Cast-in-place gravity-suction-type caisson foundation

A caisson foundation and suction technology, which is applied in infrastructure engineering, protection devices, buildings, etc., can solve problems that threaten the safety of the upper structure, large horizontal and vertical bearing capacity, etc., to ensure stability and improve pullout bearing capacity , The effect of improving engineering efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

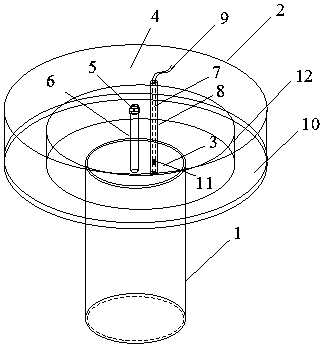

[0025] Embodiment 1: as figure 1 Shown: the diameter of the bucket compartment 2 is greater than the diameter of the suction caisson foundation 1 . The inside of the barrel cabin 2 can be used for pouring concrete weights 4 and also for riprap. When used for riprap, the top of the cover 3 is not provided with a connecting steel bar 12 . The bottom of the barrel compartment 2 is provided with a bottom plate 10; the bottom plate 10 is welded and fixed to the cover 3;

Embodiment 2

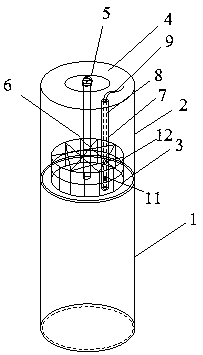

[0026] Embodiment 2: as figure 2 Shown: the diameter of the bucket compartment 2 is equal to the diameter of the suction caisson foundation 1 . The interior of the barrel compartment 2 can be used for pouring concrete weights 4 or for riprap, and when used for riprap, the top of the cover 3 is not provided with a connecting steel bar 12;

[0027] The construction sequence of the cast-in-situ gravity suction caisson foundation in the above embodiment: 1. The caisson sinks under negative pressure; 2. After the caisson is installed, concrete is poured underwater or rocks are poured underwater.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com