Novel grouting type gravity anchor pile foundation suitable for medium water depth

A pile foundation and gravity anchor technology, which is applied in the field of new grouting gravity anchor pile foundation, can solve the problems of construction, engineering cost adverse effects, increasing the length of anchor piles, etc., so as to achieve easy control of construction quality and increase vertical resistance The effect of pull-out bearing capacity and great construction flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing.

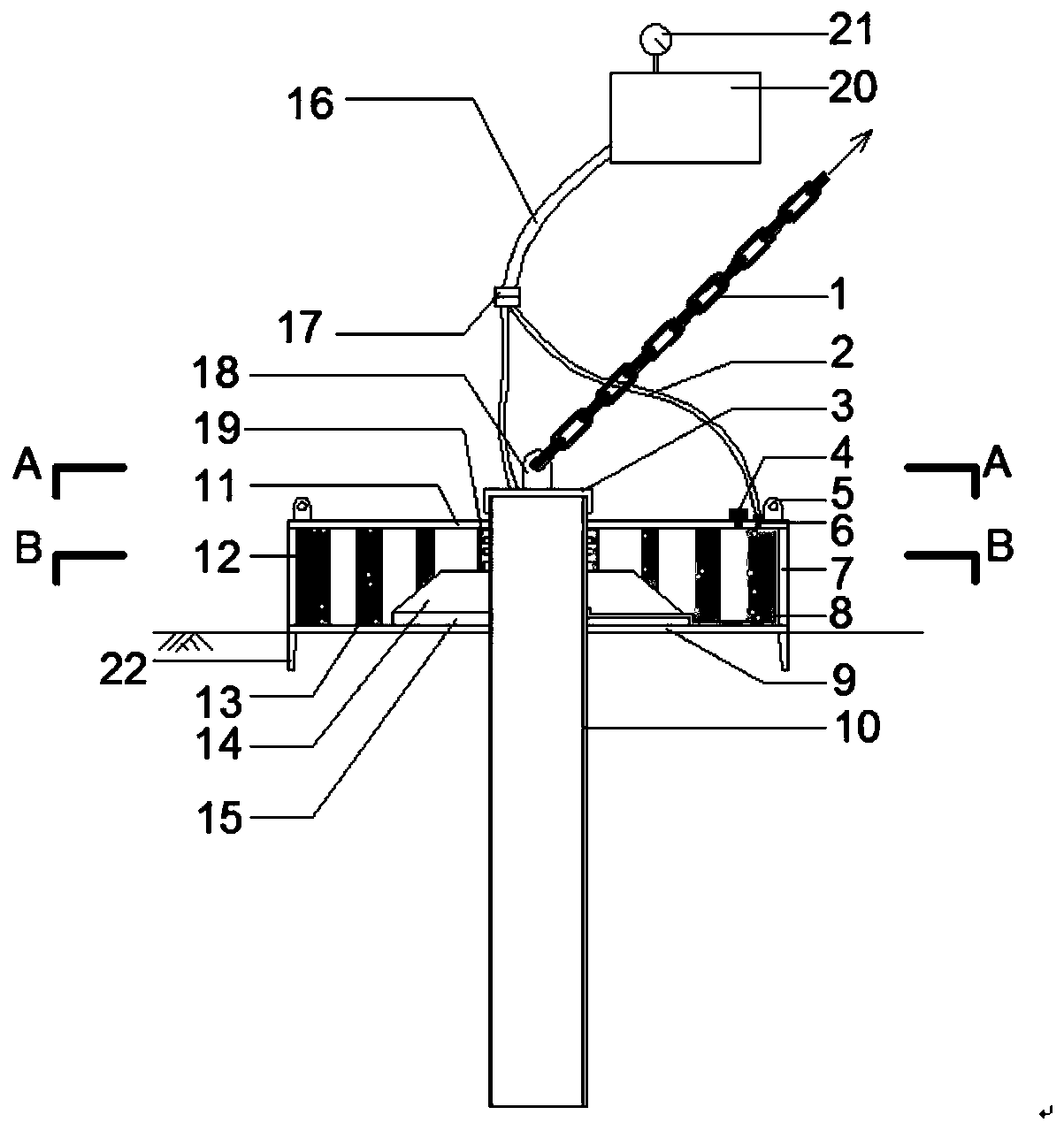

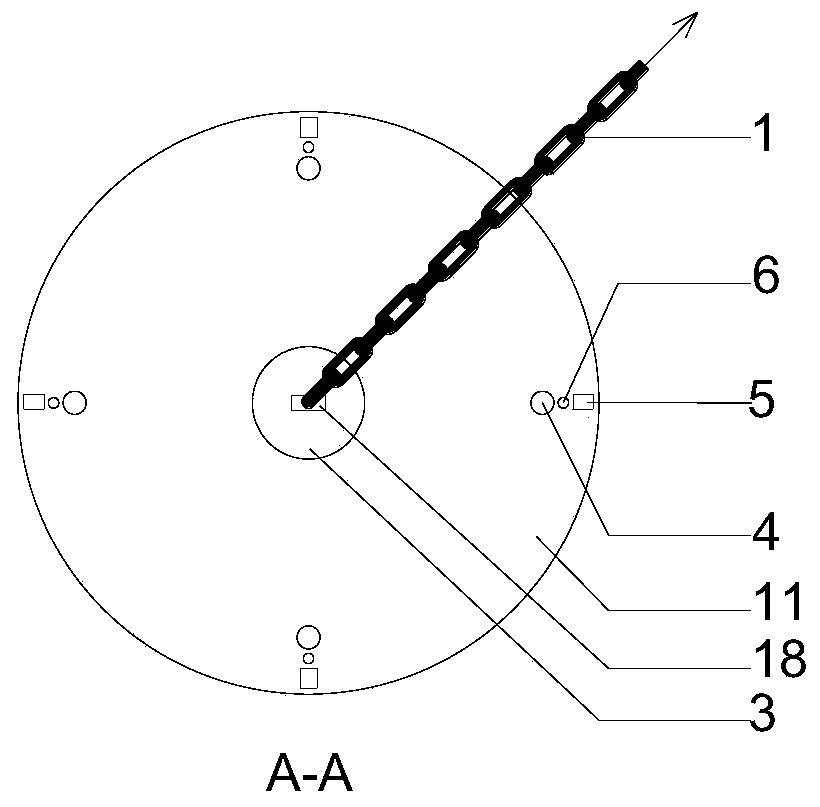

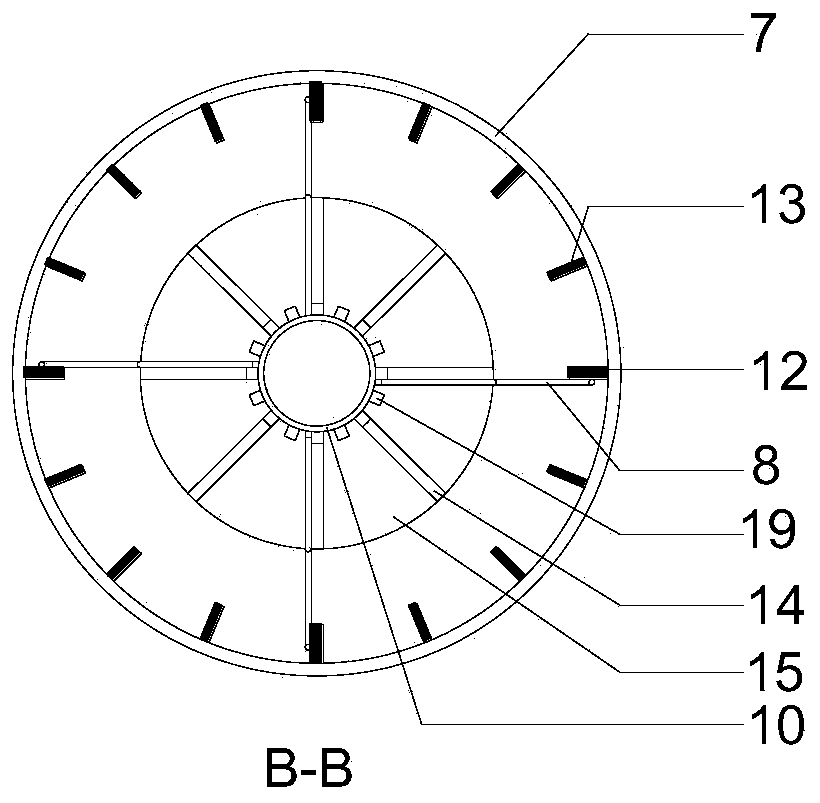

[0024] Such as Figure 1 to Figure 3 As shown, the present invention includes a mooring cable 1, a grouting hose 2, a pile cap 3, a pressure relief valve 4, a suspension ring 5, a connecting bolt 6, a side wall 7, a grouting inner pipe 8, a bottom plate 9, and a steel pipe pile 10 , top plate 11, thick vertical plate 12, thin vertical plate 13, reinforcement plate 14, pile plate 15, slurry pipe 16, transfer plate 17, mooring ring 18, shear key 19, grouting machine 20, pressure gauge 21 and Skirt 22. Such as figure 1 As shown, the side wall 7, the bottom plate 9 and the top plate 11 jointly form a cylindrical gravity chamber, the top plate 11 and the bottom plate 9 are made of steel circular plates, and the side wall 7 is circular, and they are welded together to form a cylindrical gravity chamber . Wherein, the center of top plate 11 and bottom plate 9 is reserved to be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com