Drying room device capable of preventing fading of dyed fabrics for rotary screen printing machine

A technology for printing machines and dye stoppers, applied in the field of drying room devices, can solve problems such as unfavorable printing quality of textile products, long production time and cycle, and jittering of printed and dyed materials, and achieve stable and reliable temperature rise, stable and reliable speed, and easy control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

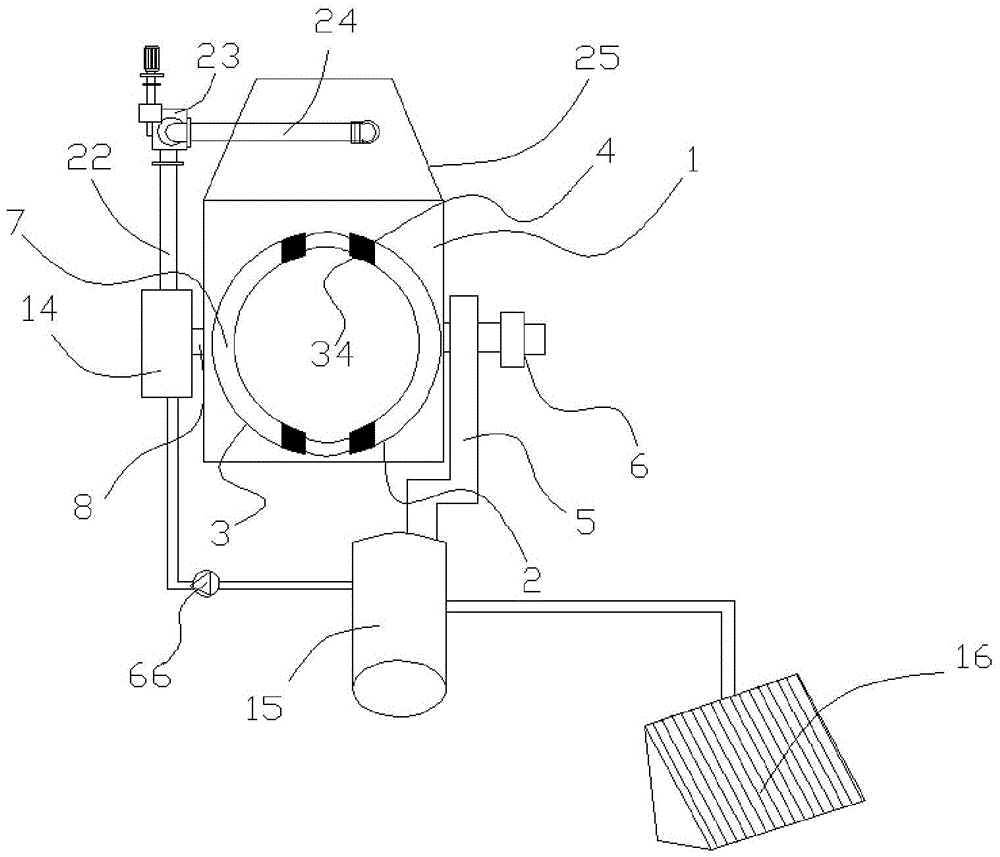

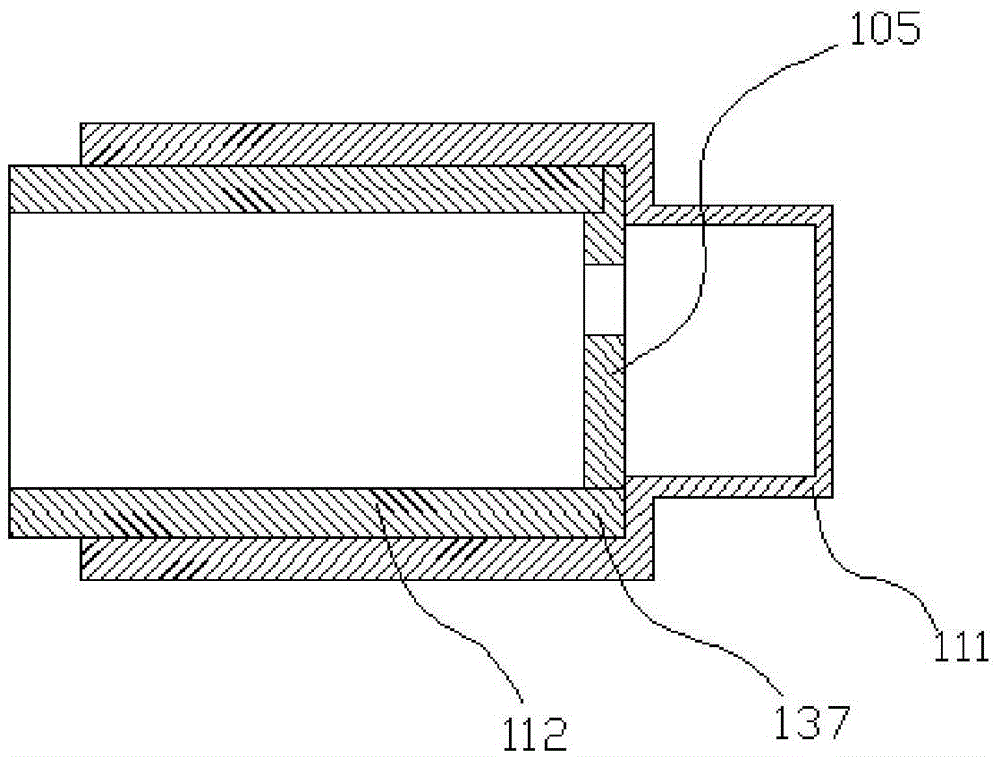

[0021] Such as figure 1 As shown, a drying room device of a rotary screen printing machine that can prevent the dyed matter from fading includes a drying room 1, and a left drying pan 3 and a right drying pan 2 are relatively placed in the drying room 1, and the left drying pan 3 and the The right baking tray 2 is a semicircular disc body, the right baking tray 2 is connected with the hot water storage tank 15 through the support 5, the right baking tray 2 and the support 5 are provided with a cylinder 6, and the left baking tray 2 The inside of the tray 3 is a cavity 7, and the interface 8 communicating with the cavity 7 is arranged on the outer wall of the drying room 1, and the interface 8 communicates with the intermediate water tank 14, and the intermediate water tank 14 is connected to the hot water storage tank 15, The hot water storage tank 15 is provided with hot water by the solar heat collector 16. In the present invention, since the left and right drying plates are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com