Electrified railway in-phase traction power supply system and control method thereof

A traction power supply system, electrified railway technology, applied in the direction of reducing/preventing power oscillation, AC network load balancing, single-network parallel feeding arrangement, etc. , traction network and on-board equipment burning and other problems, to achieve the effect of improving flexibility, easy to compensate for capacity expansion, and superior performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

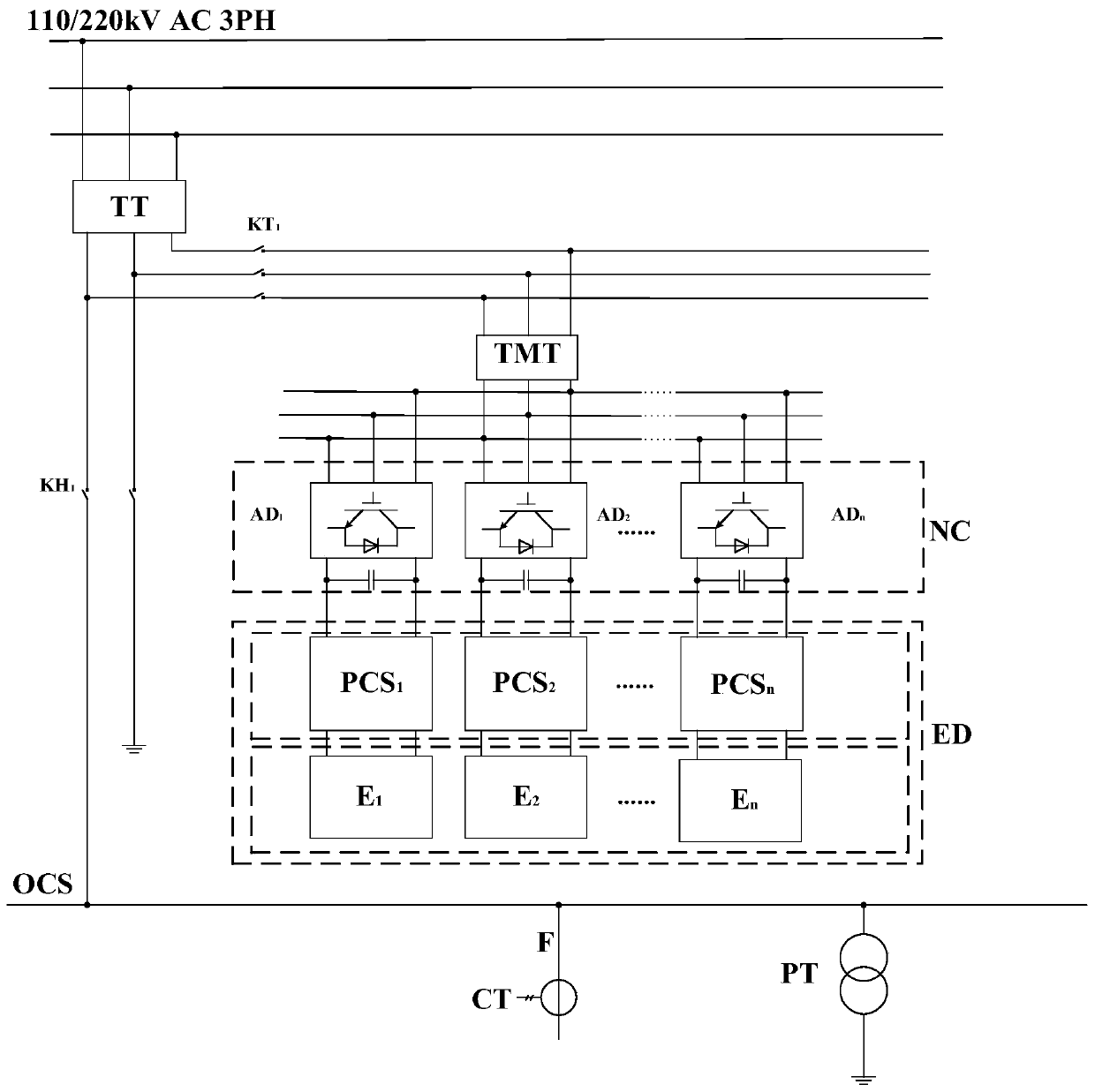

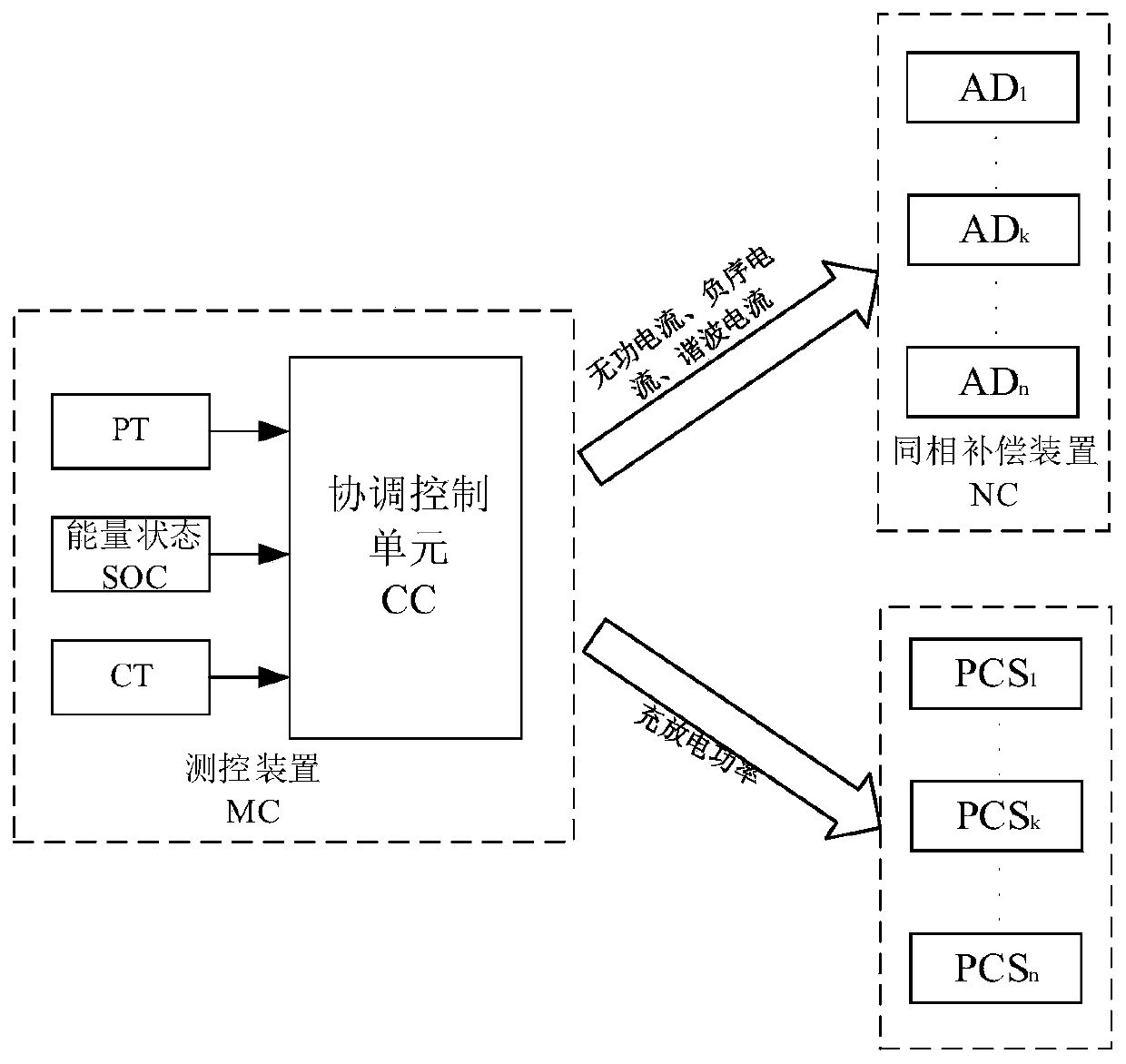

[0047] like figure 1 As shown, the embodiment of the present invention provides an electrified railway in-phase traction power supply system, wherein the in-phase traction power supply system includes a traction transformer TT for transforming the line voltage of the three-phase high-voltage bus to the traction bus OCS, for The compensation matching transformer TMT for the energy conversion of the traction transformer TT, the in-phase compensation device NC for power quality compensation of the in-phase traction power supply system, the energy storage device ED for storing electric energy and controlling charging and discharging, and for detecting the Active power positive and negative, magnitude of voltage and current, coordination of real-time charge and discharge of energy storage device ED and measurement and control device MC of power quality compensation of non-phase compensation device NC. The primary side of the traction transformer TT is connected to the three-phase h...

Embodiment 2

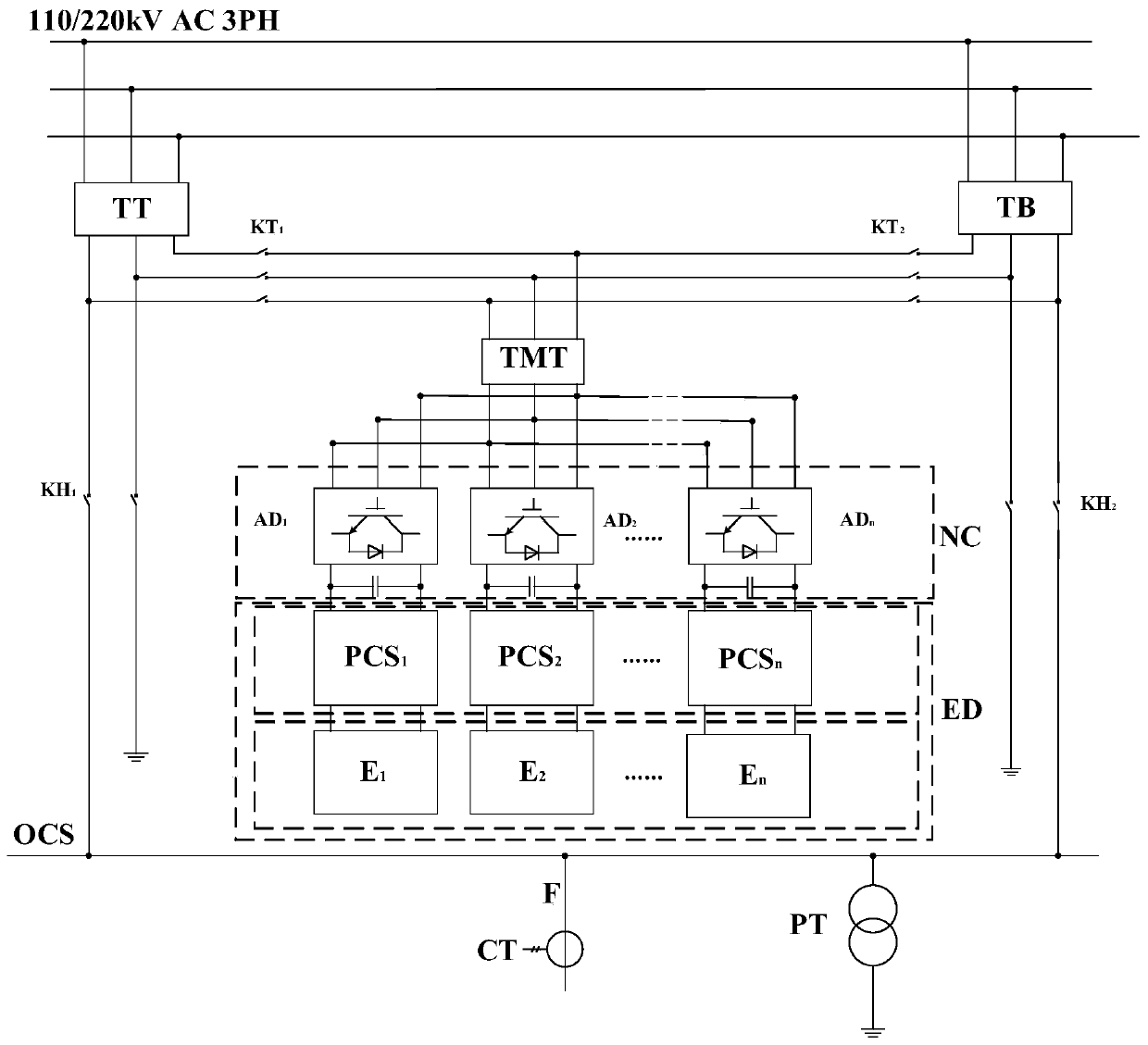

[0054] like image 3 As shown, the embodiment of the present invention provides an electrified railway in-phase traction power supply system. The main difference from the embodiment of the present invention is that the in-phase traction power supply system also includes a device for converting the line voltage of the three-phase high-voltage bus to the traction bus. A standby traction transformer TB, the primary side of the standby traction transformer TB is connected to the three-phase high-voltage bus, and any two terminals of the secondary side are connected to the traction load; the secondary side of the standby traction transformer TB passes through the second circuit breaker KT 2 It is connected with the primary side of the compensation matching transformer TMT. Other technical features are completely the same as those in Embodiment 1 of the present invention, and will not be repeated here.

[0055] Generally, under normal conditions, the traction transformer TT, the co...

Embodiment 3

[0057] like Figure 4 and Figure 5 As shown, the embodiment of the present invention provides a control method of the same-phase traction power supply system for electrified railways, wherein the specific steps of the control method include charging and discharging of the energy storage device ED and power quality compensation of the same-phase compensation device NC, wherein, The specific steps of the control method of the power quality compensation of the in-phase compensation device NC are:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com