Cutting device for thermally cutting a running, in particular, patterned textile web

A cutting device and material web technology, which are applied in the cutting of textile materials, textile and papermaking, metal processing, etc., to achieve the effects of less heat dissipation, improved sliding properties, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

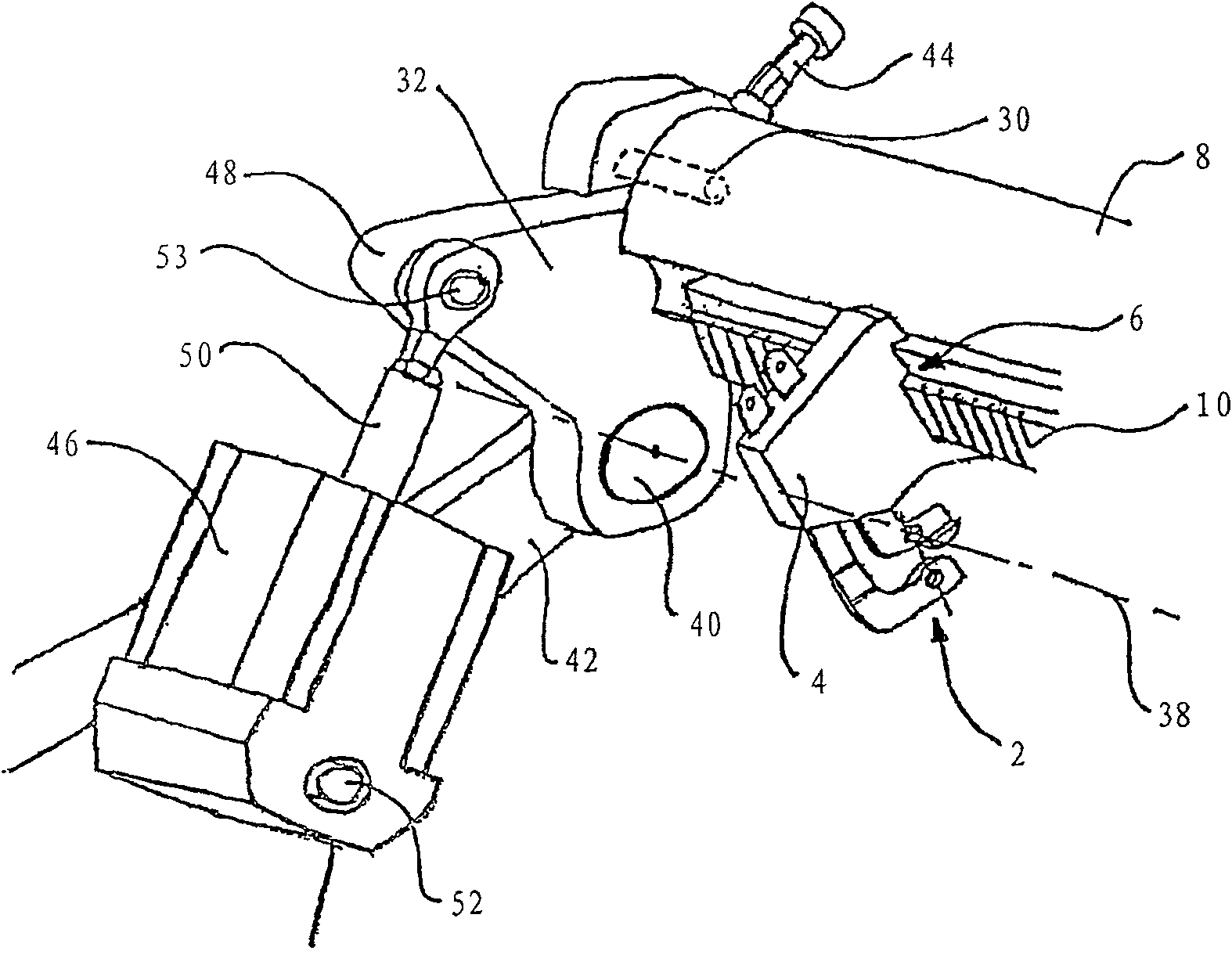

[0030] figure 1 A cutting device is shown which has one or preferably several cutters 2 , the housing 4 of which is arranged adjustable via a longitudinal guide 6 on a transverse beam 8 . The crossbeam 8 overlaps the textile web and is, for example, part of a weaving machine, so that such a cutting device can be arranged transversely to the web path of the weaving machine in order to carry out a corresponding cut in the textile web. In particular, a wide patterned textile web can be cut into strips, preferably patterned labels. The width of the strap is adjusted by means of the scale 10 of the longitudinal guide 6 .

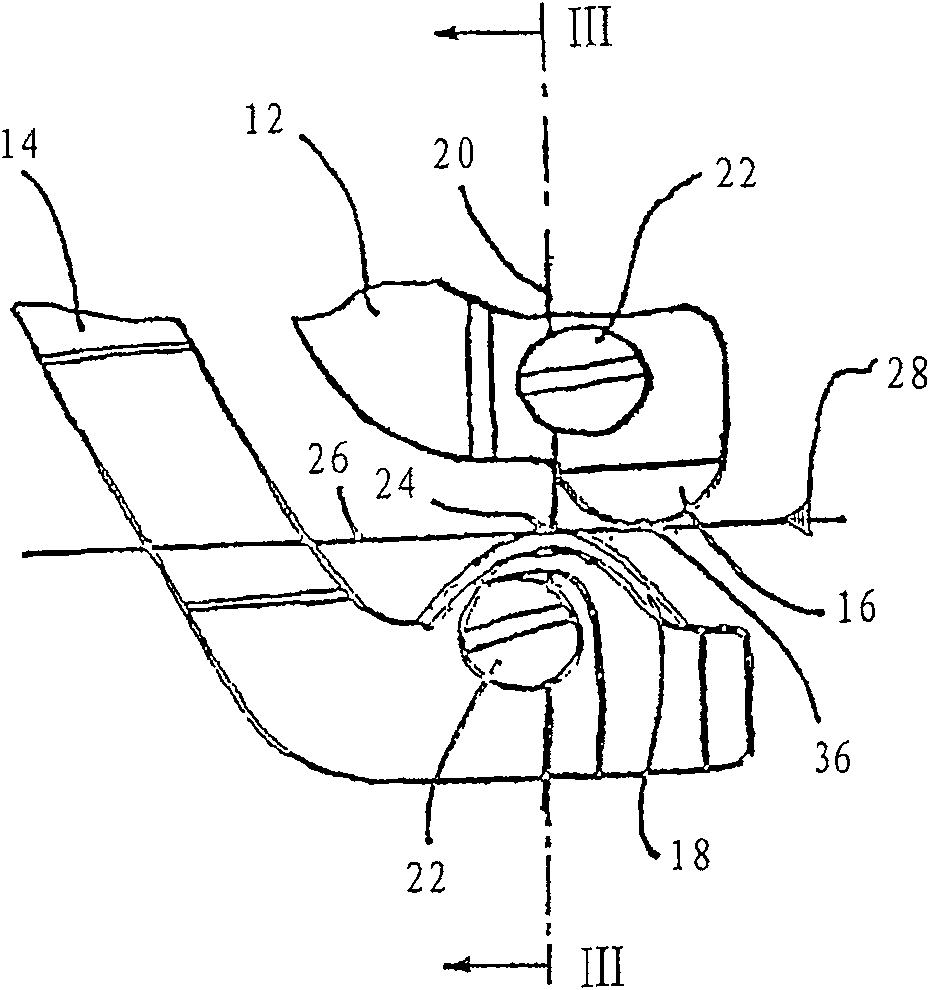

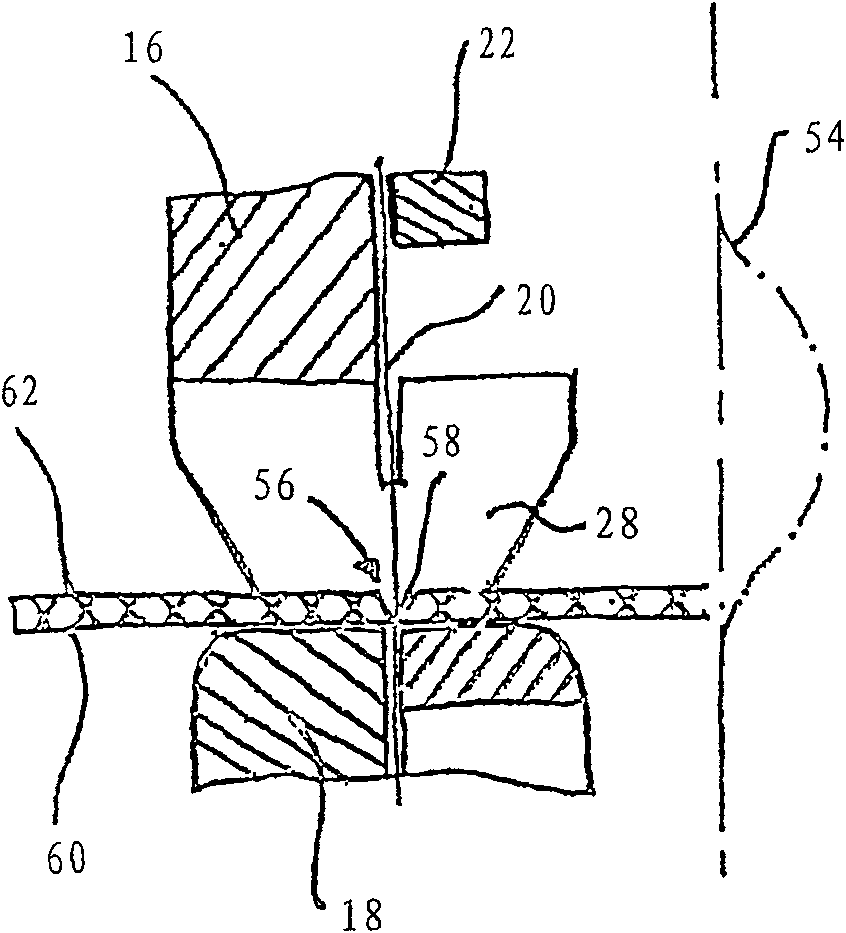

[0031] as in Figures 1 to 3 Shown in, support 12,14 is fixed on the shell 4 of cutter 2, and one of support 12,14 has a pressure head 16 and another has a support 18, for example by screw between pressure head and support 22 clamp an electric heating filament cutter 20. The support 18 has a curved shape, the apex 24 of which is used on the one hand to suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com