High performance voltage controllable electrical power supply

A power supply, high-performance technology, applied in current collectors, battery circuit devices, electric vehicles, etc., to achieve the effect of ensuring normal use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

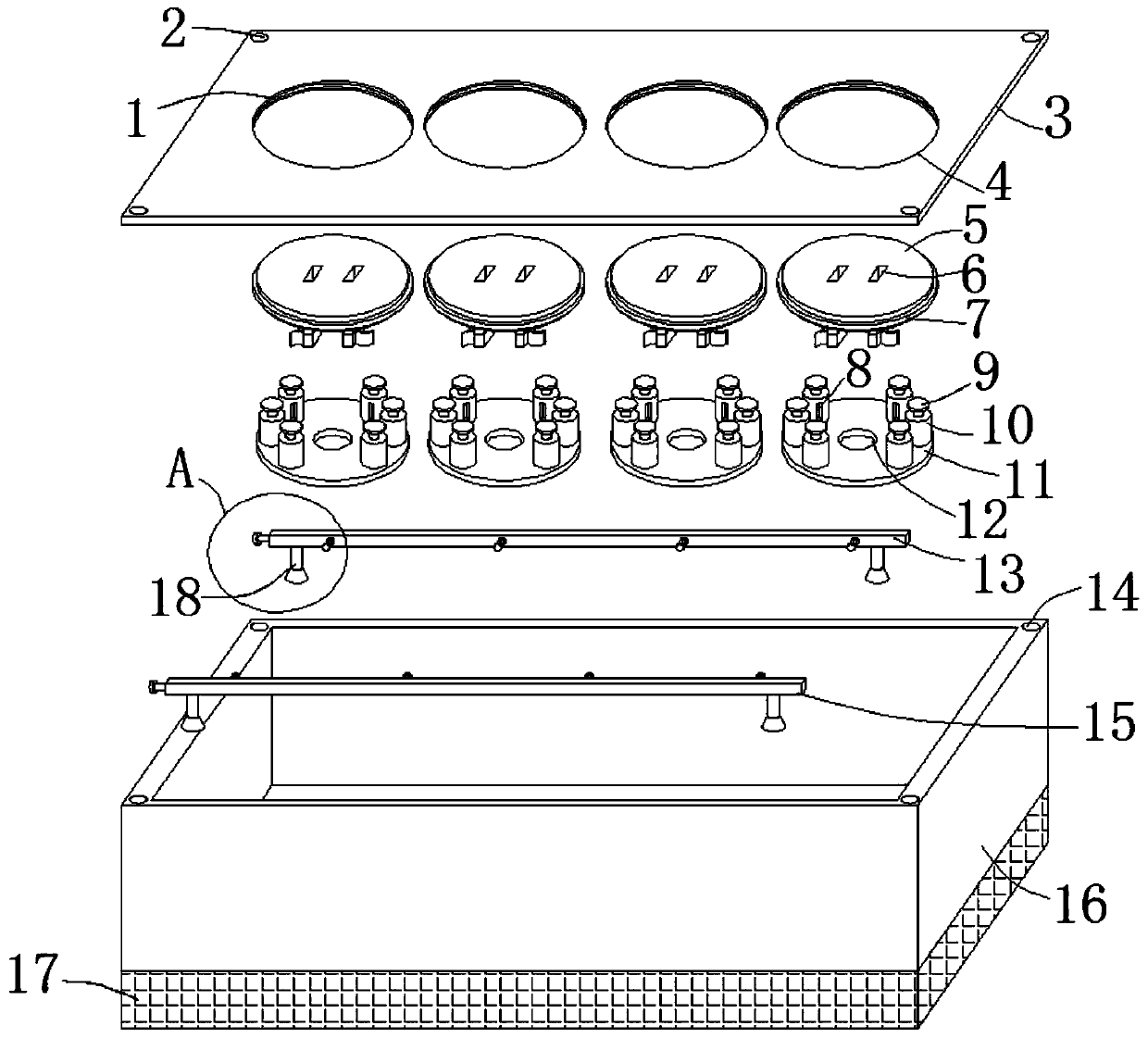

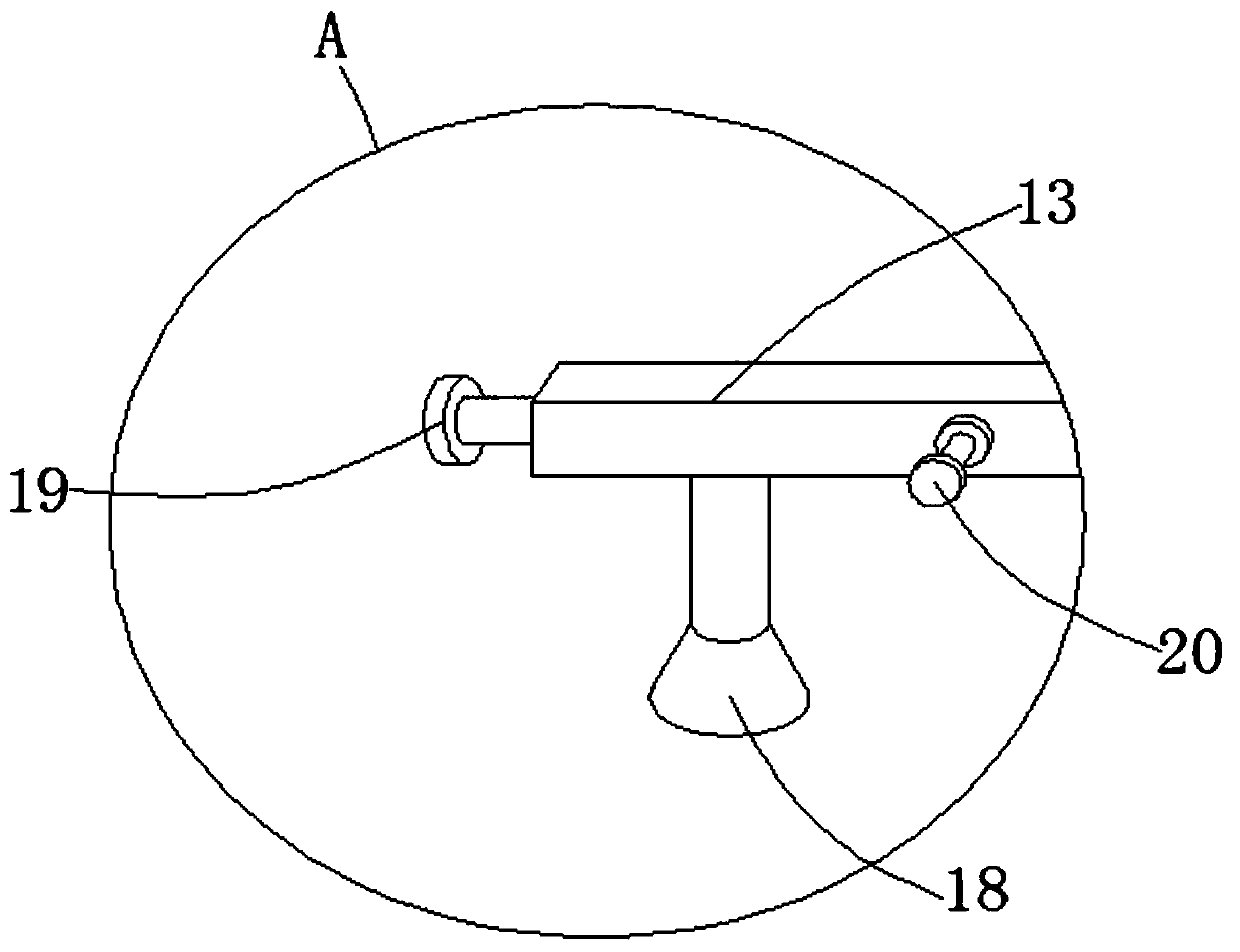

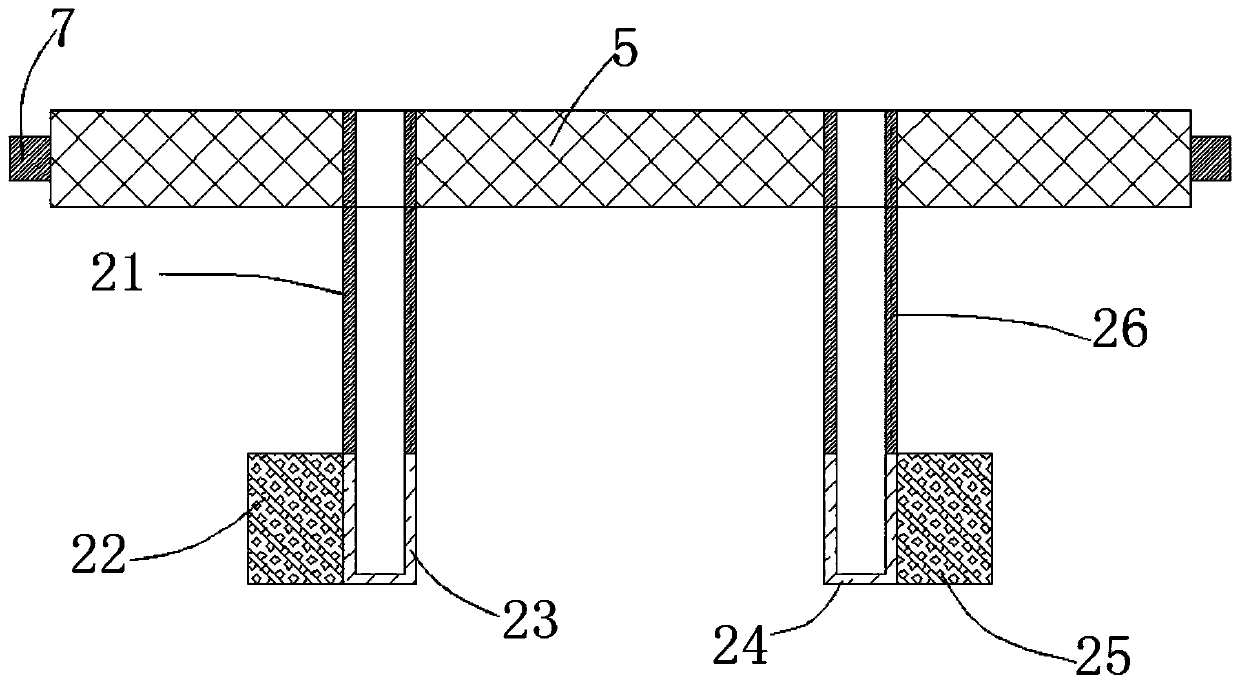

[0020] see Figure 1-3 , this embodiment provides a high-performance voltage-controllable electrical power supply, including a housing 16, an upper cover 3, several sockets 5 and several insulating mounting plates 11, the inner cavity of the housing 16 is a hollow structure, The upper cover 3 is located directly above the shell 16 and is matched with each other. The upper cover 3 is provided with several circular openings 4, and the inner chamber side walls of the several circular openings 4 are all provided with annular chute 1, and several plug-in The outer wall of the seat 5 is extended with an annular slider 7, and each socket 5 is rotated and clamped with the annular chute 1 of each circular port 4 through the annular slider 7, and each socket 5 is provided with Two left and right symmetrical insertion holes 6, each socket 5 is fixedly connected with the live wire insulating plastic sleeve 21 and the neutral wire insulating plastic sleeve 26 through the two insertion hole...

Embodiment 2

[0023] see Figure 1-3 , on the basis of Embodiment 1, a further improvement has been made: the top faces of several receptacles 5 are flush with the top faces of the upper cover 3, so that the plugs of electrical appliances are inserted into the inner cavity of the socket hole 6, and the live wire insulating plastic The top surfaces of the cover 21 and the neutral line insulating plastic cover 26 are flush with the top surface of the receptacle 5, and the purpose of such setting is also to make the plug of the electrical appliance fully inserted into the inner cavity of the live line insulating plastic cover 21 and the neutral line insulating plastic cover 26. , the live wire conductive sleeve 23 and the neutral wire conductive sleeve 24 are made of copper, the thickness of the first arc-shaped pick 22 and the second arc-shaped pick 25 are both 1 mm, and the thickness of the first arc-shaped pick 22 and the second arc pick 25 are 1 mm. Two arc-shaped paddles 25 can not only p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com