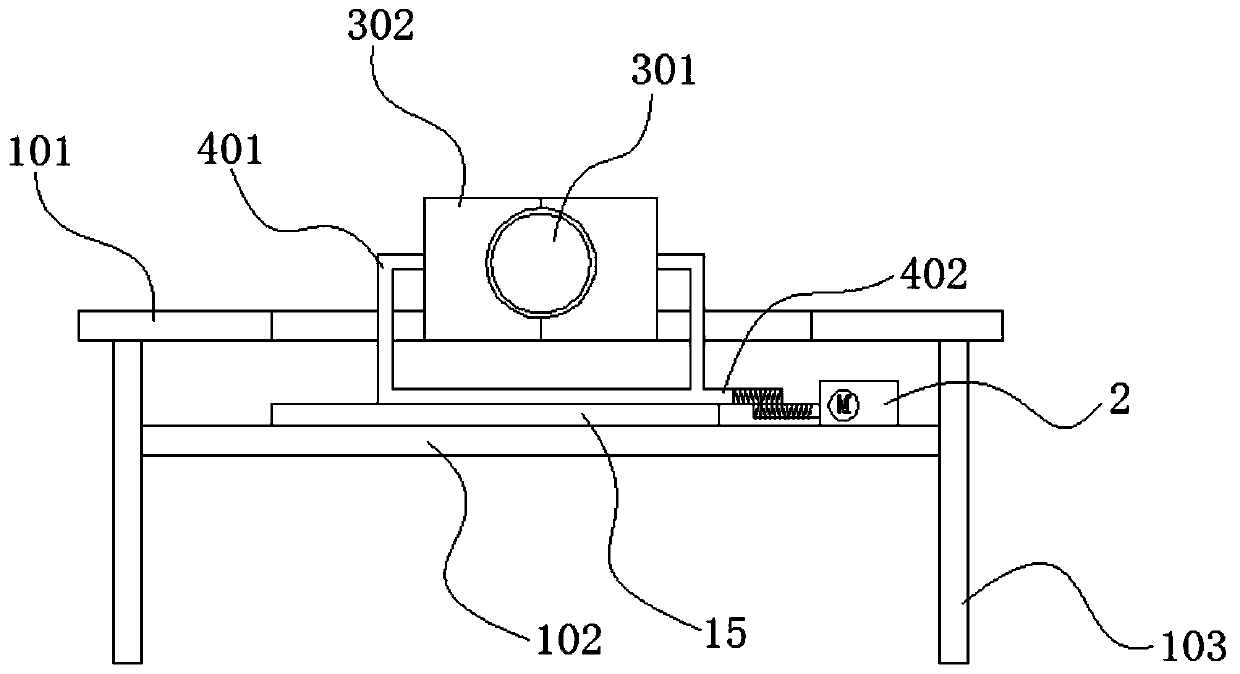

[0028] Each group of driving systems includes a driving motor 2 , a pipe culvert clamp 3 , a transmission rod 4 and a guide rail 15 . The guide rail 15 is fixed on the lower platform board 102 . The transmission rod 4 includes a transmission rod main body 401 and a connecting portion 402 arranged beside the transmission rod main body 401 . The transmission rod main body 401 is placed above the guide rail 15 . The upper platform board 101 is provided with a hollow part at a position corresponding to the main body of the transmission rod 401 . The upper end of the transmission rod main body 401 protrudes fro...

Embodiment 2

[0033] This embodiment discloses a test method for the pipe and culvert test system described in Example 1, comprising the following steps:

[0034] 1) Put the test bench 1 in an appropriate position and turn on the power. Adjust the two sets of pipe culvert clamps 3 to their original positions.

[0035] 2) Place the pipe culvert 8 in the center and clamp it with the pipe culvert clamp 3 .

[0036] 3) Lay out the test data acquisition system, and read the initial value after debugging.

[0037] 4) Adjust the transmission rod 4 to simulate the settlement of the pipe culvert 8 .

[0038] 5) Record the reading of the pointer on the scale according to the number of the test bench, and the monitoring equipment collects the test data.

[0039] 6) Remove the test data acquisition system and remove the pipe culvert 8.

[0040] 7) Data processing, researching the relationship between the displacement and internal force of the pipe culvert 8 according to the data.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com