A top closed steel pipe pile

A steel pipe pile, closed-end technology, applied in the direction of sheet pile wall, building, foundation structure engineering, etc., can solve the problem of low bearing capacity, achieve stability, improve vertical pull-out bearing capacity, and reduce engineering costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further illustrated below in conjunction with specific embodiments, and it should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

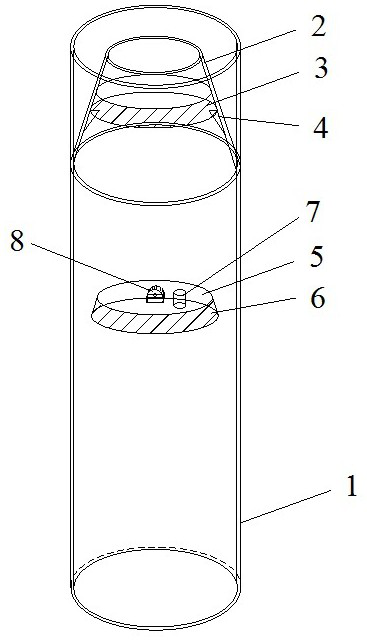

[0015] Such as figure 1 As shown, a top closed-end steel pipe pile of this embodiment includes a steel pipe pile body 1 and a top cover 5, and a truncated circular steel pipe 2 is built in the upper part of the pipe pile body 1, and the truncated circular steel pipe 2 The bottom edge is welded on the inner side of the pipe pile body 1, and the inner side of the truncated conical steel pipe 2 is provided with a ring of built-in rubber ring 3, and the inner side of the truncated conical steel pipe 2 is located below the built-in rubber ring 3 and is provided with an elastic clip. Fastener 4, the top cover 5 is in the shape of a truncated cone and the angle between the generatrix of the top cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com