Nitrogen production and adsorption tower with air volume more than 500 cubic meters and method for determining calibers of inlet and exhaust ports of nitrogen production and adsorption tower

An adsorption tower and air inlet technology, applied in the field of nitrogen production equipment, can solve problems such as regeneration of adsorbents, achieve smooth exhaust, ideal nitrogen production indicators, and good analysis effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

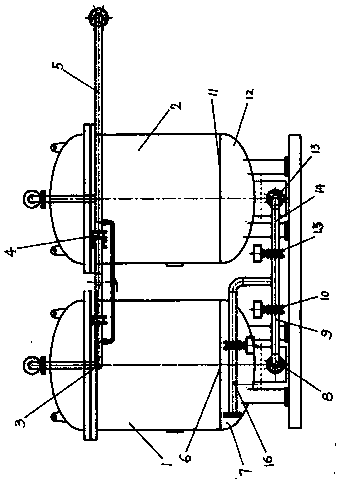

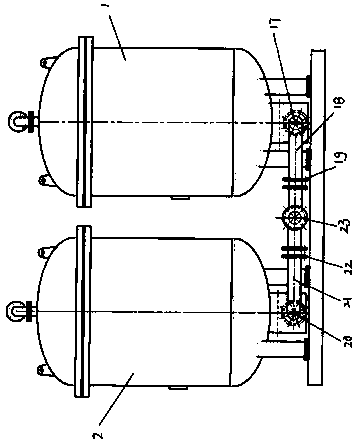

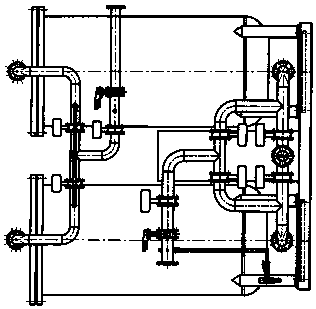

[0018] The present invention is described in detail below in conjunction with accompanying drawing:

[0019] An adsorption tower for nitrogen production with a capacity of more than 500 cubic meters, comprising a first adsorption tower 1 and a second adsorption tower 2, a first adsorption tower gas production port 3 is arranged at the top of the first adsorption tower 1, and a first adsorption tower gas production port 3 is arranged at the top of the second adsorption tower The gas production port 4 of the second adsorption tower is provided, and the gas production port 3 of the first adsorption tower and the gas production port 4 of the second adsorption tower are connected together with the nitrogen collection main pipe 5; the bottom of the first adsorption tower 1 is provided with a first adsorption tower The buffer chamber 7 is provided with the first adsorption tower support flower plate 6 above the buffer chamber 7 of the first adsorption tower, and the second adsorption ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com