Automatic gluing production system and gluing process for motor rotor slices

A technology for motor rotors and production systems, which is applied to coatings, devices for coating liquids on surfaces, and pretreatment surfaces, etc., can solve problems such as unenvironmental protection, uneven gluing, and increase motor production costs, and achieve convenient operation, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

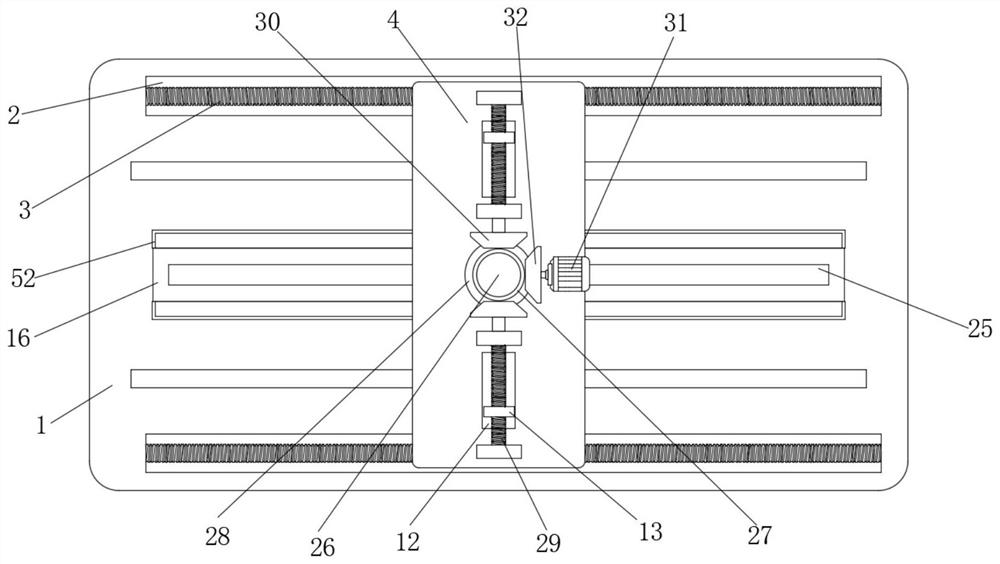

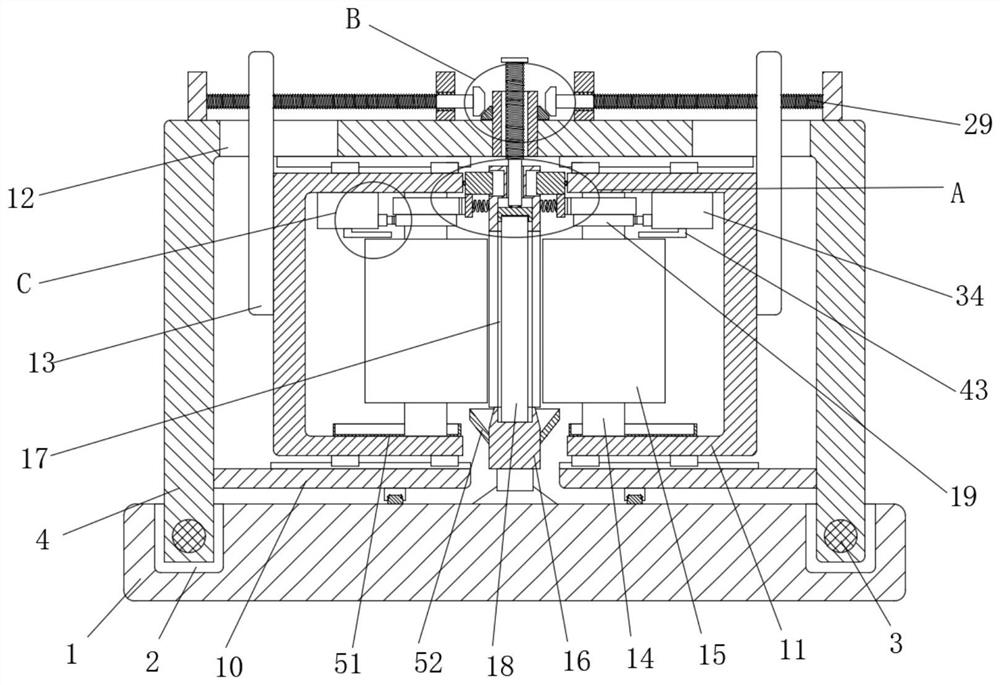

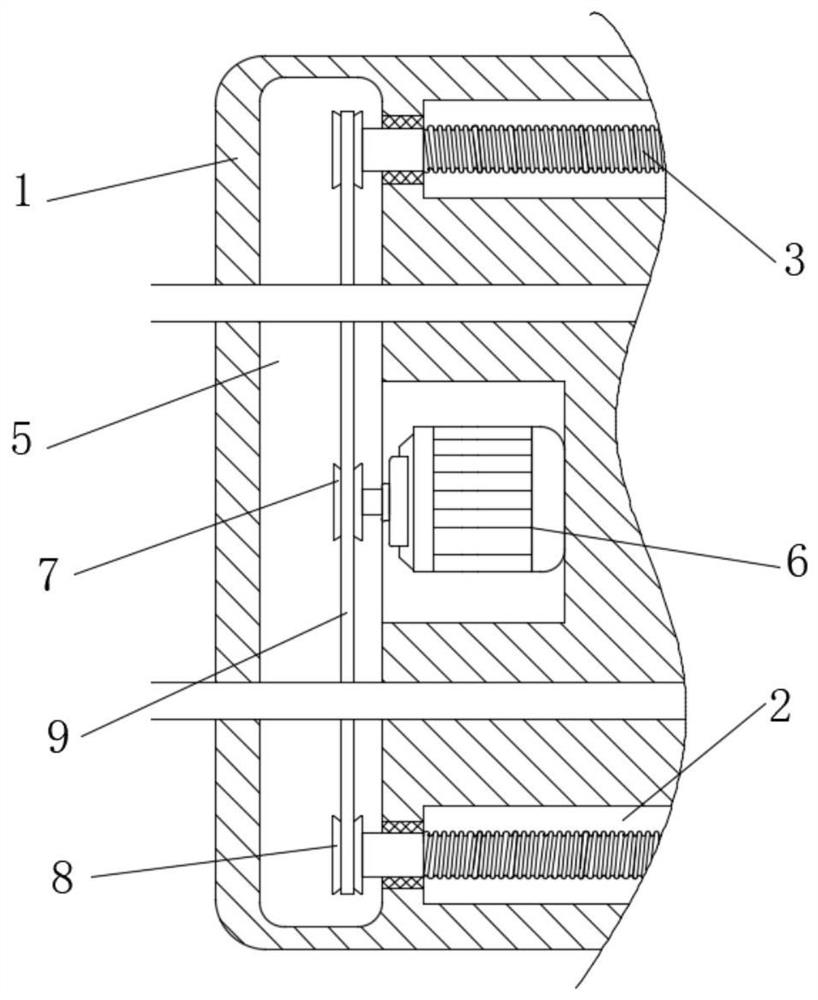

[0049] refer to Figure 1-15 , an automatic gluing production system for motor rotor slices, including a worktable 1, two symmetrical rotating grooves 2 are arranged on the top of the working table 1, and the same first U is slidably connected to the inner walls of the two sides of the two rotating grooves 2 Model plate 4, the driving assembly that is used to make the first U-shaped plate 4 move is provided in the workbench 1, and the top of the workbench 1 is fixedly connected with a placement frame 16, and the placement frame 16 is provided with a placement groove 17, and the placement groove 17 The inner wall of the bottom is provided with a rotor piece 18, the top of the first U-shaped plate 4 is provided with a fixing assembly for fixing the rotor piece 18, the top of the first U-shaped plate 4 is connected with a nut 27 for rotation, and the outer wall of the nut 27 is fixedly sleeved. A bevel gear 28, the inner walls on both sides of the first U-shaped plate 4 are fixed...

Embodiment 2

[0063] Embodiment two: if Figure 16As shown in -17, a kind of automatic gluing production system for motor rotor slices, the difference between this embodiment and Embodiment 1 is that: the top of the first U-shaped plate 4 is fixedly connected with a blower 46 and a heating box 47, and the air outlet of the blower 46 Extending in the heating box 47, the top inner wall and the bottom inner wall of the heating box 47 are equidistantly arranged with a plurality of heating pipes 48, and both sides of the heating box 47 are provided with connected air outlet pipes 49, two air outlet pipes 49 One end of each nozzle is fixedly sleeved with a nozzle 50 , and the air outlets of the two nozzles 50 are aligned with the rotor blade 18 .

[0064] However, as is well known to those skilled in the art, the working principles and wiring methods of the driving motor 6, the rotating motor 31, the blower 46 and the heating pipe 48 are commonplace, and they all belong to conventional means or c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com