Transfer device and manufacturing method of display substrate

A technology for transferring devices and display substrates, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc. It can solve the problems of low manufacturing yield of display substrates, achieve the effect of simplifying the manufacturing process and improving the manufacturing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

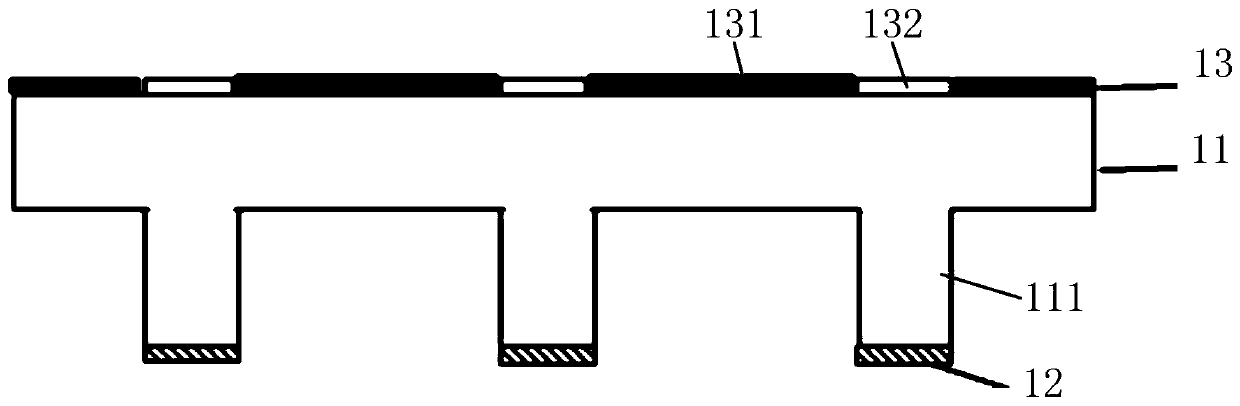

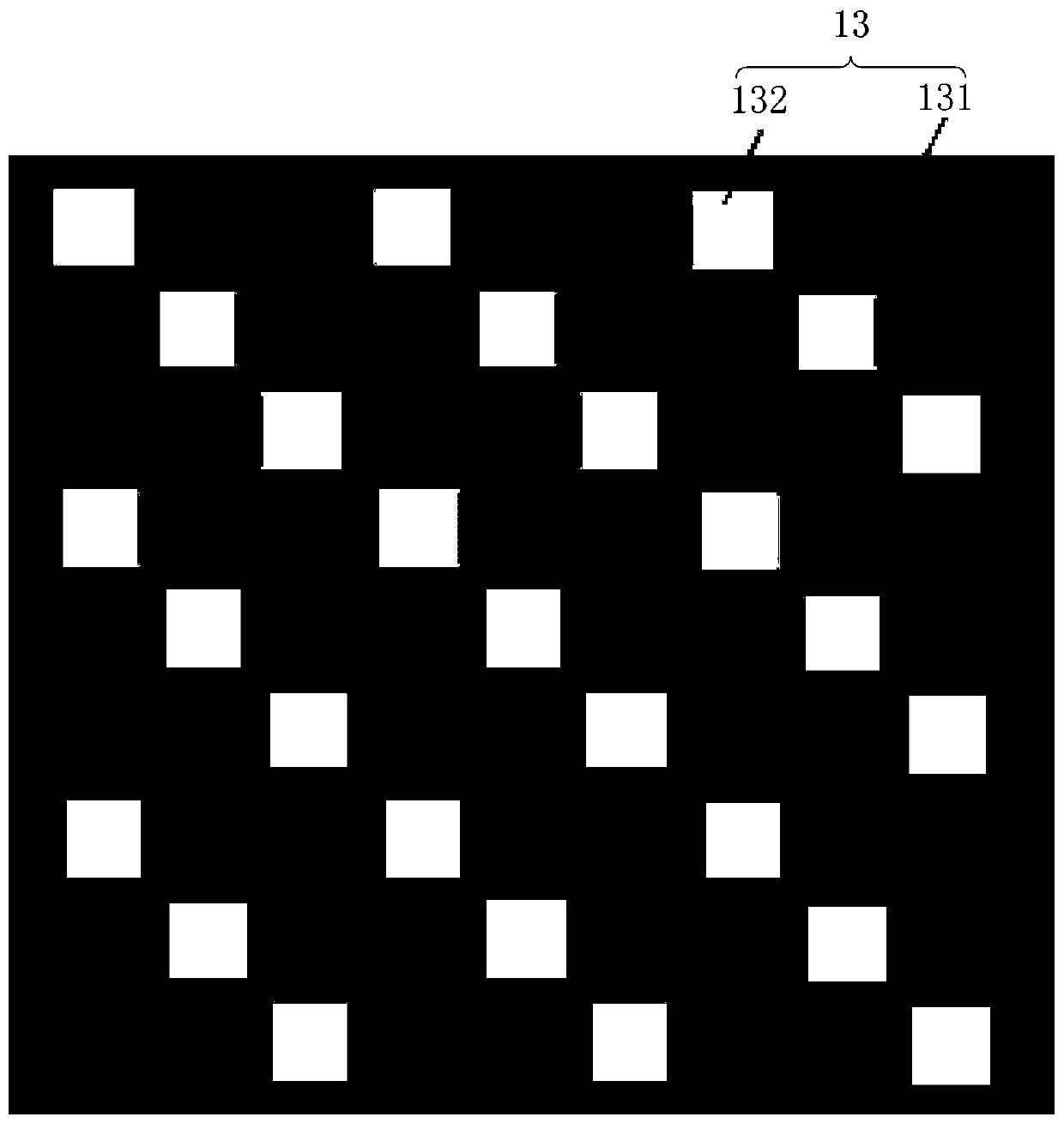

[0036] see figure 1 , the embodiment of the present invention provides a transfer device 1, comprising: a transparent carrier 11; one side surface of the transparent carrier 11 is provided with a plurality of adhesive parts 12 arranged at intervals, and the adhesive parts 12 adopt photosensitive Adhesive material; the other side surface of the transparent carrier 11 is provided with a plurality of opaque patterns 131, and the orthographic projection of the gap between the opaque patterns 131 on the transparent carrier 11 is related to the adhesive portion The orthographic projections of 12 on the transparent carrier 11 overlap.

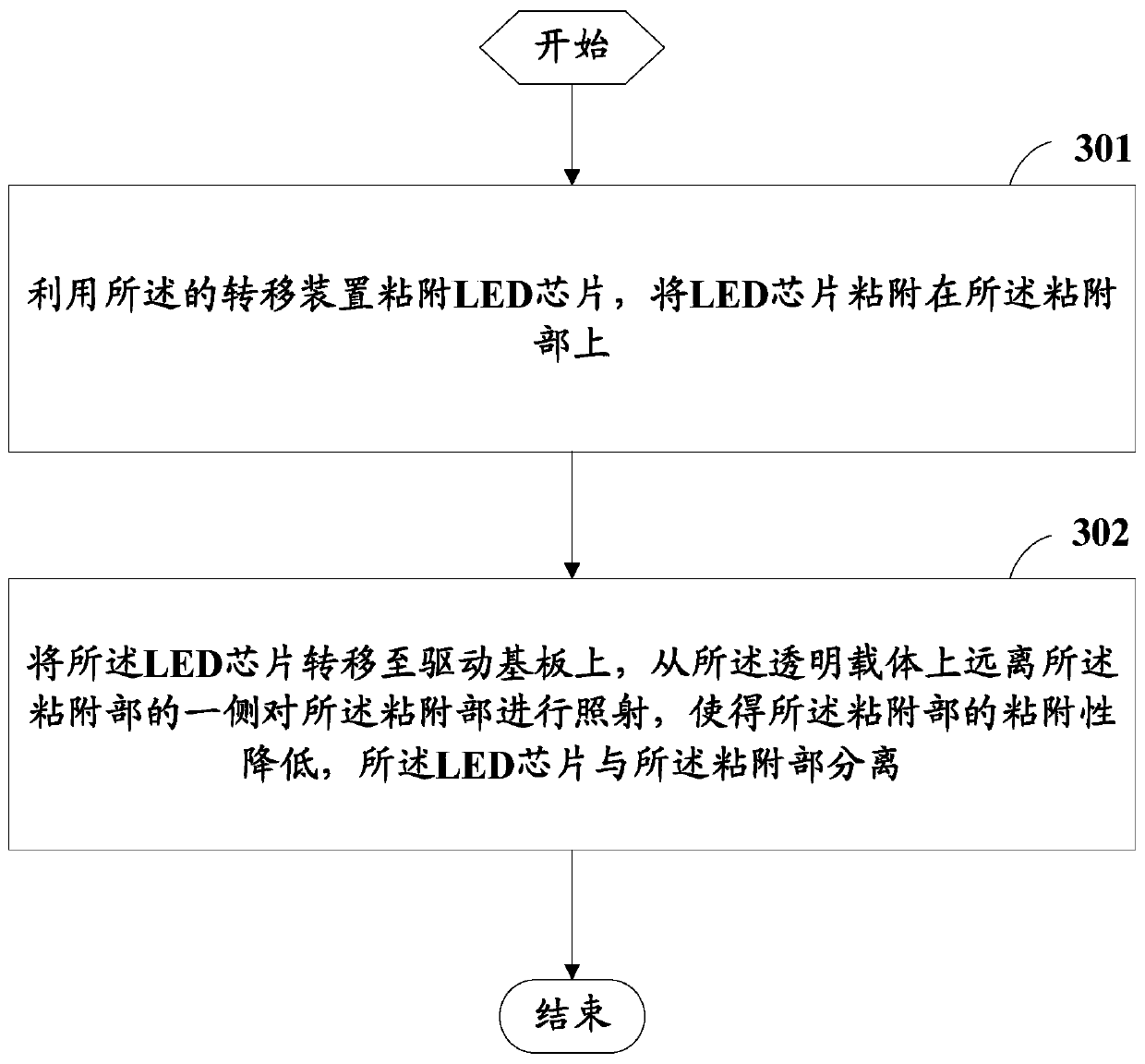

[0037] In the embodiment of the present invention, the adhesive part 12 is a photosensitive adhesive material. When the adhes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com