Injecting frame of injection molding machine

An injection molding machine and frame technology, which is applied in the field of injection molding machine injection frame, can solve the problems of wear of the rolling screw, inability to meet the installation requirements of double oil cylinders, etc., and achieves the effects of prolonging the service life, simple structure and reducing the connection distance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific examples.

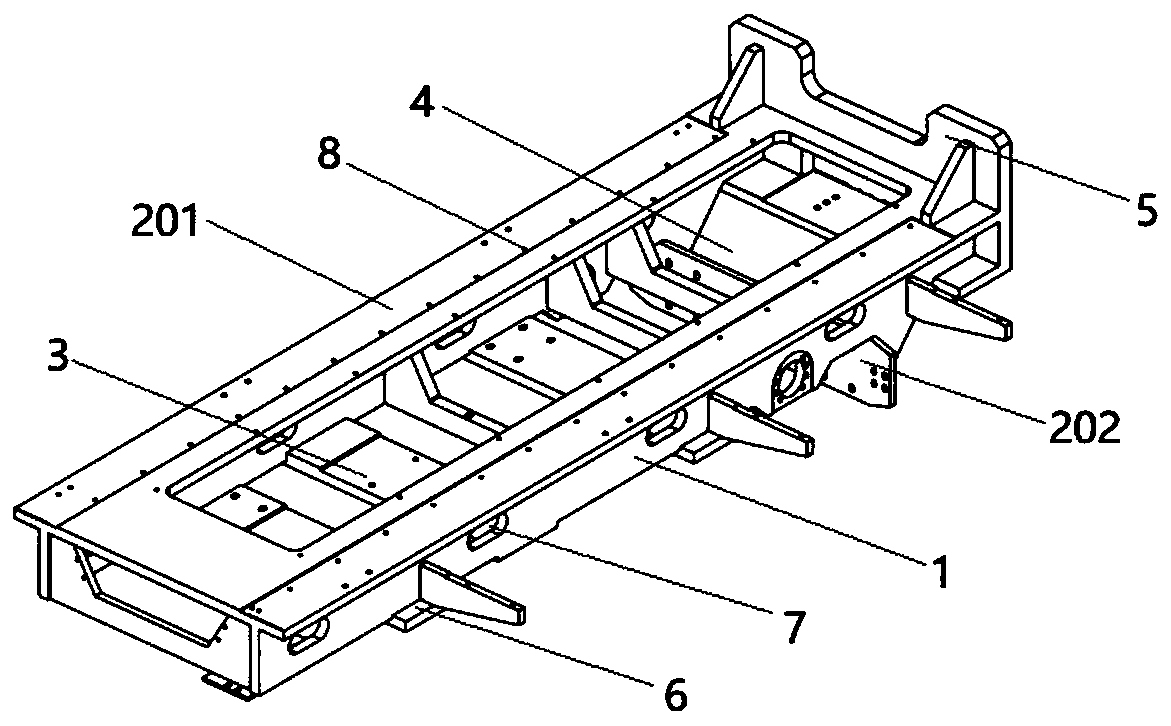

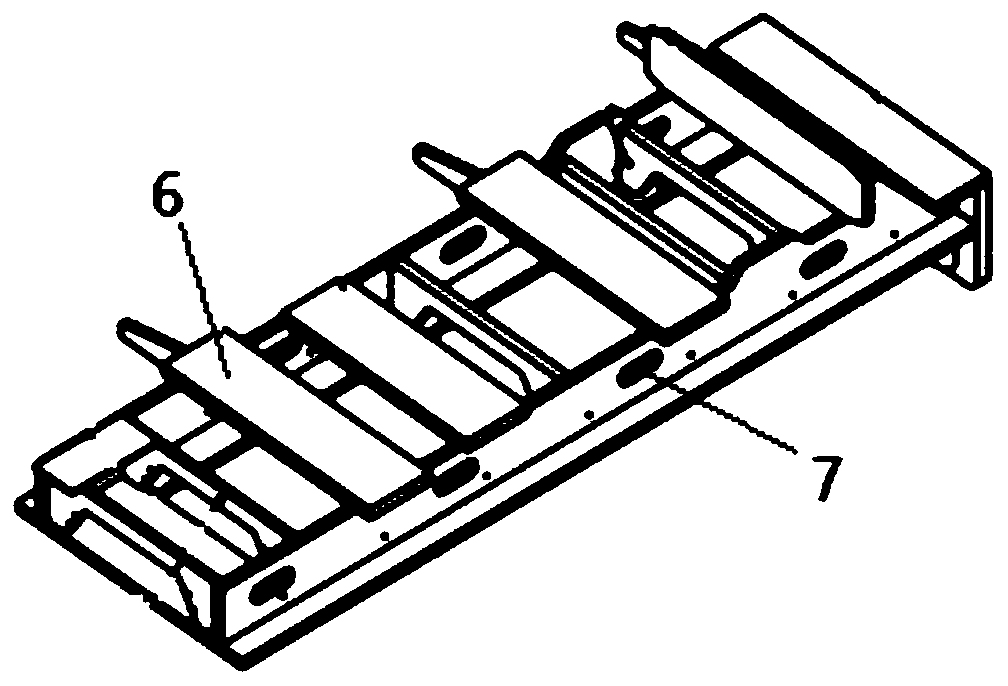

[0016] according to Figure 1 ~ Figure 2 , the present invention provides an injection frame for an injection molding machine, which includes a main body 1, a linear track mounting plate, a motor mounting seat 3, and a rolling screw mounting seat 4. The linear track mounting plate is divided into a longitudinal track mounting plate 201 and a transverse track mounting plate 202, the longitudinal rail mounting plate 201 is installed on the upper surface of the main body 1, the transverse rail mounting plate 202 is installed on the bottom side of the main body 1, and the rolling screw mounting seat 4 is arranged on the main body 1 The inner side is located on the upper part of the transverse rail mounting plate 202 , and the motor mounting base 3 is installed on the other s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com