Rainwater cooling device for on-pole transformer

A technology of a cooling device and a transformer, which is applied in the field of transformer cooling, can solve problems such as unsuitable pole-mounted transformers, and achieve the effects of low cost, reduced heating, and good cooling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

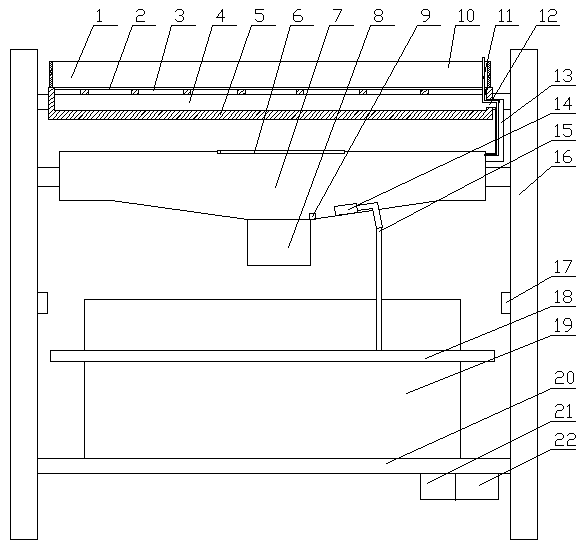

[0027] Embodiment 1. This embodiment provides a pole-mounted transformer rainwater cooling device, including a utility pole 16 and a platform main body 20 arranged on the utility pole 16. A transformer 19 is arranged on the platform main body 20. The utility pole 16 is A water collecting mechanism is arranged above the transformer 19, a water storage mechanism is arranged below the water collecting mechanism, a spray cooling mechanism connected to it is arranged below the water storage mechanism, a filtering mechanism is arranged above the water collecting mechanism, and the A control mechanism 21 connected to the water storage mechanism is arranged under the platform body 20 , and the control mechanism 21 is connected to the control center through a communication mechanism 22 .

[0028] The water collection mechanism includes a water collection plate 5 provided on the utility pole 16, the upper surface of the water collection plate 5 is provided with a water collection pit 4, ...

Embodiment 2

[0031] The difference between this embodiment and Embodiment 1 is:

[0032] The water storage mechanism includes a water storage tank 7 arranged below the water collecting plate 5, the water storage tank 7 is a rectangular structure, the inside of the water storage tank 7 communicates with the first pipeline 13, and the first A pressure regulating pipe 11 is arranged in the pipeline 13 , the lower end of the pressure regulating pipe 11 communicates with the inside of the water storage tank 7 , and the height of the upper end of the pressure regulating pipe 11 is greater than the height of the water collecting plate 5 . The water storage tank can be set in a flat structure, but the water storage tank has no other mechanism to communicate with the outside except the first pipe, so a pressure regulating pipe needs to be installed, otherwise the water enters from the first pipe, and the internal gas cannot be discharged, and it will As a result, the internal air pressure is relati...

Embodiment 3

[0036] The difference between this embodiment and Embodiment 1 is:

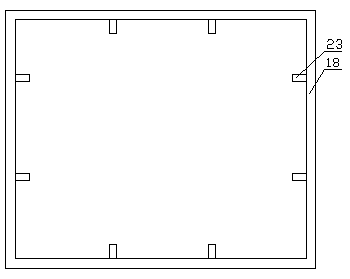

[0037] The spray cooling mechanism includes a ring of pressure pipes 18 arranged around the transformer 19, the inner side of the pressure pipe 18 is provided with an atomizing nozzle 23 communicating with the pressure pipe 18, and the pressure pipe 18 is connected to the pressurized water pump through the second pipe 15 14 connected. The pressurized water pump pressurizes the water into the pressure pipe, and the water is sprayed from the atomizing nozzle through the pressure to spray and cool the surface of the transformer. The atomized spray is used to make the watering more uniform and save water.

[0038] The filter mechanism includes a support frame 3 provided on the water collection plate 5 at the upper end of the water collection pit 4, a filter screen 2 is arranged on the support frame 3, and a water retaining plate 5 extends upwards along the edge of the water collection plate 5. plate 1. The filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com