Conveying device of horizontal loop

A technology of conveying equipment and loopers, applied in the field of conveying equipment of horizontal loopers, can solve the problems of reducing the production efficiency of the unit, unstable stop of the idler, and uneven operation of the strip, avoiding overlapping wear and ensuring The effect of service life and improvement of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to have a clearer understanding of the technical solutions, objectives and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

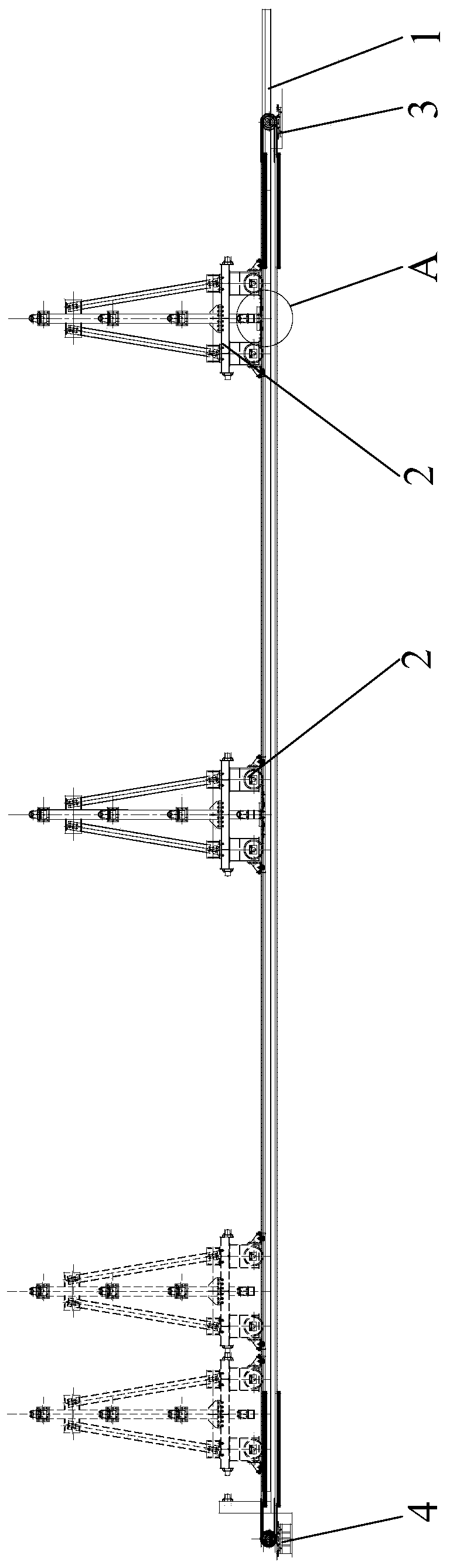

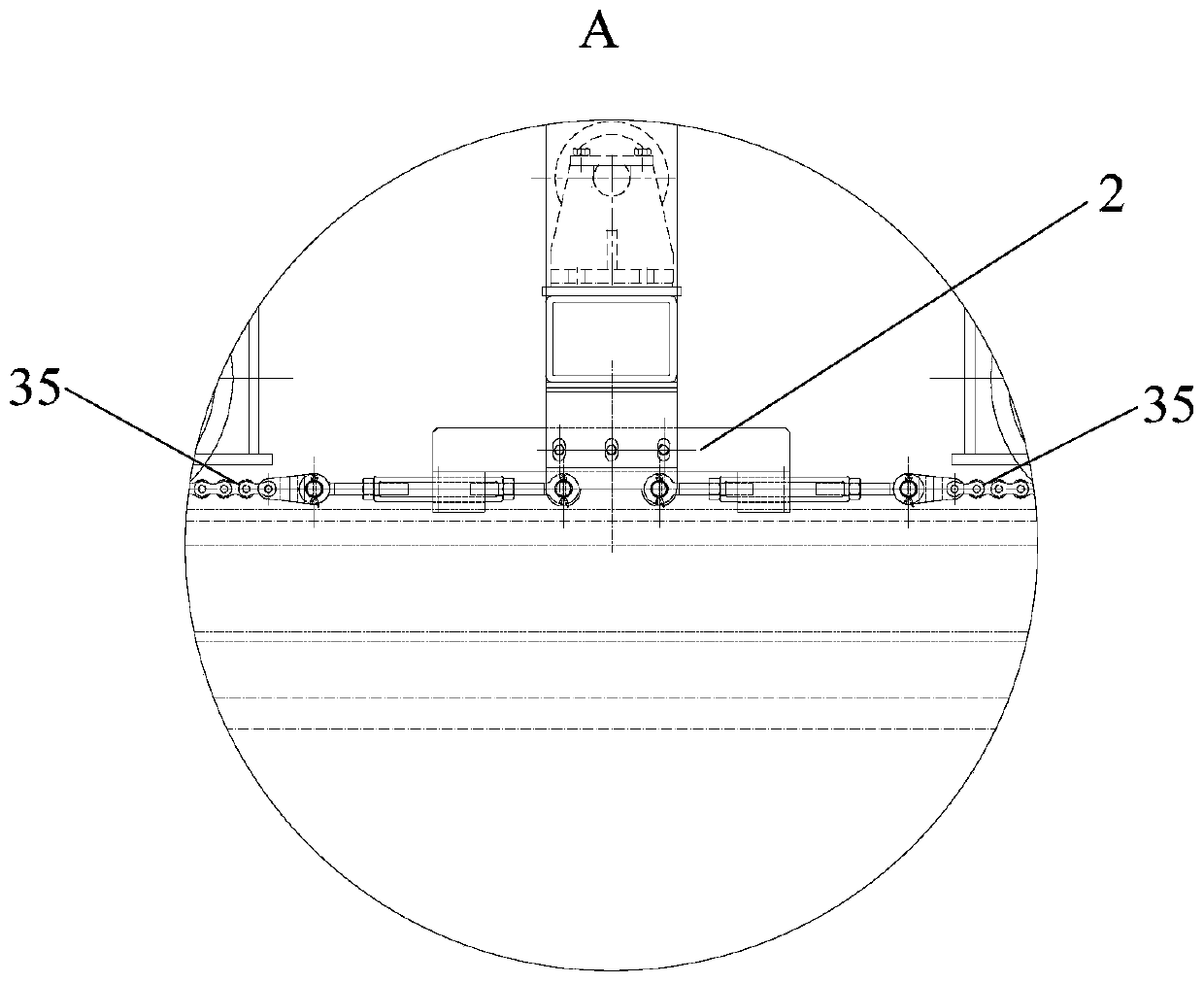

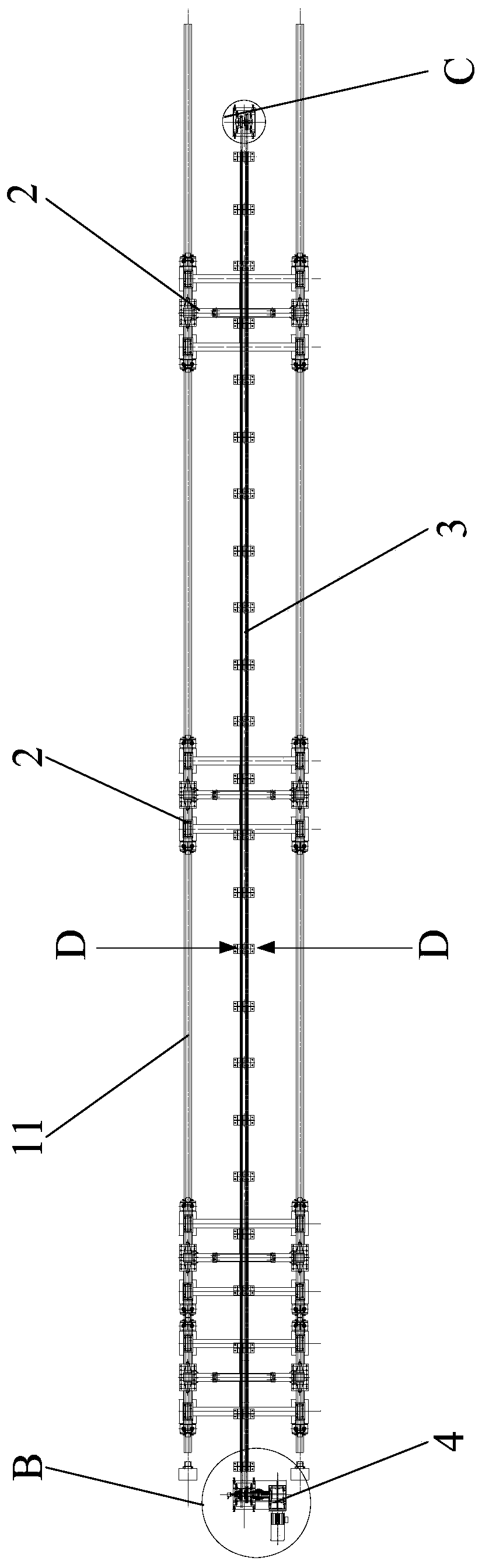

[0042] Such as figure 1 and image 3 As shown, the present invention provides a transmission device for horizontal loops, which includes a track 1, at least one idler car 2, a transmission mechanism 3 and a drive control mechanism 4, wherein:

[0043] Such as image 3 As shown, the track 1 includes two parallel and spaced slide rails 11, the idler trolley 2 is arranged on the track 1 and can move back and forth along the track 1, the slide rail 11 can guide the movement of the idler trolley 2, and the two The lengths of the slide rails 11 are equal, and the distance between the two slide rails 11 is approximately the same as the width of the idler cart 2, so that the idler cart 2 can move smoothly along the slide rails 11. I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com