Assembling clamp and device for inner sealing ring of clamping pipe

A technology of inner sealing ring and assembly fixture, which is applied in the direction of manufacturing tools and hand-held tools, etc., can solve the problems of low production efficiency and slow installation speed, and achieve the effect of improving installation efficiency and simplifying the installation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

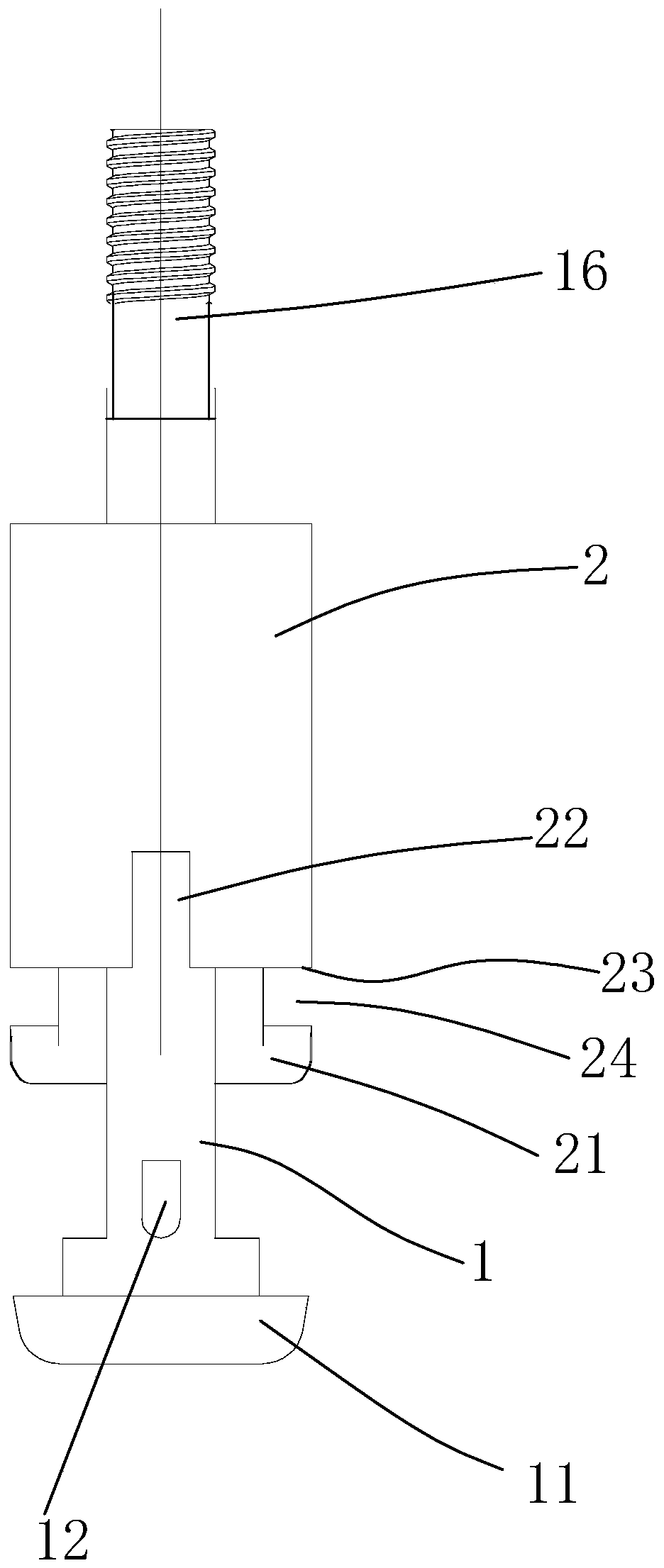

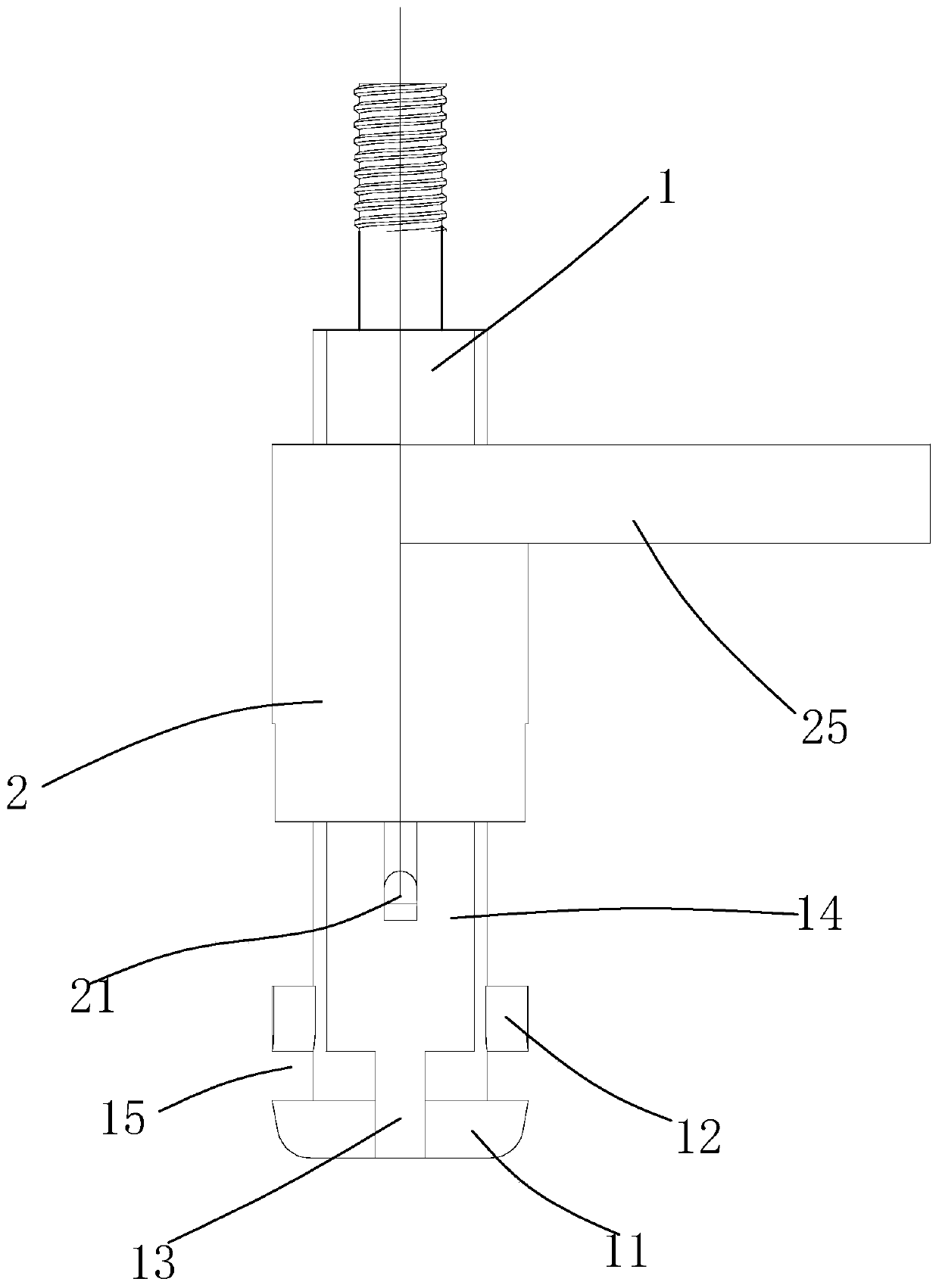

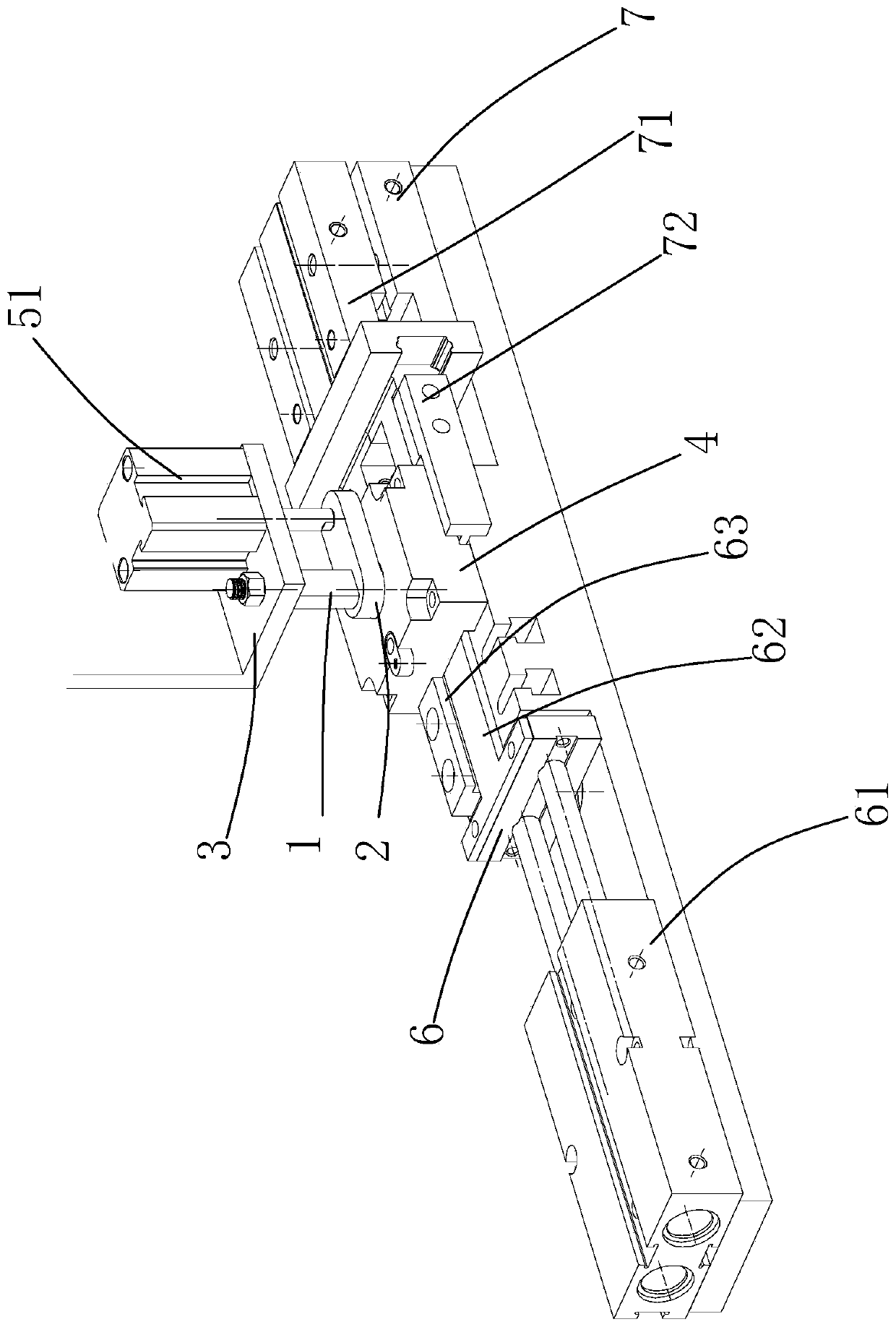

[0024] Embodiment one: refer to Figure 1 ~ Figure 2 , a jig for assembling an inner sealing ring of a pressed tube, comprising a push rod 1 and a sleeve 2, the sleeve 2 includes a cavity, and the upper end of the push rod 1 is inserted into the cavity of the sleeve, so The bottom of the push rod 1 includes a bottom plate 11, and the lower end of the push rod is provided with two opposite first hooks 12, and there is a gap 15 between the first hooks 12 and the bottom plate 11, and the sleeve 2 Two second hooks 21 opposite to each other are provided at the bottom, and the planes where the first hook 12 and the second hook 21 are located are perpendicular to each other. The sleeve 2 includes a bottom surface 23, and there is a gap 24 between the second hook and the bottom surface.

[0025] When working, the casing and the push rod are relatively separated by a certain distance, so that the first hook and the second hook form a certain height difference on the vertical plane, an...

Embodiment 2

[0026] Embodiment 2: In addition to four hooks, there may be two hooks, one for the first hook and one for the second hook, and the phase angle difference between the projections of the two hooks on the horizontal plane is about 180°. Since the two hooks are not located at the same projection position, when the relative positions of the two hooks change, the inner sealing ring can be stretched and deformed, so that the inner sealing ring can be hung on the two hooks. However, since there are only two hooks, a greater height difference is required to allow the inner sealing ring to generate enough elasticity to hang on the hooks when stretching.

[0027] Regardless of the above-mentioned embodiment, as a further preferred embodiment, the bottom plate 11 is provided with a through groove 13, and the through groove 13 is located directly below the second hook 21; the bottom of the sleeve 2 is provided with The notch 22 is located right above the first hook 12 .

[0028]As a furt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com