A self-priming pump water pipe connection structure

A connection structure, self-priming pump technology, applied in the direction of pipeline connection layout, flange connection, pipe/pipe joint/pipe fittings, etc., can solve the problems of troublesome connection, poor adaptability of self-priming pump, etc., to achieve convenient connection and reduce rust Dead, compacted effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

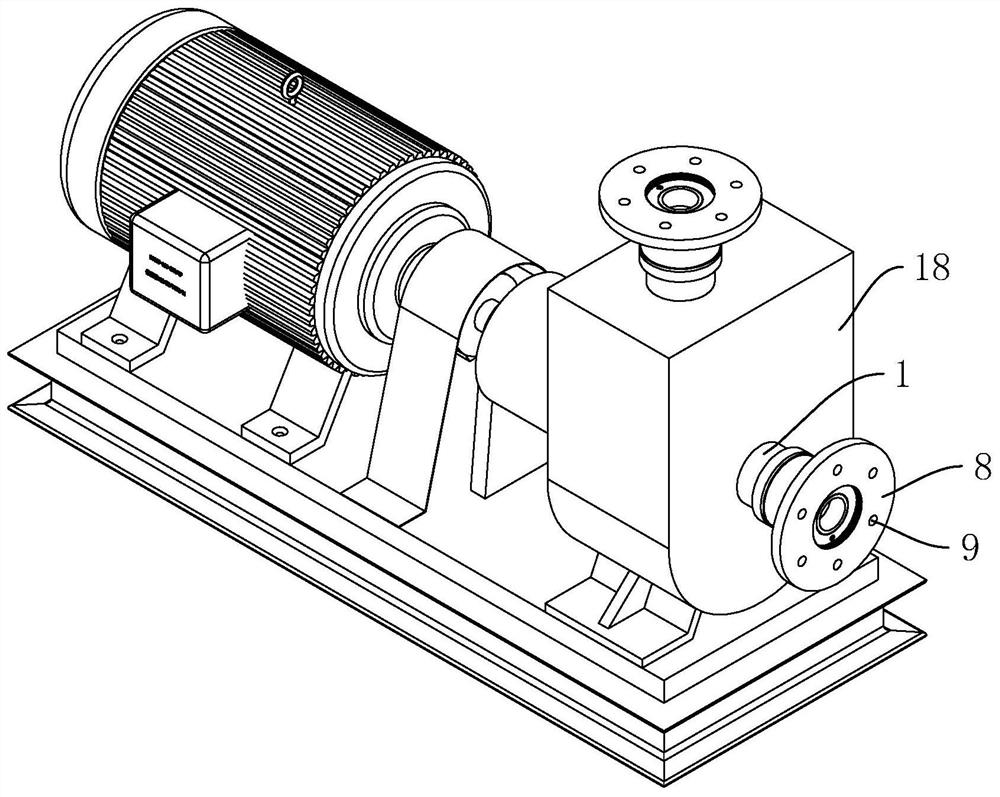

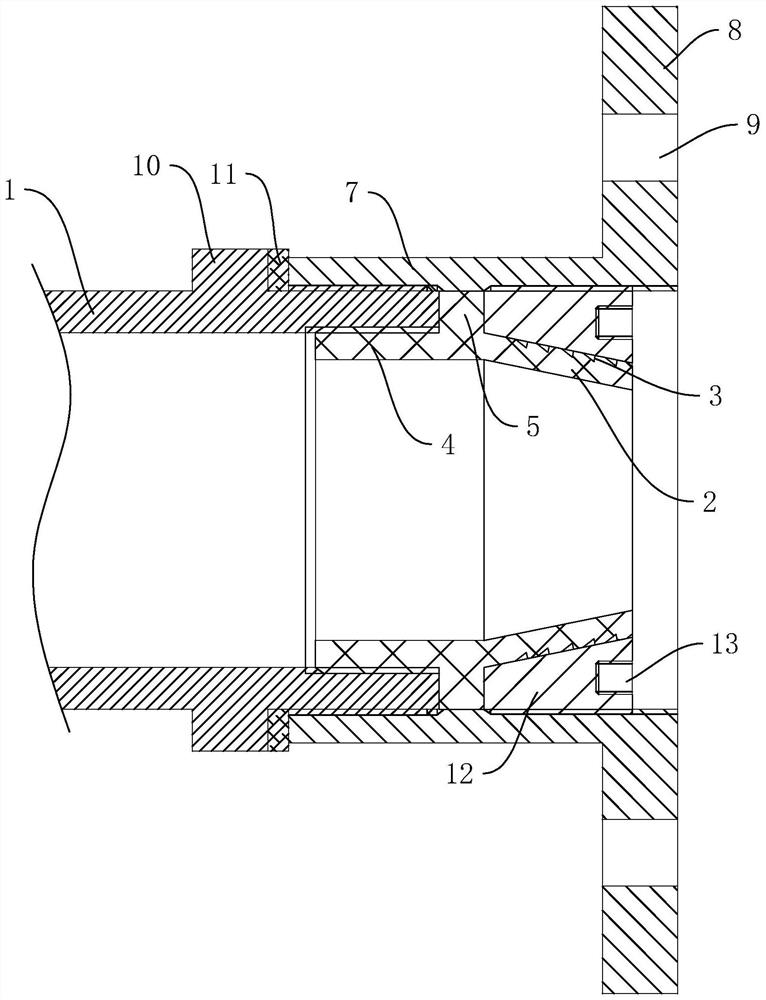

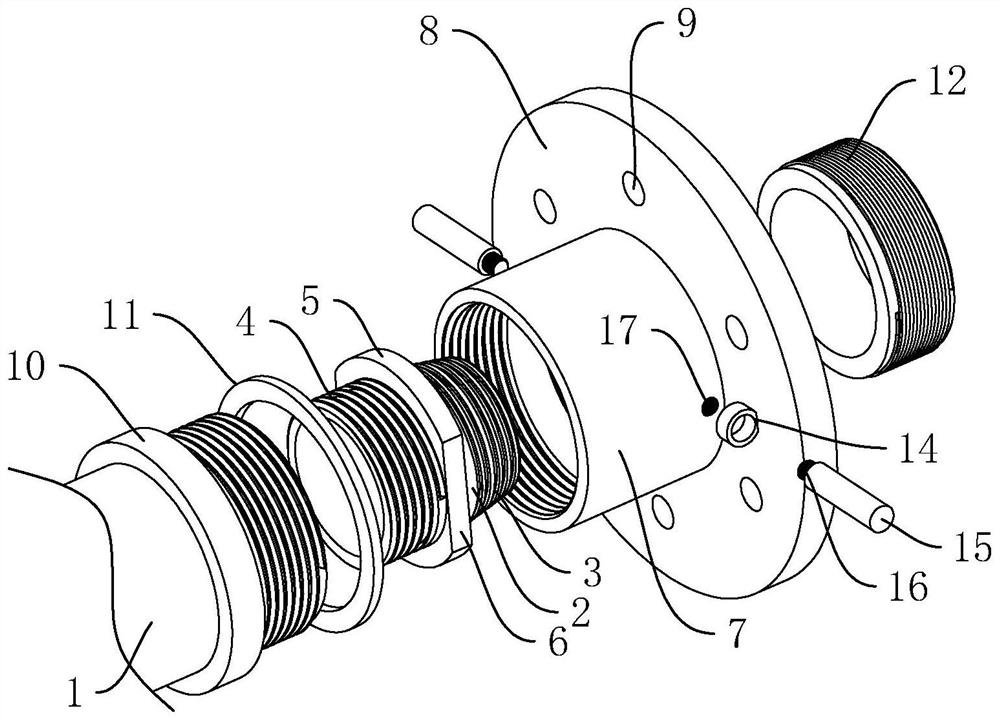

[0037] A self-priming pump water pipe connection structure, such as figure 1 , figure 2 As shown, it includes a pipeline 1 arranged on the water inlet or outlet of the pump body 18 of the self-priming pump. The end of the pipeline 1 away from the pump body 18 is connected with a connecting pipe 2, and the diameter of the connecting pipe 2 is smaller than that of the pipeline 1. set up. The pipe diameter of the connecting pipe 2 is constricted toward the direction away from the pump body 18, and the outer wall of the connecting pipe 2 is also provided with several anti-slip grooves 3 along the axial direction. When the pipeline 1 needs to be connected with a water pipe, the connecting pipe 2 can be used for socketing the water pipe.

[0038] Such as figure 2 , image 3 As shown, the end of the connecting pipe 2 close to the pipeline 1 is also provided with a connecting section 4 threadedly connected with the pipeline 1, the outer wall of the connecting section 4 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com