Multi-lobe cylindrical low-frequency mechanical antenna structure

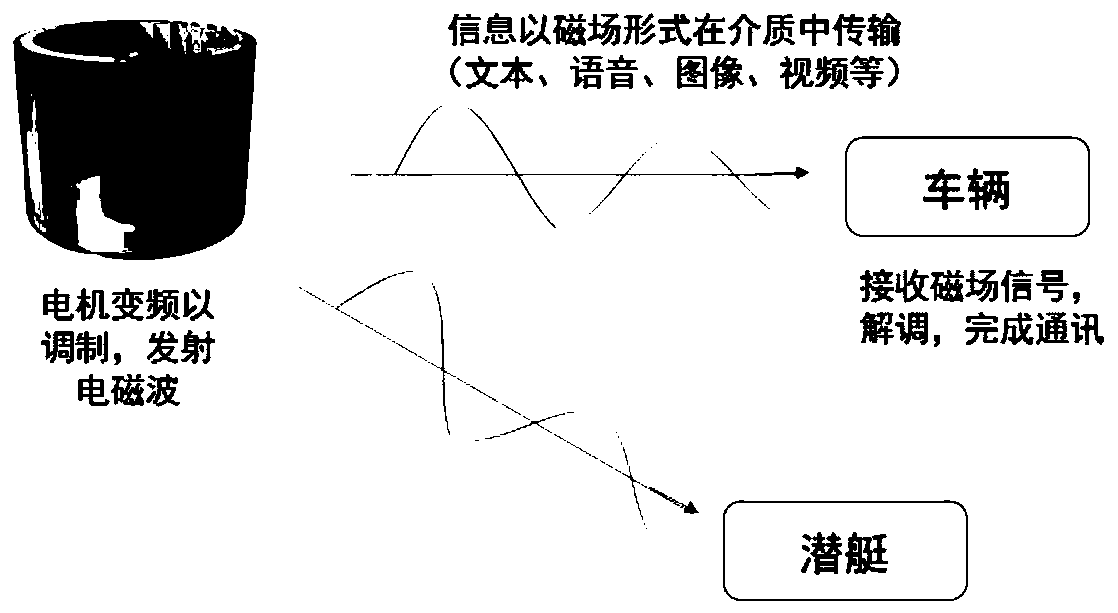

A cylindrical, antenna-structured technology, used in antennas, antenna supports/installation devices, and devices that enable antennas to work in different bands at the same time. The problem of large size of the antenna, etc., to achieve the effect of high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following will clearly and completely describe the technical solutions in the embodiments of the present application with reference to the accompanying drawings in the specification of the present application. Obviously, the described embodiments are only for illustration, and are not intended to limit the present application.

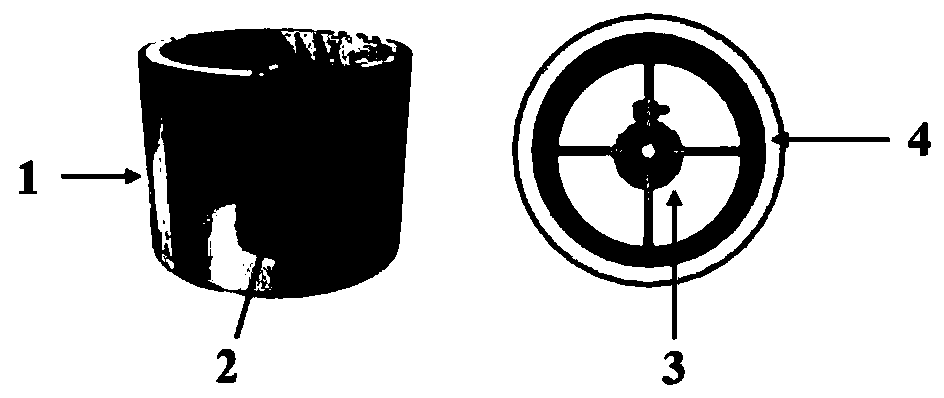

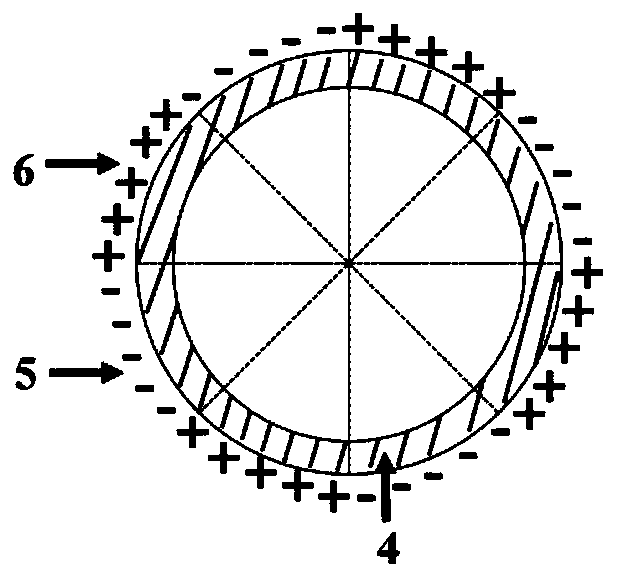

[0019] The present invention provides a multi-lobe cylindrical low-frequency mechanical antenna structure. The low-frequency antenna is composed of a support frame 3 , a rotating motor 2 , an antenna shell (support structure) 4 , and multiple electret films 1 .

[0020] The supporting frame 3 is connected with the rotating motor 2 and the antenna shell 4, and the supporting frame 3 is driven by the rotation of the motor, and then the connected mechanical antenna shell 4 and the electret film 1 are driven to rotate.

[0021] The rotational speed of the rotating electrical machine 2 is relatively high, and the sensitivity of frequency conversio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com