Wine making device

A technology for a wine making device and a fermentation device, which is applied in the preparation of alcoholic beverages and other directions, can solve the problems of poor thermal insulation performance, large heat loss, poor sealing performance, etc., and achieve the effects of excellent performance, diverse functions and strong practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0022] In conjunction with the accompanying drawings, the present invention is described in detail.

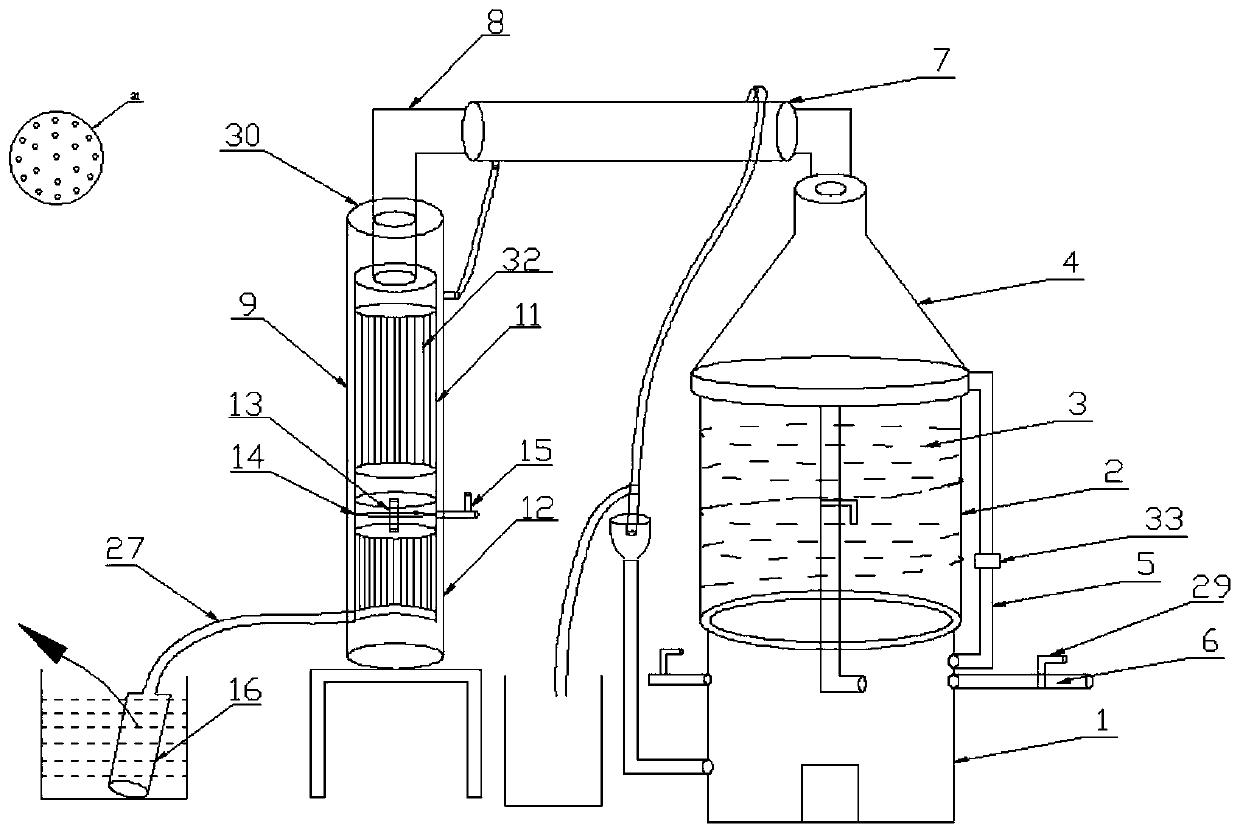

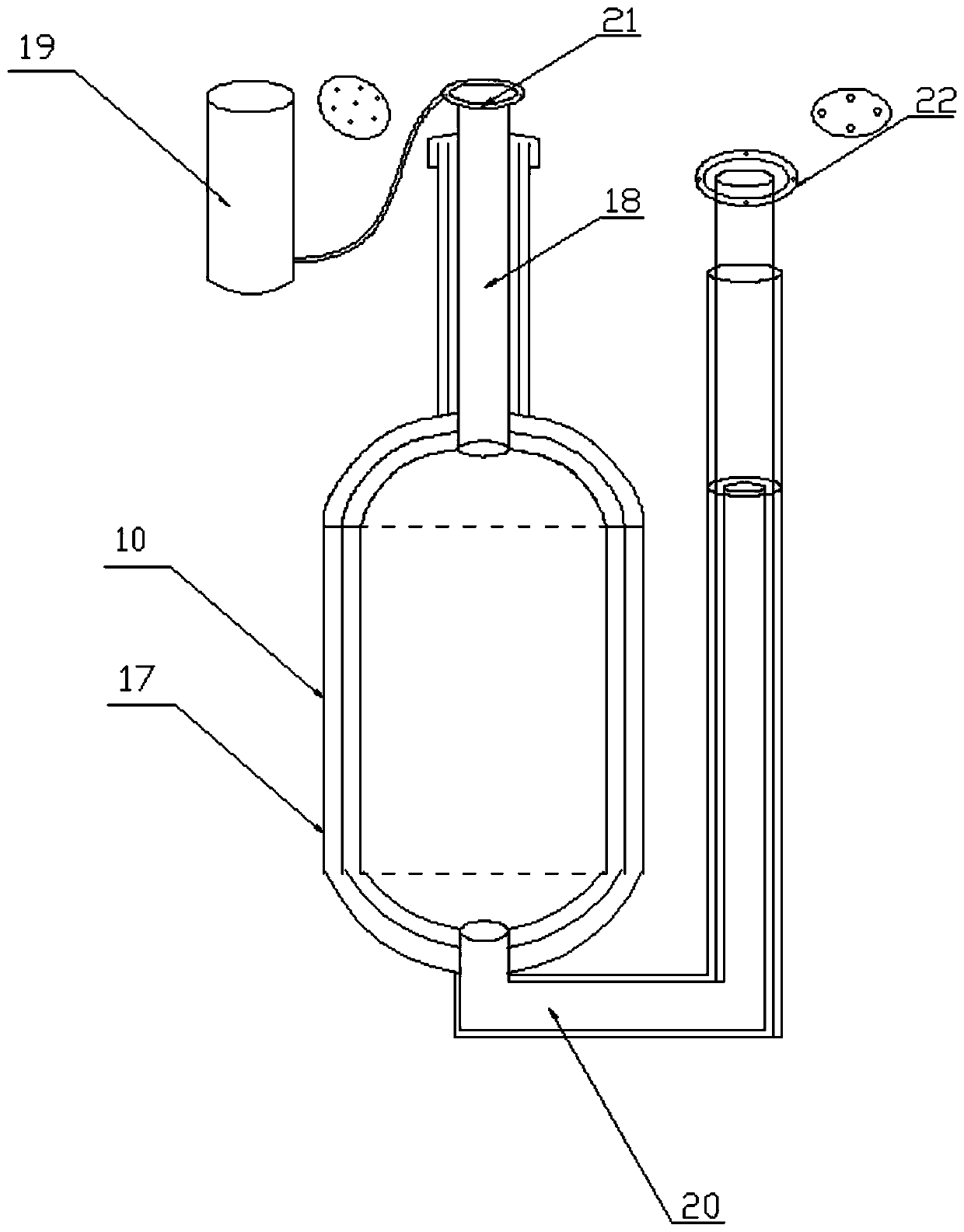

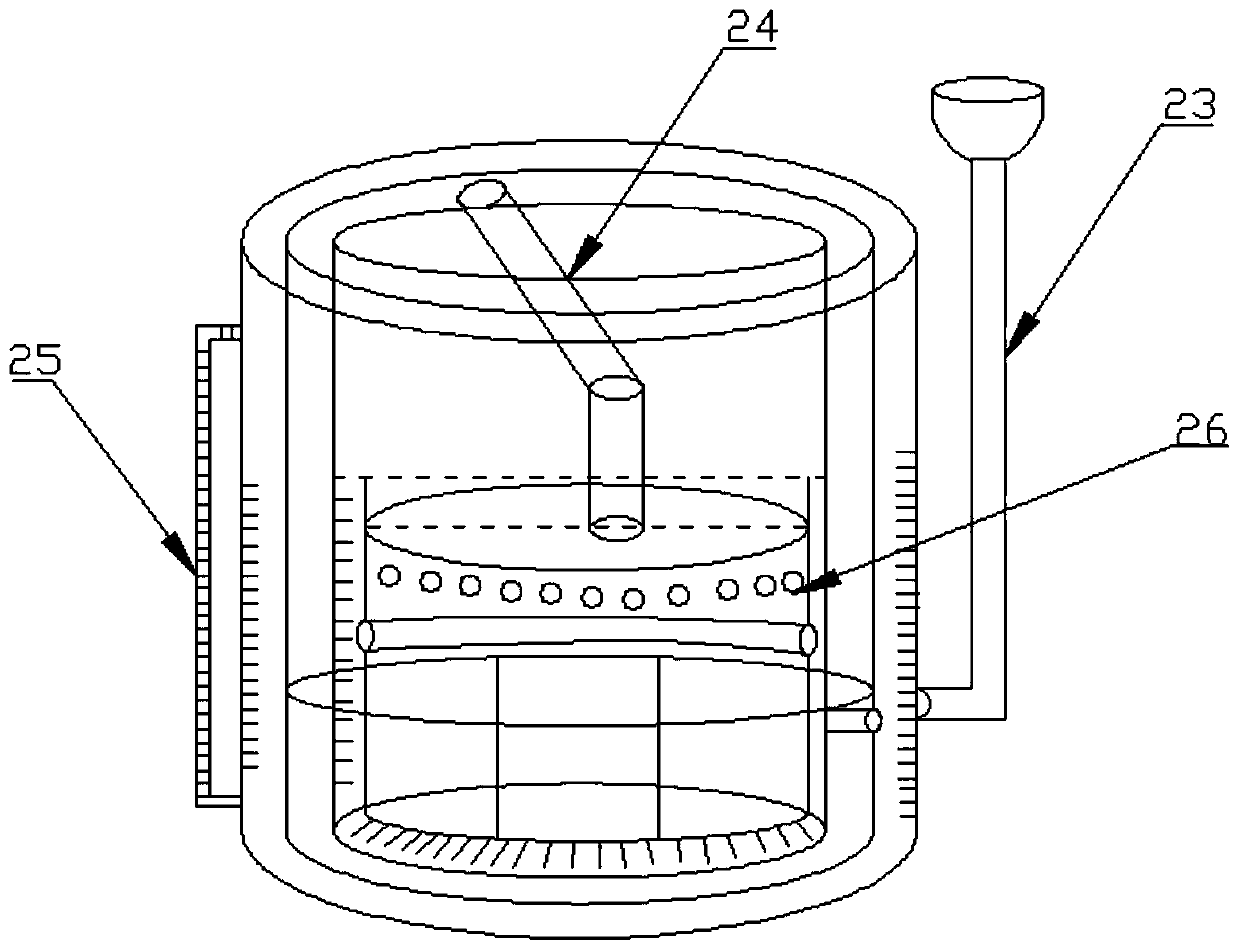

[0023] The present invention provides a wine making device during specific implementation, comprising a steam boiler 1, a wine steamer 2 and a fermentation device 10, the wine steamer 2 is arranged above the steam boiler 1, the steam boiler 1 and the wine steamer A gas pipe 5 is arranged between the outer walls of the device 2, the top of the gas pipe 5 communicates with the wine distiller 2, the bottom of the gas pipe 5 communicates with the steam boiler 1, and the inner wall of the wine distiller 2 is provided with a suction pipe. A heat pipe 3, a wine still cover 4 is provided above the wine still 2, a steam outlet 6 is provided below the gas delivery pipe 5 for discharging excess steam, and a steam outlet 6 is provided for cooling The steam cooling pipe ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap