Apparatus for producing filters in the tobacco-processing industry

A filter, the industry's leading technology, applied in the field of filter devices, can solve the problem of high static state costs, etc., to achieve the effect of short structure length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

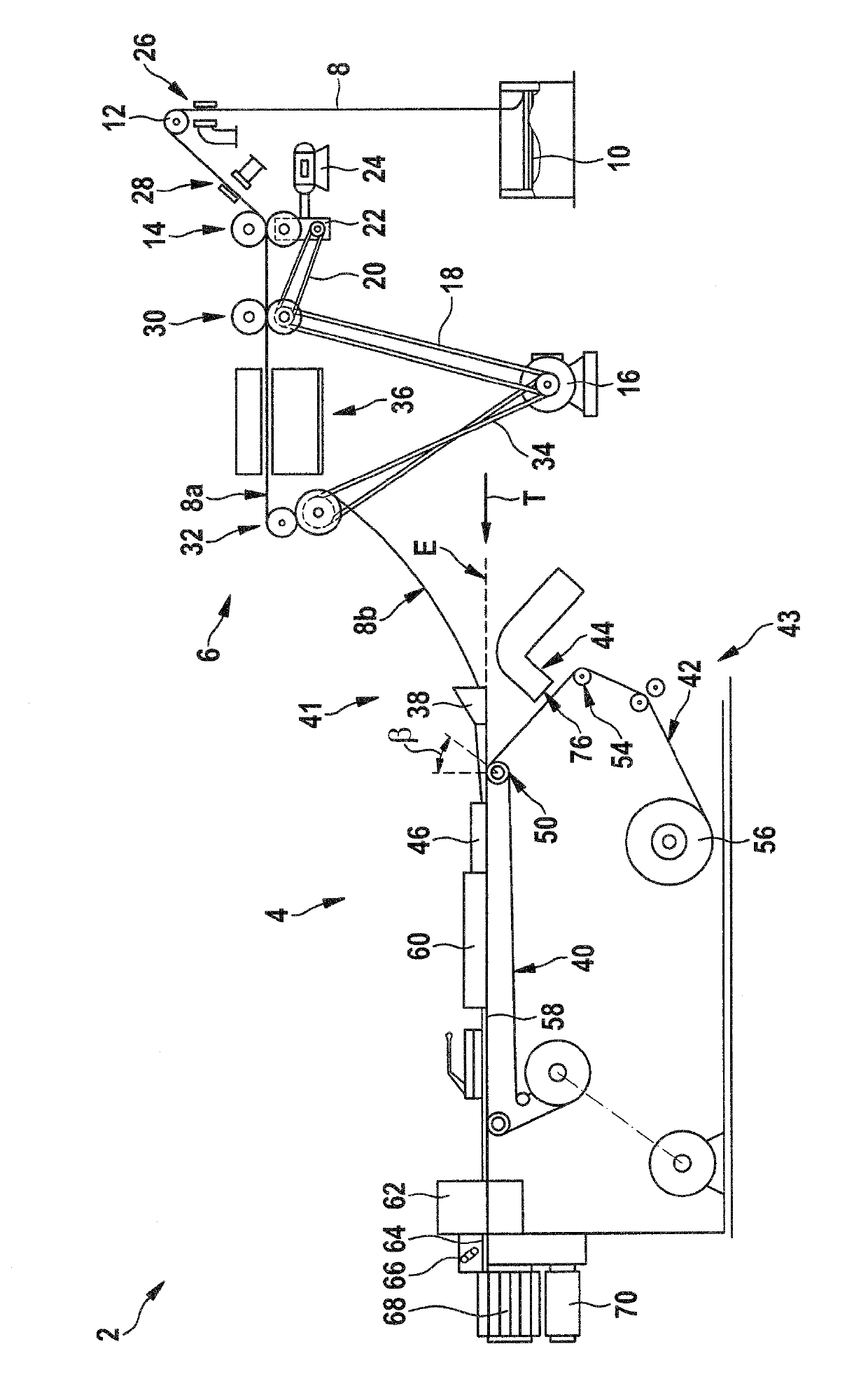

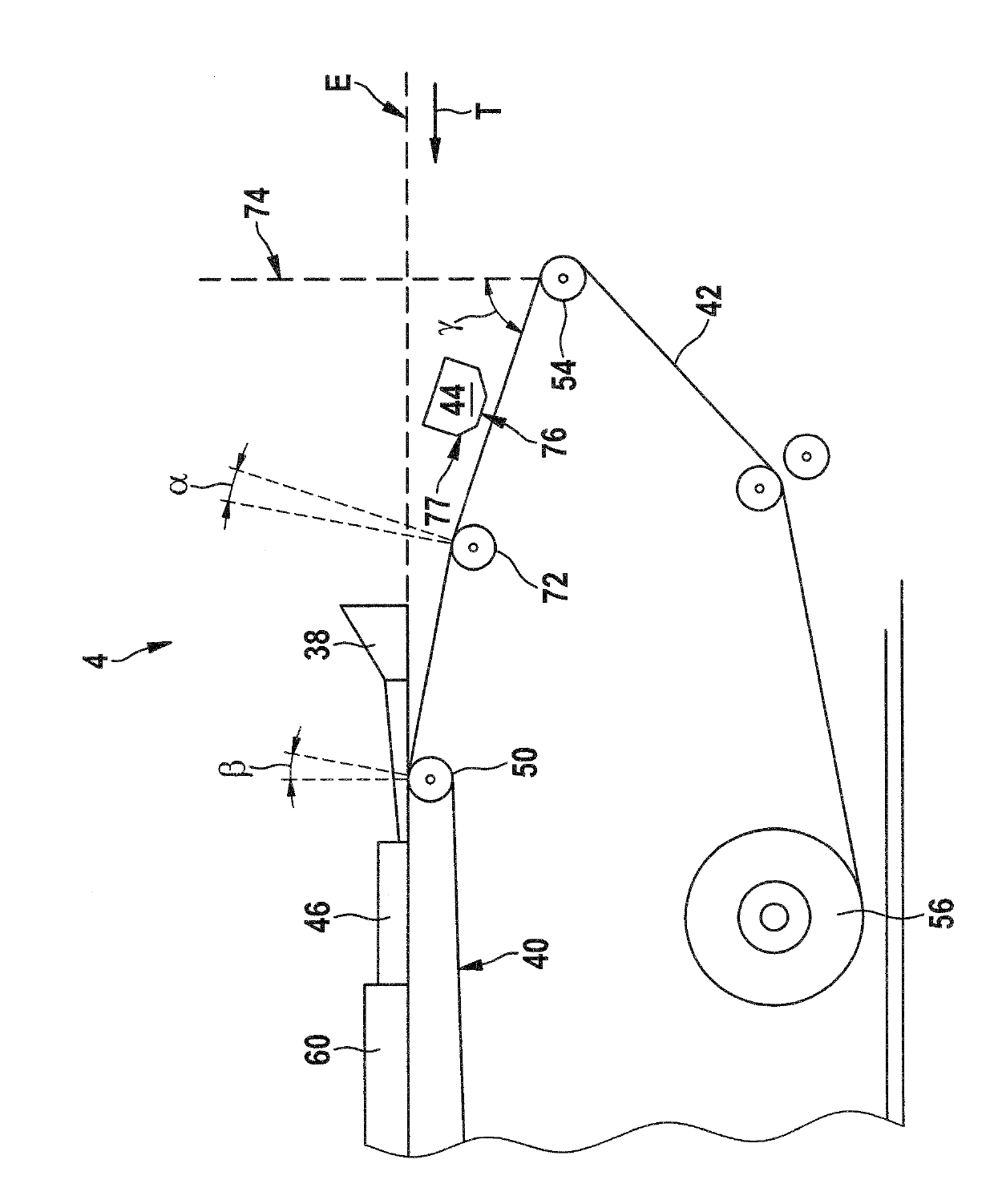

[0020] exist figure 1 A machine 2 for making filter rods is shown in . Said machine 2 generally has two main assemblies, namely a device 4 for making filters and a device 6 for preparing tow. The device 6 for preparing tow has a deflection wheel 12 and a roller pair 14 for continuously withdrawing an endless strip of filler material 8 from a filter pack 10 . The pair of rollers 14 can be driven by a main drive 16 via belt drives 18 , 20 and a transmission 22 . The transmission ratio of the transmission 22 can be varied by means of a servomotor 24 . The filling material 8 is drawn out of the filter pack 10 via the deflection wheels 12 by means of the roller pair 14 . Here, the filling material 8 passes through two air nozzles 26 , 28 which serve to prepare and loosen the fabric of the filling material 8 . The roller pair 14 is followed by two further roller pairs 30 , 32 . The roller pairs 30 , 32 can also be driven by means of the main drive 16 via belt drives 18 , 34 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com