Braking device and method of mechanically driven road roller

A technology of mechanical drive and braking device, which is applied in the direction of foot-operated starting device, braking transmission device, mechanical control, etc., and can solve the problems of being unable to cut off the power and prone to danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

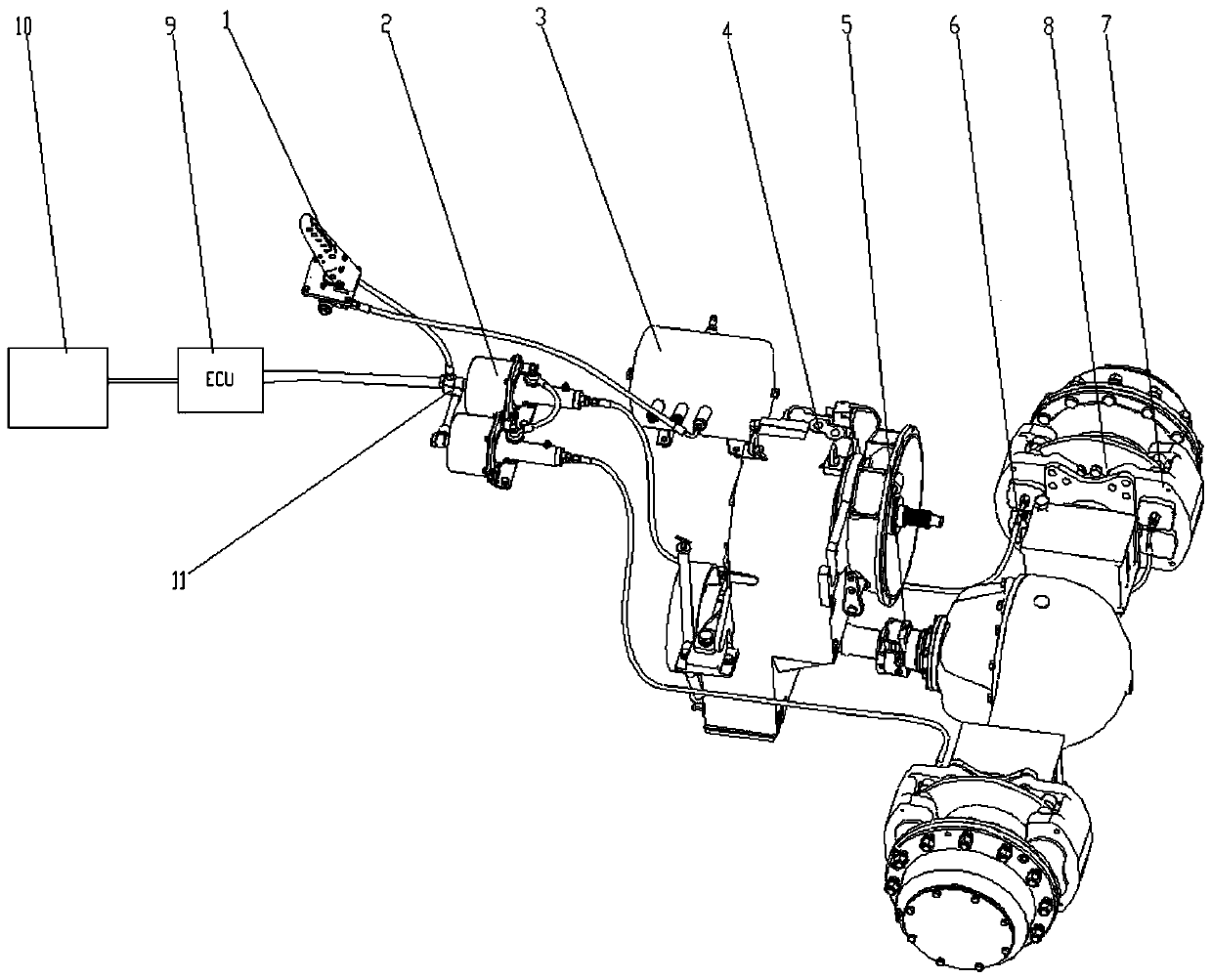

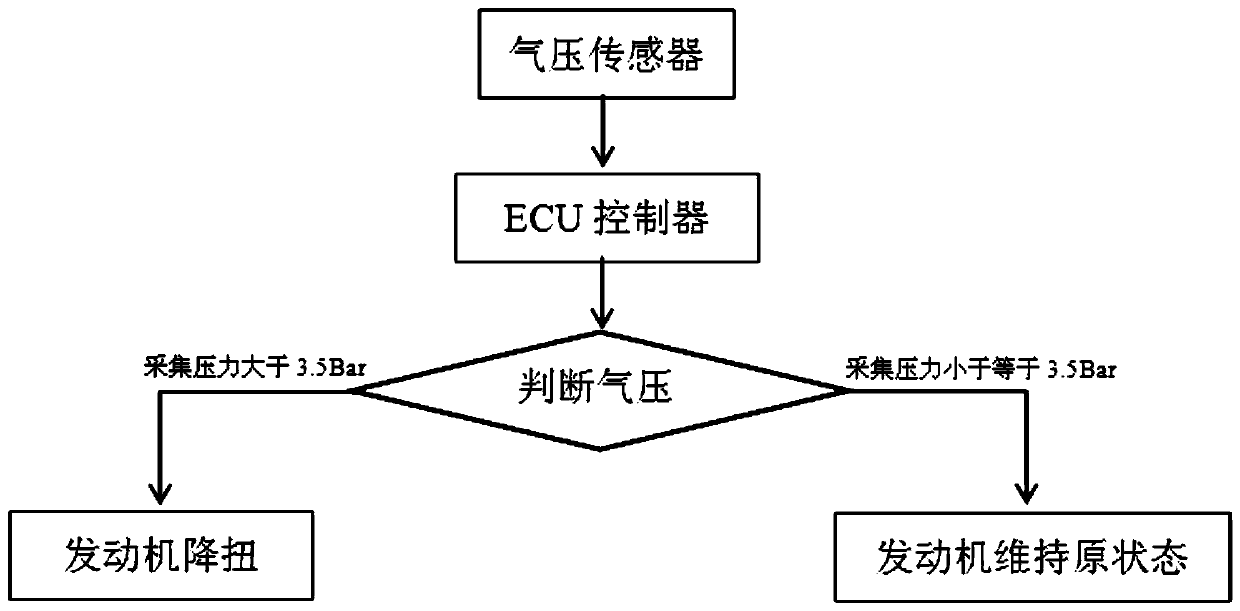

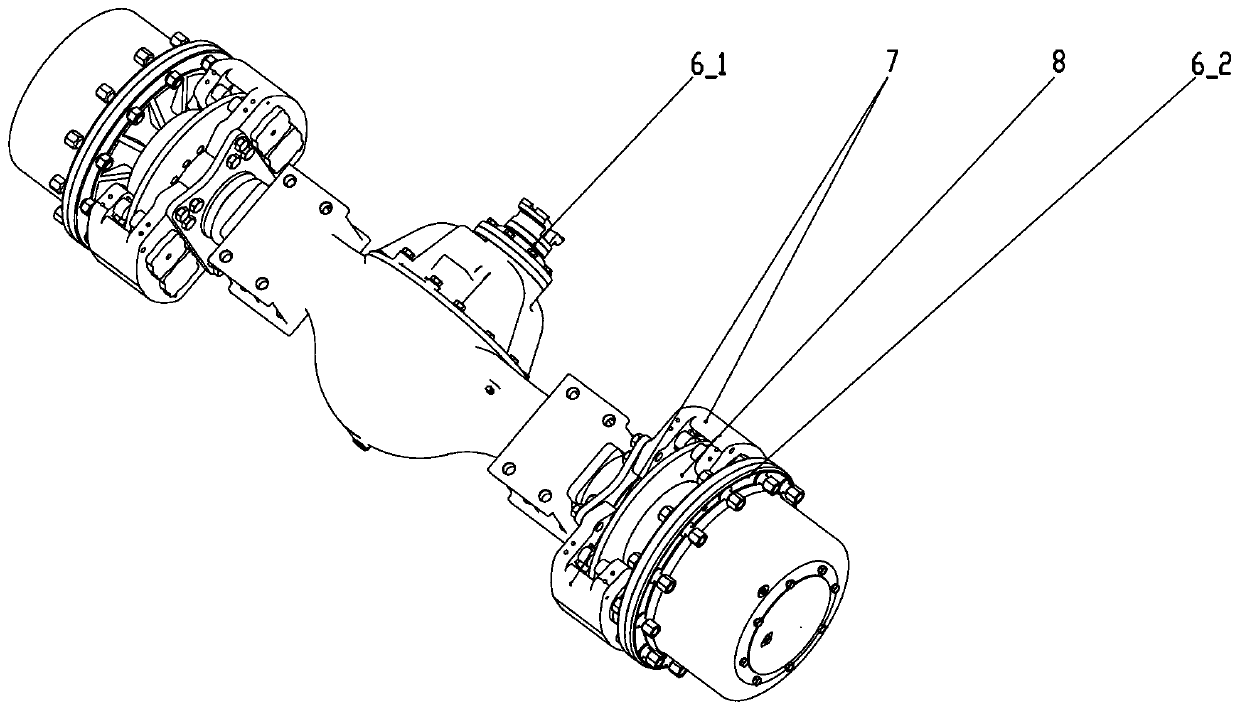

[0028] Such as figure 1 and image 3 As shown, the brake pedal 1, the air booster pump 2, the air bag 3, the mechanical gearbox 4, the drive axle 6, the ECU controller 9, and the engine 10 are installed in the appropriate parts of the mechanically driven road roller, and the transmission shaft 5 is connected to the mechanical gearbox 4 The output terminal of the driving bridge 6 and the driving bridge input terminal 6_1 of the driving bridge 6 . Brake disc 8 is welded as one with wheel edge mounting disc 6_2, and when transaxle input end 6_1 has rotational torque input, brake disc 8 and wheel limit mounting disc 6_2 rotate synchronously. Brake 7 is fixed on the drive axle 6 wheel housings by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com