Non-destructive testing system and method for pre-stressed concrete beams

A technology for non-destructive testing of concrete beams, which is applied to measuring devices, material inspection products, and the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc. Stressed concrete beam detection and other problems, to achieve the effect of high qualitative detection efficiency, easy and accurate judgment, and short detection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

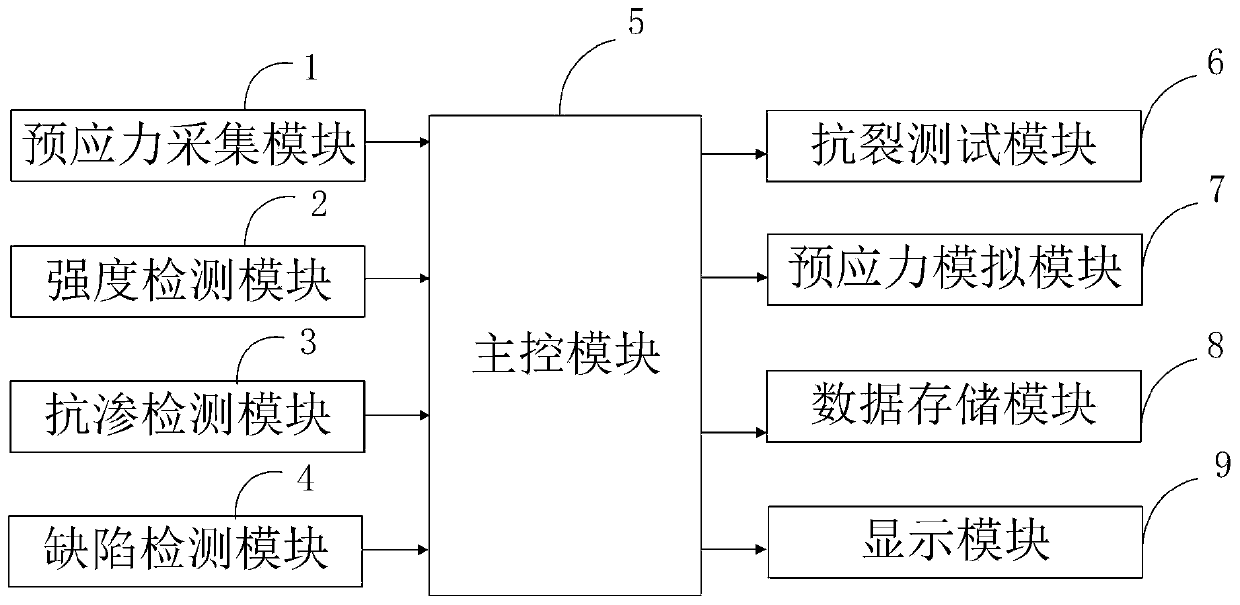

[0051] In order to further understand the content, features and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings.

[0052] The structure of the present invention will be described in detail below in conjunction with the accompanying drawings.

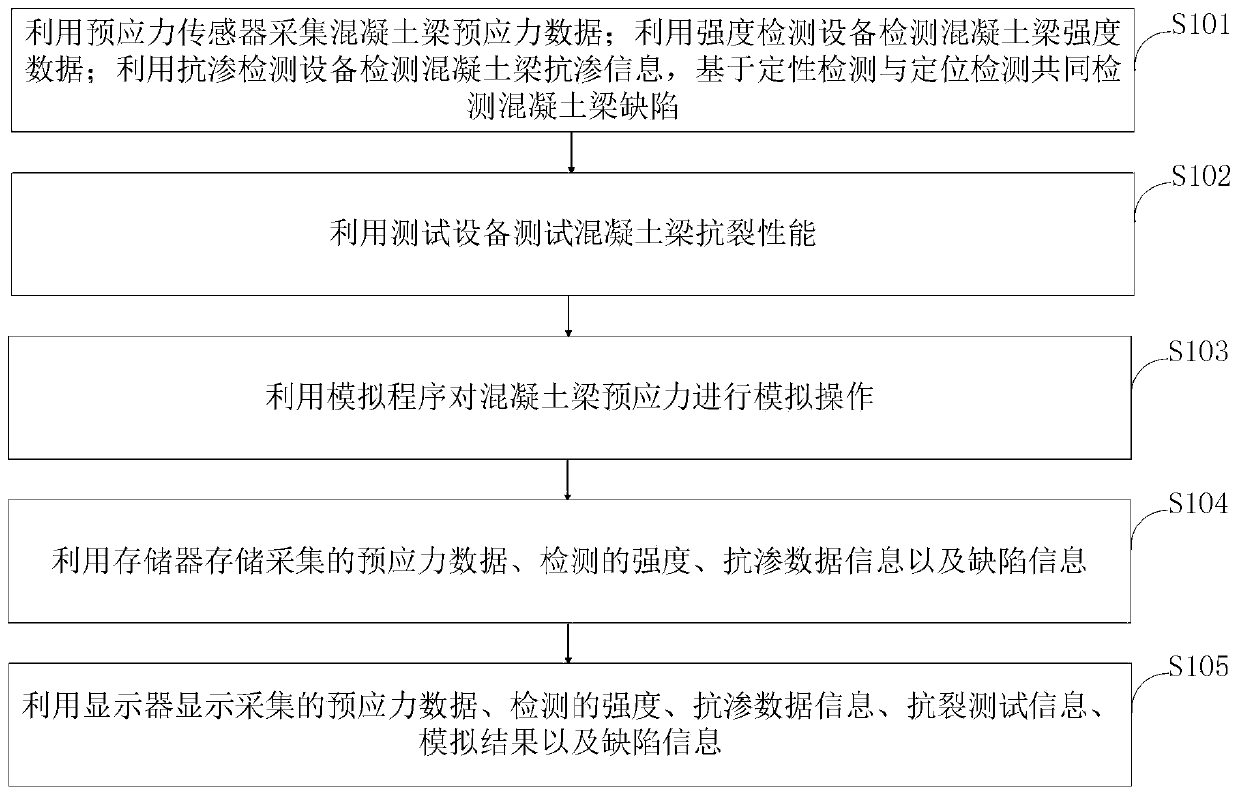

[0053] Such as figure 1 As shown, the non-destructive testing method for prestressed concrete beams provided by the embodiments of the present invention includes the following steps:

[0054] Step S101, using the prestress sensor to collect the prestress data of the concrete beam; using the strength detection equipment to detect the strength data of the concrete beam; using the anti-seepage detection equipment to detect the anti-seepage information of the concrete beam, and jointly detecting the defects of the concrete beam based on qualitative detection and positioning detection;

[0055] Step S102, using testing equipment to test ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com